How to Select the Best Salt for Cheesemaking is a critical skill for any aspiring cheesemaker. Salt is far more than just a seasoning; it’s a foundational element in cheese production, influencing everything from the final flavor and texture to the cheese’s preservation and safety. Understanding the nuances of salt selection can transform your homemade cheese from good to extraordinary, making it a truly artisanal experience.

This guide dives deep into the world of salt, exploring various types, their chemical compositions, and how their grain size impacts cheese. We’ll unravel the complexities of salting methods, from dry salting to brine salting, and see how salt interacts with cheese cultures and the overall development of flavors. Learn about the role salt plays in preservation, shelf life, and safety and discover how to choose the right salt for your favorite cheese styles.

Introduction: The Importance of Salt in Cheesemaking

Salt is an indispensable ingredient in cheesemaking, playing a multifaceted role that significantly impacts the final product. Its presence influences not only the taste but also the texture, preservation, and overall quality of the cheese. Choosing the right salt is therefore a crucial step in the cheesemaking process, directly affecting the success of the cheese.Salt is not just a flavor enhancer; it is a fundamental component that contributes to the unique characteristics of each cheese type.

This guide explores the different types of salt available and their specific applications in cheesemaking, ensuring you select the most appropriate salt for your desired cheese.

Flavor Development

Salt is a critical flavor component in cheese, enhancing the other flavors present and contributing to the overall taste profile.* Salt directly affects the taste of cheese, providing a salty note that balances other flavors, such as sweetness or acidity.

- The amount of salt used can be adjusted to achieve the desired flavor intensity, from mild to intensely salty.

- Salt can also enhance the perception of other flavors, making them more pronounced and complex. For example, salt can bring out the nuttiness in a cheddar or the tanginess in a feta.

Texture Modification

Salt also significantly influences the texture of cheese, contributing to its firmness, moisture content, and overall mouthfeel.* Salt dehydrates the cheese curds, causing them to shrink and expel whey. This process contributes to a firmer texture.

- Salt controls the rate of moisture loss during aging, influencing how the cheese develops its texture over time.

- The concentration of salt can impact the cheese’s elasticity and melting properties. For example, cheeses with higher salt content tend to melt less easily.

Preservation and Safety

Salt acts as a preservative in cheese, inhibiting the growth of undesirable microorganisms and extending the cheese’s shelf life.* Salt inhibits the growth of spoilage bacteria and molds, helping to prevent the cheese from going bad.

- Salt can also slow down the activity of enzymes that break down the cheese, maintaining its structure and flavor.

- By controlling microbial growth, salt contributes to the safety of the cheese, reducing the risk of foodborne illnesses.

Different Types of Salt for Cheesemaking

There are several types of salt available for cheesemaking, each with its own characteristics and applications. The selection of the right salt type depends on the specific cheese being made and the desired outcome.* Kosher Salt: Kosher salt is a coarse-grained salt that is often favored for cheesemaking because it dissolves easily and doesn’t contain additives. It is also a good choice for brining.

Sea Salt

Sea salt is produced by evaporating seawater and can contain trace minerals that add flavor complexity. Its grain size can vary, affecting how it dissolves and interacts with the cheese.

Dairy Salt

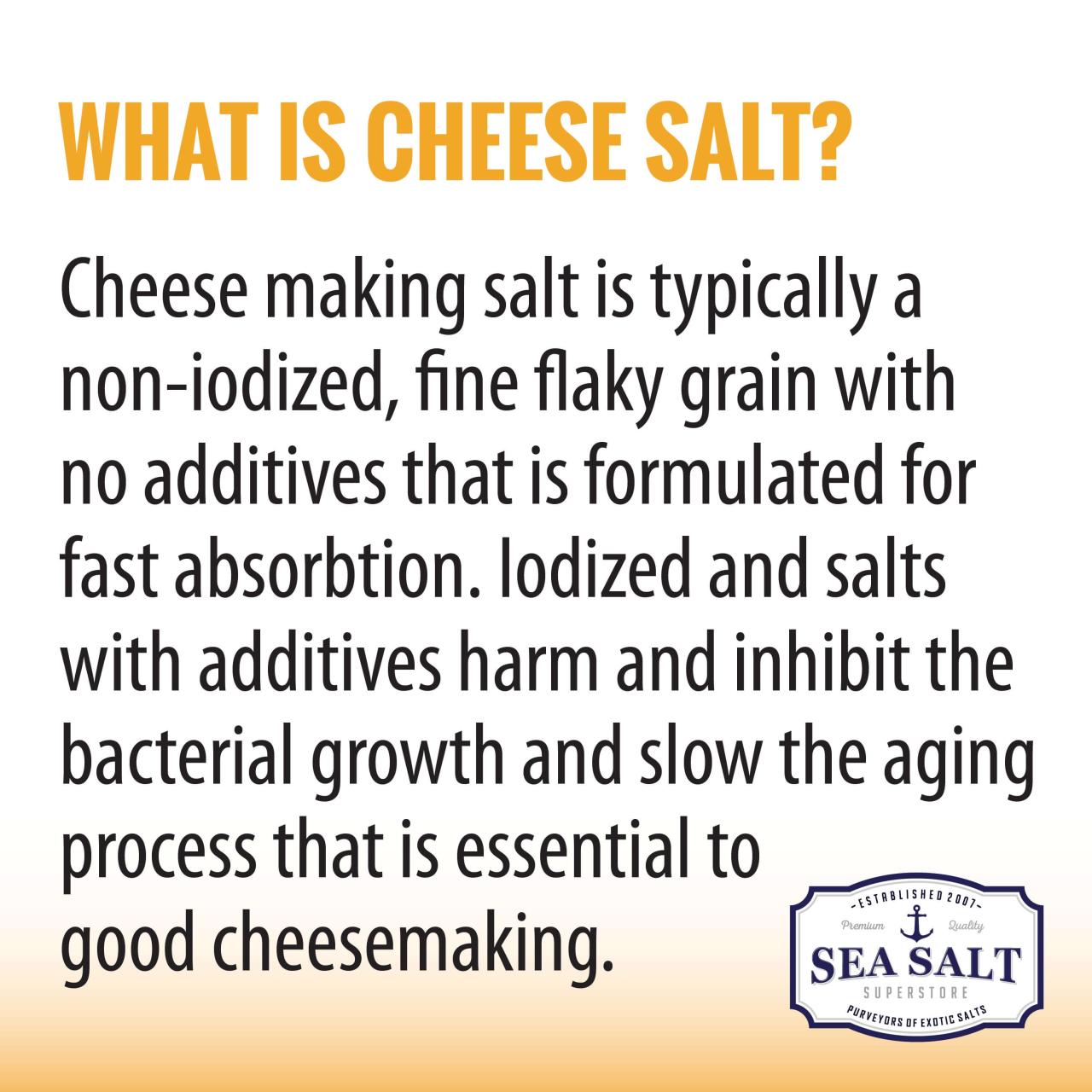

Dairy salt is a finely ground salt specifically designed for cheesemaking. It is often free of additives and designed to dissolve quickly and evenly.

Salt for Brining

Salt for brining is typically kosher or sea salt. The concentration of salt in the brine solution is carefully controlled to achieve the desired flavor and preservation effects.

Significance of Selecting the Correct Salt

The selection of the appropriate salt is crucial for achieving the desired characteristics of the cheese. The wrong type of salt can negatively impact the flavor, texture, and preservation of the cheese.* Using salt with additives can introduce unwanted flavors or affect the cheese’s color and texture.

- The grain size of the salt can affect its solubility and distribution within the cheese, impacting its texture.

- The salt’s purity can influence the cheese’s flavor profile.

“Salt is not just a flavor enhancer; it is a fundamental component that contributes to the unique characteristics of each cheese type.”

Types of Salt Suitable for Cheesemaking

Choosing the right salt is a crucial step in cheesemaking, significantly impacting the final product’s flavor, texture, and overall quality. Different salt types offer unique characteristics, making some more suitable than others for specific cheese styles. Understanding these differences allows cheesemakers to tailor their approach and achieve desired results.

Sea Salt

Sea salt is derived from the evaporation of seawater, resulting in a naturally harvested product. Its mineral composition and crystal structure contribute to its unique properties.Sea salt offers several benefits in cheesemaking:

- Flavor Profile: Sea salt often contains trace minerals, contributing a complex and nuanced flavor profile to the cheese. This can enhance the overall taste experience.

- Texture: The crystal size can vary, influencing the texture of the cheese. Coarser sea salts can create a slightly granular texture, while finer salts dissolve more readily.

- Moisture Control: Salt helps draw moisture out of the cheese curds, aiding in moisture control and contributing to a firmer texture.

However, there are also potential drawbacks:

- Consistency: The mineral content can vary depending on the source, potentially leading to inconsistent results in terms of flavor and salting rates.

- Impurities: Depending on the processing, sea salt may contain impurities. This is generally less of a concern with refined sea salt.

Sea salt is versatile and can be used in various cheese styles:

| Salt Type | Cheese Style Examples | Key Characteristics |

|---|---|---|

| Sea Salt | Cheddar, Feta, Brie | Contains trace minerals, adding complexity. Crystal size affects texture. Good for moisture control. |

Kosher Salt

Kosher salt is a coarse-grained salt, often without additives. It’s popular for its purity and ease of use.Kosher salt’s characteristics include:

- Purity: Typically free of additives like iodine, which can affect cheese flavor.

- Crystal Structure: The irregular shape of the crystals allows them to cling well to surfaces, making it useful for dry-salting cheeses.

- Dissolving Rate: Kosher salt dissolves relatively quickly, making it suitable for brining and salting curds.

Considerations when using kosher salt:

- Crystal Size Variation: Different brands may have varying crystal sizes, affecting the salting rate. Always consider the brand used.

- Density: The density of kosher salt can differ from other salt types, so measuring by weight is recommended for accurate results.

Kosher salt is well-suited for a variety of cheese styles:

| Salt Type | Cheese Style Examples | Key Characteristics |

|---|---|---|

| Kosher Salt | Monterey Jack, Gouda, Havarti | Pure, additive-free. Irregular crystal shape for good adhesion. Dissolves quickly. |

Pickling Salt

Pickling salt is a fine-grained, pure salt, often used in preserving foods. It is known for its complete solubility.Key features of pickling salt include:

- Purity: Free of additives like iodine and anti-caking agents, which can negatively affect the clarity of brine solutions or cheese flavor.

- Solubility: Dissolves completely and rapidly in water, making it ideal for creating clear brine solutions.

- Uniformity: The fine grain size provides a consistent salting rate.

Potential drawbacks include:

- Lack of Trace Minerals: Lacking the trace minerals found in some sea salts, it may not contribute to complex flavor profiles.

Pickling salt’s uses extend to:

| Salt Type | Cheese Style Examples | Key Characteristics |

|---|---|---|

| Pickling Salt | Mozzarella, Ricotta, Halloumi (brined) | Pure, additive-free, and dissolves completely. Ideal for brining. Provides consistent salting rates. |

Flake Salt

Flake salt is produced through a controlled evaporation process, resulting in delicate, irregularly shaped flakes. It’s prized for its texture and finishing qualities.Characteristics of flake salt:

- Texture: The flaky structure provides a satisfying crunch and dissolves quickly on the tongue.

- Flavor: Offers a clean, intense salty taste that can enhance the flavor of the cheese.

- Appearance: Adds visual appeal when used as a finishing salt.

Potential downsides:

- Cost: Generally more expensive than other salt types.

- Moisture Absorption: Flake salt can absorb moisture, so it needs to be stored properly.

Flake salt is commonly used for:

| Salt Type | Cheese Style Examples | Key Characteristics |

|---|---|---|

| Flake Salt | Cheeses where surface texture is desired, e.g., some hard cheeses as a finishing salt | Provides a satisfying crunch and intense salty taste. Adds visual appeal. Best used as a finishing salt. |

Understanding Salt Composition and Purity

Selecting the right salt for cheesemaking goes beyond simply choosing between flake or granular forms. A deep understanding of salt’s chemical composition and the potential impact of impurities is crucial for achieving consistent results and the desired flavor profile in your cheeses. This section delves into the specifics of salt purity and its role in the cheesemaking process.

Salt’s Chemical Makeup

Salt, in its purest form, is composed of sodium chloride (NaCl). This simple compound is the foundation of salt’s functionality in cheesemaking. However, the purity of salt varies depending on its source and processing.

Sodium Chloride (NaCl)

is the primary component, providing the essential salty flavor and acting as a preservative. It controls moisture content and inhibits the growth of undesirable bacteria.

Impurities in Salt and Their Impact

Salt often contains trace elements and minerals that can affect the cheesemaking process. These impurities can arise from the salt’s source (e.g., seawater, underground deposits) or be introduced during processing. Understanding these impurities is key to selecting the most suitable salt.

- Calcium and Magnesium: These minerals, often present in sea salt, can influence the rate of moisture loss and potentially affect the texture of the cheese. Excessive amounts can lead to a harder cheese rind.

- Sulfates: Sulfates can contribute a slightly bitter taste to the cheese and, in high concentrations, might interfere with the activity of starter cultures.

- Other Trace Minerals: Depending on the source, salt can contain trace amounts of iron, copper, and other elements. While generally present in small quantities, these can sometimes affect the color and flavor development of the cheese, though their impact is usually minimal.

Importance of Minimal Additives

Choosing salt with minimal additives is vital for maintaining control over the cheesemaking process. Additives are often included to improve the salt’s flowability, prevent caking, or add iodine. However, these additives can sometimes interfere with the delicate balance of the cheesemaking environment.

Common Salt Additives and Their Potential Effects

Several additives are commonly found in table salt. These can influence the cheesemaking process, either positively or negatively, depending on the type of cheese and the quantity of the additive.

- Anti-caking agents: Such as sodium aluminosilicate or calcium silicate, are added to prevent salt from clumping. While generally inert, some cheesemakers avoid them, fearing they might subtly affect culture activity or cheese texture.

- Iodine: Added as potassium iodide or sodium iodide to prevent iodine deficiency, iodized salt is often avoided in cheesemaking. Iodine can inhibit the activity of starter cultures, particularly in cheeses with long ripening times.

- Dextrose or Sugar: Sometimes added in small amounts as a stabilizer or flavor enhancer. While generally not a significant concern, these can contribute to unwanted microbial activity if present in large quantities.

- Fluoride: Similar to iodine, some salts are fluoridated. While not as common as iodized salt, fluoride can also potentially influence the starter cultures, depending on the concentration.

Salt Granulation and its Impact

The size of salt crystals, or granulation, plays a significant role in cheesemaking. It affects how the salt interacts with the cheese curd, influencing moisture removal, texture development, and overall cheese appearance. Understanding these nuances allows cheesemakers to fine-tune their process and achieve desired results for various cheese types.

Salt Grain Size and Moisture Removal

The rate at which salt draws moisture from the cheese curd is directly influenced by its grain size.The surface area of the salt crystals determines the speed of moisture extraction. Finer salt has a greater surface area per unit of weight compared to coarser salt. This increased surface area allows for quicker moisture absorption from the curd. Conversely, coarser salt, with a smaller surface area, extracts moisture more slowly.

This difference is critical during the salting process, impacting the cheese’s internal moisture content and resulting texture.

Salt Grain Size and Texture/Appearance

Salt grain size affects the final texture and appearance of the cheese.

- Fine Salt: Fine salt, like table salt or fine sea salt, dissolves quickly and penetrates the curd uniformly. This results in a more even moisture distribution throughout the cheese, often leading to a smoother, more compact texture. The surface of the cheese might appear smoother and less textured.

- Coarse Salt: Coarse salt, such as kosher salt or large flake salt, dissolves more slowly. This slower dissolution creates a gradient of salt concentration within the cheese, potentially contributing to a more varied texture. Coarse salt can also create a slightly rougher surface on the cheese, especially if applied directly. In some cheeses, this texture is desirable, contributing to a unique mouthfeel.

Salt Grain Size Suitability for Cheese Types

The appropriate salt grain size depends on the specific cheese being made.Salt selection is a key decision point for cheesemakers, and it is crucial to consider the type of cheese, the desired texture, and the salting method. The following comparison provides guidance:

- Soft Cheeses (e.g., Brie, Camembert): Generally, fine or medium-grained salt is preferred. The goal is even salting to prevent excessive moisture loss and promote the growth of surface molds. A uniform texture is often desired.

- Semi-Hard Cheeses (e.g., Cheddar, Gouda): Medium or coarse salt can be used, depending on the desired texture and salting method (e.g., dry salting or brine salting). The salt’s slower dissolution in dry salting can contribute to flavor development and texture variation.

- Hard Cheeses (e.g., Parmesan, Gruyère): Coarse salt is often employed, particularly for surface salting. This can create a more robust rind and a slightly uneven texture, contributing to the cheese’s character.

- Brine Salting: The salt grain size is less critical in brine salting, as the salt is already dissolved. However, the purity of the salt used to make the brine remains important.

| Salt Grain Size | Characteristics | Suitable Cheese Types | Impact on Cheese |

|---|---|---|---|

| Fine (e.g., Table Salt) | Small particles, dissolves quickly, high surface area | Soft cheeses, some brine applications | Even salting, smoother texture, faster moisture removal |

| Medium (e.g., Kosher Salt) | Moderate particle size, moderate dissolution rate | Semi-hard cheeses, some brining | Moderate moisture removal, balanced texture |

| Coarse (e.g., Flake Salt) | Large particles, slow dissolution, lower surface area | Hard cheeses, surface salting | Slower moisture removal, varied texture, rind formation |

Methods of Salting Cheese

Salting cheese is a crucial step in the cheesemaking process, impacting flavor, texture, and preservation. The choice of salting method depends on the cheese type, desired characteristics, and available equipment. Several methods exist, each with its advantages and disadvantages. Understanding these methods allows cheesemakers to control the final product effectively.

Dry Salting

Dry salting involves directly applying salt to the cheese surface. This method is often used for hard cheeses and cheeses with a rind.Advantages:

- Simple and requires minimal equipment.

- Promotes rind formation, which helps protect the cheese during aging.

- Can control salt penetration more precisely.

Disadvantages:

- Salt penetration can be uneven, potentially leading to inconsistent flavor and texture.

- Requires careful monitoring to prevent excessive salt uptake, which can result in a dry, salty cheese.

- Can be labor-intensive, particularly for large batches.

Brine Salting

Brine salting involves submerging the cheese in a salt solution. This method is suitable for various cheese types, including soft and semi-hard cheeses.Advantages:

- Provides even salt distribution throughout the cheese.

- Offers a more controlled and consistent salting process.

- Less labor-intensive compared to dry salting, especially for large batches.

Disadvantages:

- Requires preparing and maintaining a brine solution.

- Can lead to salt loss from the cheese if the brine concentration is not properly maintained.

- May require specialized equipment, such as a brine tank.

Combined Methods

Some cheesemakers combine dry salting and brine salting, using dry salting initially to encourage rind formation and then brine salting to finish the salting process.Advantages:

- Combines the benefits of both methods, allowing for a balance between rind formation and even salt distribution.

- Offers flexibility in controlling the final salt content and texture.

Disadvantages:

- Requires more time and effort than either dry salting or brine salting alone.

- Demands careful monitoring and adjustments to both salting stages.

Procedure for Brine Salting

Brine salting requires a well-maintained brine solution. Proper concentration and maintenance are critical for success. Here’s a detailed procedure:

- Brine Concentration Calculation: The desired salt concentration in the brine typically ranges from 18% to 24% by weight, depending on the cheese type. The concentration of the brine can be measured using a hydrometer specifically designed for salt solutions.

Example: For a 20% brine solution, you need 200 grams of salt per liter of water (or 200g salt + 800g water).

- Brine Preparation:

- Dissolve the calculated amount of food-grade salt in clean, potable water. Use non-iodized salt.

- Stir the solution thoroughly until the salt is completely dissolved.

- Allow the brine to sit for a few hours or overnight to ensure complete saturation and to allow any undissolved particles to settle.

- Filter the brine to remove any sediment.

- Brining the Cheese:

- Submerge the cheese completely in the prepared brine solution. Ensure the cheese is fully covered.

- Maintain the brine temperature at the recommended level for the cheese type. A typical range is between 10-15°C (50-59°F). Lower temperatures slow down the cheese’s enzymatic activity, which affects its flavor and texture.

- The brining time depends on the cheese type and desired salt content. Monitor the cheese regularly. Soft cheeses typically brine for a shorter time than hard cheeses.

- Brine Maintenance:

- Regularly check the brine concentration using a hydrometer. Adjust the concentration by adding salt or water as needed. Salt is removed from the brine as it is absorbed by the cheese.

- Monitor the brine for any signs of spoilage, such as cloudiness or off-odors. If the brine becomes contaminated, it should be discarded and replaced with a fresh batch.

- Clean the brine tank regularly to prevent the buildup of mold or bacteria.

- Add calcium chloride (0.1% to 0.2% of the brine volume) to the brine solution, which can help firm up the cheese and prevent it from softening excessively.

- Post-Brining:

- Remove the cheese from the brine and allow it to drain.

- Dry the cheese surface, which is often done in a cheese cave with controlled humidity and temperature.

- Age the cheese according to the specific recipe and desired characteristics.

Salt and Cheese Flavor Development

Salt is a critical ingredient in cheesemaking, and its role extends far beyond just adding a salty taste. It plays a pivotal role in shaping the complex flavor profiles that make each cheese unique. The amount and type of salt used, along with how it’s incorporated, directly influence the chemical and biological processes that occur during cheese aging, ultimately determining the final flavor, texture, and overall quality of the cheese.

Salt’s Contribution to Specific Cheese Flavors

Salt influences flavor development by controlling the activity of enzymes and microorganisms within the cheese. These interactions are crucial for breaking down proteins and fats, which release flavor compounds.Salt achieves this in several ways:

- Controlling Moisture Content: Salt draws out moisture, which concentrates the flavor compounds and impacts the texture. This drying effect also slows down unwanted microbial activity.

- Inhibiting Undesirable Microorganisms: Salt inhibits the growth of spoilage bacteria and certain undesirable molds. This creates a more favorable environment for the beneficial bacteria and molds that contribute to desired flavors.

- Influencing Enzyme Activity: Salt can either activate or inhibit the activity of enzymes, depending on the specific enzyme and salt concentration. Enzymes are responsible for breaking down proteins (proteolysis) and fats (lipolysis), leading to the formation of flavor compounds. For example, higher salt concentrations often slow down proteolysis, leading to a firmer texture and a less intense flavor in some cheeses.

- Direct Flavor Contribution: Salt itself provides a fundamental salty taste, which balances other flavors and enhances the overall complexity.

Interaction Between Salt and Cheese Cultures in Flavor Production

The interaction between salt and the cheese cultures (bacteria and molds) is a dynamic process that significantly impacts flavor. The salt concentration affects the growth and metabolic activity of these cultures, which in turn influences the flavor development.Here’s how this interaction works:

- Culture Selection: Different cheese cultures have varying salt tolerances. The cheesemaker selects cultures that are well-suited to the planned salt level.

- Salt’s Effect on Culture Growth: Salt can either inhibit or promote the growth of specific cultures. For instance, some lactic acid bacteria are salt-sensitive, while others, like

-Brevibacterium linens* (used in washed-rind cheeses), thrive in higher salt environments. - Metabolic Activity: The metabolic activity of the cultures is also affected by salt. They produce different flavor compounds depending on the salt concentration.

- Example: In washed-rind cheeses, the high salt content on the rind encourages the growth of

-B. linens*, which produces compounds that contribute to the cheese’s characteristic pungent aroma and flavor.

How Salt Levels Influence the Final Flavor Profile of Different Cheese Varieties

The salt level is a key factor in defining the flavor profiles of different cheese varieties. Cheesemakers carefully control the salt concentration to achieve the desired flavor characteristics.Here are some examples:

- Fresh Cheeses (e.g., Feta, Cottage Cheese): These cheeses typically have a higher salt content, contributing to their sharp, salty taste and preserving them. Feta, for instance, is often brined, resulting in a high salt concentration throughout the cheese.

- Soft-Ripened Cheeses (e.g., Brie, Camembert): These cheeses generally have a lower salt content compared to fresh cheeses. The lower salt allows the mold

-Penicillium candidum* to grow on the surface, creating a creamy texture and a mild, mushroomy flavor. The salt is often added by dry salting or in a brine. - Semi-Hard Cheeses (e.g., Cheddar, Gouda): These cheeses typically have a moderate salt content. Salt slows down the activity of the starter cultures and enzymes, which contributes to a slower aging process and a more complex flavor development over time. The salt is usually added during the cheesemaking process, such as during the curd stage.

- Hard Cheeses (e.g., Parmesan, Gruyère): These cheeses often have a moderate to high salt content. The salt helps to control moisture, inhibit unwanted bacteria, and promote the development of complex flavors during the long aging process. The extended aging also contributes to the concentration of flavor compounds. Salt is often added during the cheesemaking process, or by brining.

- Blue Cheeses (e.g., Roquefort, Gorgonzola): Blue cheeses often have a moderate salt content, and the salt also inhibits the growth of unwanted molds and bacteria while allowing the blue mold (*Penicillium roqueforti*) to flourish. The salt can be added to the curd, or the cheese may be brined.

In each case, the specific salt level is carefully calibrated to work in synergy with the chosen cultures and aging conditions to create the characteristic flavors and textures of the cheese.

Salt and Cheese Texture

Salt plays a crucial role in determining the final texture of cheese, influencing its firmness, elasticity, and overall mouthfeel. The way salt interacts with the protein matrix and affects moisture content significantly impacts the textural characteristics, contributing to the diverse range of cheese textures we enjoy.

Salt’s Influence on Protein Structure

Salt’s interaction with the proteins in milk, primarily casein, is fundamental to cheese texture. This interaction influences the formation and structure of the protein network.

- Calcium Binding: Salt competes with calcium ions for binding sites on casein micelles. This competition affects the strength and structure of the protein network. Higher salt concentrations can lead to a weaker network, resulting in a softer cheese.

- Protein Hydration: Salt affects the hydration of proteins. It can dehydrate the proteins, leading to a tighter protein network and a firmer texture. However, excessive dehydration can result in a dry, crumbly cheese.

- Enzyme Activity: Salt also influences the activity of enzymes, such as rennet and those naturally present in milk. These enzymes are crucial for the initial coagulation and subsequent breakdown of proteins, which affects texture development.

Impact of Salt Concentration on Moisture and Texture

The concentration of salt directly affects the moisture content and, consequently, the texture of cheese. The osmotic effect of salt draws moisture out of the cheese curds, leading to a drier cheese.

- Lower Salt Concentration: Lower salt levels retain more moisture, resulting in a softer, more pliable texture. Examples include fresh cheeses like ricotta or cream cheese.

- Moderate Salt Concentration: Moderate salt levels provide a balance, allowing for some moisture loss and a firmer texture. Cheeses like cheddar and Gouda fall into this category.

- Higher Salt Concentration: Higher salt concentrations draw out more moisture, leading to a firmer, drier texture. This is often seen in aged cheeses like Parmesan or feta, where the texture becomes hard and sometimes crystalline.

Visual Representation of Textural Changes with Varying Salt Levels

The following is a description of the textural changes observed in cheese with varying salt levels. This visual representation uses descriptive text to convey the changes.

- Low Salt Cheese: Imagine a soft, almost spreadable cheese. Its surface is smooth and slightly glossy due to high moisture content. When gently pressed, it yields easily, leaving a slight indentation. The texture is creamy and moist, with a subtle, mild flavor. Think of a very young mozzarella.

- Moderate Salt Cheese: Picture a cheese with a firmer body, still pliable but with some resistance. The surface is smoother, with a slight sheen. When pressed, it offers some resistance, and the indentation slowly springs back. The texture is firm yet elastic, with a balanced flavor. Consider a well-aged cheddar.

- High Salt Cheese: Visualize a firm, almost hard cheese. The surface might appear drier, with possible cracks or crystalline formations. When pressed, it offers significant resistance, and the indentation does not remain. The texture is hard, possibly crumbly or crystalline, with a strong, concentrated flavor. Parmesan is a prime example.

Salt’s Role in Preservation and Safety

Salt is a cornerstone of cheesemaking, not just for flavor and texture, but also for its critical role in preserving the cheese and ensuring its safety. Its ability to control microbial growth is essential in transforming milk into a stable and edible product. Understanding how salt achieves this is vital for every cheesemaker.

Inhibition of Undesirable Microorganisms

Salt acts as a powerful preservative by selectively inhibiting the growth of spoilage and pathogenic microorganisms. This selective action is crucial for directing the fermentation process and ensuring the cheese is safe to consume.Salt achieves this in several ways:

- Dehydration: Salt draws water out of microbial cells through osmosis. This process, called plasmolysis, dehydrates the cells, effectively stopping their metabolic processes and preventing them from multiplying.

- Enzyme Inhibition: Salt can interfere with the activity of enzymes essential for microbial survival and growth. Without these enzymes, microorganisms cannot function properly.

- pH Modification: Salt can slightly influence the pH of the cheese environment, making it less favorable for the growth of many undesirable microorganisms. While the effect is generally minor compared to other factors, it can contribute to the overall preservation.

These mechanisms collectively contribute to a safer and more stable cheese product. For example, in the production of hard cheeses like cheddar, the high salt content (typically 1.5-2.5% by weight) significantly inhibits the growth of undesirable bacteria, contributing to the cheese’s long shelf life and preventing spoilage.

Relationship Between Salt Concentration and Cheese Shelf Life

The concentration of salt in cheese directly influences its shelf life. Higher salt concentrations generally lead to longer shelf lives, as they provide a more effective barrier against microbial growth. However, the optimal salt concentration is a delicate balance, as excessive salt can negatively impact flavor and texture.The shelf life of cheese varies considerably depending on the type and its salt content.

Consider these examples:

- Fresh Cheeses (e.g., Feta): These cheeses typically have higher salt concentrations (often 3-5% in the brine) and shorter shelf lives compared to aged cheeses. The high salt content is critical for preventing the growth of spoilage organisms in the moist environment.

- Semi-Hard Cheeses (e.g., Gouda): These cheeses have moderate salt concentrations (typically 1.5-2.0%) and a longer shelf life than fresh cheeses. The salt helps control the ripening process and extends the cheese’s edibility.

- Hard Cheeses (e.g., Parmesan): Hard cheeses often have lower moisture content and higher salt concentrations (1.5-2.5%). This combination contributes to their extended shelf life, which can be years under proper storage conditions.

It is important to remember that shelf life is also influenced by other factors, such as moisture content, pH, and storage temperature. However, salt concentration remains a primary determinant.

Safety Aspects of Using Salt in Cheesemaking

While salt is essential for cheesemaking, its use must be approached with attention to safety. Both the purity of the salt and the practices employed during its use are critical.Here are some important considerations:

- Salt Purity: Always use food-grade salt specifically designed for cheesemaking. Avoid salt with additives, such as iodine or anti-caking agents, which can negatively impact the cheese’s flavor, texture, or microbial activity.

- Source of Salt: Ensure the salt source is reliable and reputable, and that the salt is free from contaminants.

- Storage: Store salt in a dry, airtight container to prevent clumping and contamination. Proper storage also helps maintain the salt’s purity.

- Dosage Control: Accurately measure the salt when incorporating it into the cheese. Using too much or too little salt can compromise the cheese’s flavor, texture, and safety. Follow the recipe guidelines precisely.

- Hygiene: Maintain strict hygiene practices throughout the cheesemaking process, including using clean equipment and sanitizing all surfaces that come into contact with the salt or cheese. This prevents cross-contamination.

Following these best practices will help ensure that salt contributes to the safety and quality of your cheese.

Selecting Salt Based on Cheese Type

Choosing the right salt is crucial for achieving the desired characteristics of a specific cheese. Different cheese styles have unique requirements in terms of moisture content, aging time, and flavor profiles, all of which influence the optimal salt selection and salting method. This section delves into how to tailor salt choices to various cheese types, ensuring successful cheesemaking.

Appropriate Salt Choices for Different Cheese Styles

The selection of salt should be aligned with the cheese’s characteristics. For example, hard cheeses require different salting strategies compared to soft cheeses.Here are some examples:

- Cheddar: Typically uses dry salting with fine or medium-grained salt. The salt is added directly to the milled curds, influencing moisture removal and flavor development. The size of the salt granules affects the rate of moisture extraction.

- Brie: Often employs dry salting on the surface of the cheese. Fine salt is typically used, sometimes combined with a starter culture, to encourage the growth of the bloomy rind.

- Feta: Brine salting is the most common method for Feta. The cheese is submerged in a high-salinity brine solution. The salt concentration in the brine is critical for preservation and flavor.

- Mozzarella: Often uses a combination of salting methods. The curd is often salted during the stretching process, and then the finished cheese may be brined.

- Parmesan: Dry salting with coarse salt is used. The large salt crystals contribute to the cheese’s firm texture and prolonged aging process. The salt is applied to the surface of the cheese.

Comparing Salting Methods and Salt Types in Cheese-Making

The salting method employed significantly affects the final cheese.Here’s a comparison of salting methods and salt types across various cheese-making examples:

| Cheese Type | Salting Method | Salt Type | Key Considerations |

|---|---|---|---|

| Cheddar | Dry salting (to milled curds) | Fine or medium-grained salt | Influences moisture content, rate of flavor development, and texture. Salt size impacts moisture removal. |

| Brie | Dry salting (surface) | Fine salt | Promotes rind development and controls surface moisture. Sometimes combined with starter cultures. |

| Feta | Brine salting | Salt for brine solution | Brine concentration is crucial for preservation, texture, and flavor. The salt used should be food grade and free of additives. |

| Mozzarella | Salting during stretching, then brine (optional) | Fine salt | Salt impacts the stretch and melt characteristics of the cheese. |

| Parmesan | Dry salting (surface) | Coarse salt | Contributes to firm texture and aids in the prolonged aging process. Large crystals are used to control moisture and provide a specific flavor profile. |

Considerations for Selecting Salt Based on Cheese Type

The selection of salt must consider various factors. These factors include moisture content, aging time, and desired flavor profile.

- Moisture Content: Cheeses with higher moisture content, like Feta, often benefit from brine salting to ensure even salt distribution and preservation. Drier cheeses, such as Parmesan, are typically dry-salted.

- Aging Time: Longer-aged cheeses, such as Parmesan, often use coarser salt and slower salting methods to control moisture and flavor development over time.

- Desired Flavor Profile: The type of salt and salting method influence the final flavor. For example, brine salting in Feta provides a salty, tangy flavor.

- Surface Rind Development: For cheeses like Brie, the type of salt, and its application method, directly affect the development of the bloomy rind.

Sourcing and Storing Salt for Cheesemaking

Sourcing and storing salt correctly is as crucial as understanding its role in cheesemaking. The quality of your final product hinges on the purity and handling of this essential ingredient. Proper sourcing ensures you begin with the right salt, and appropriate storage preserves its characteristics, preventing unwanted changes that can affect your cheese.

Factors to Consider When Purchasing Salt for Cheesemaking

Choosing the right salt for cheesemaking goes beyond simply grabbing the first container you see. Several factors impact the final quality of your cheese, influencing everything from flavor to texture and shelf life. A careful selection process is essential for achieving consistent results.

- Source of Salt: The origin of your salt is a primary indicator of its potential quality. Salt can come from various sources, including:

- Sea Salt: Harvested from evaporated seawater, sea salt can contain trace minerals that contribute to flavor complexity. However, it can also contain impurities if not properly processed.

- Rock Salt (Mined Salt): Extracted from underground salt deposits, rock salt is generally purer than sea salt, but its mineral composition can vary depending on the deposit.

- Solar Salt: This type of salt is produced by evaporating saltwater in large, shallow ponds, often in coastal areas. It tends to be relatively pure and has a consistent crystal structure.

- Brine Salt: Extracted by dissolving underground salt deposits with water and then evaporating the resulting brine. This process can produce a highly pure salt.

- Salt Grade and Purity: Look for salt specifically labeled for food use, preferably with a high purity level (typically 99% sodium chloride or higher). The grade of salt (e.g., food grade, kosher) indicates the level of processing and the intended use.

- Additives: Check the ingredient list for additives. While some additives are harmless, others, like iodine (added to iodized salt), can negatively affect cheese flavor. Avoid salt with anti-caking agents, as these can also interfere with cheesemaking processes.

- Manufacturer’s Reputation and Quality Control: Choose salt from a reputable manufacturer with established quality control procedures. Look for information about their processing methods and any certifications they hold (e.g., ISO 9001). This helps ensure consistency and minimizes the risk of contamination.

- Packaging: The packaging should be airtight and moisture-proof to protect the salt from environmental contaminants. Consider the size of the packaging based on your cheesemaking volume. Bulk purchases can be cost-effective but require proper storage to prevent spoilage.

Recommendations for Proper Salt Storage

Proper storage of salt is crucial for maintaining its quality and preventing contamination. Salt is hygroscopic, meaning it readily absorbs moisture from the air, which can lead to clumping and dissolving. Follow these guidelines to ensure your salt remains in optimal condition.

- Container: Store salt in an airtight, moisture-proof container. Food-grade plastic containers with tight-fitting lids are ideal. Glass jars are another option, but ensure the lids seal well.

- Location: Keep the container in a cool, dry place away from direct sunlight and heat sources. A pantry or cupboard is usually a good choice. Avoid storing salt near sources of moisture, such as sinks or dishwashers.

- Temperature and Humidity: Maintain a consistent temperature and low humidity level. Fluctuations in temperature and humidity can cause the salt to absorb moisture and clump.

- Prevent Contamination: Never use wet utensils to scoop salt. Always use a clean, dry spoon or scoop. Regularly clean the storage container to prevent the buildup of dust or other contaminants.

- Labeling: Clearly label the container with the type of salt, the date of purchase, and the expiration date (if applicable). This helps with inventory management and ensures you use the freshest salt.

- Bulk Storage Considerations: If purchasing salt in bulk, store it in its original packaging or transfer it to a large, food-grade container. Ensure the container is properly sealed to prevent moisture absorption. Consider using a desiccant, such as silica gel packets, to absorb excess moisture in humid environments.

Checklist for Evaluating Salt Quality Before Use

Before using salt in your cheesemaking process, perform a quick quality check to ensure it meets your standards. This checklist helps identify potential problems that could negatively affect your cheese.

- Visual Inspection: Examine the salt for any visible signs of contamination, such as dirt, insects, or foreign particles. The salt should appear clean and free-flowing.

- Clumping: Check for clumping or hardening. Small amounts of clumping are acceptable, but excessive clumping indicates moisture absorption and potential quality issues. If the salt is severely clumped, it may not be suitable for use.

- Odor: Smell the salt for any unusual odors. Off-odors can indicate contamination or the presence of unwanted substances. The salt should have a neutral or slightly salty smell.

- Taste Test (Optional): If you are unsure about the salt’s quality, you can perform a taste test. Dissolve a small amount of salt in water and taste the solution. The taste should be clean and salty, without any bitter or metallic notes.

- Solubility: Test the salt’s solubility by dissolving a small amount in water. It should dissolve readily and completely. Incomplete solubility can indicate the presence of insoluble impurities.

- Packaging Integrity: Ensure the packaging is intact and sealed properly. Any damage to the packaging can compromise the salt’s quality.

- Expiration Date: Check the expiration date (if applicable) and use the salt before it expires.

Wrap-Up

In conclusion, selecting the right salt is a cornerstone of successful cheesemaking. From understanding salt composition to mastering salting techniques, the journey is one of exploration and refinement. By carefully considering salt type, grain size, and salting method, you can unlock a world of flavor and texture possibilities, ensuring your homemade cheeses are not only delicious but also safe and long-lasting.

Embrace the power of salt and elevate your cheesemaking to new heights!