Embark on a flavorful journey with How to Vacuum Seal Cheese for Aging, a process that transforms ordinary cheese into exquisite culinary delights. This guide unveils the secrets behind extending the shelf life and enhancing the taste of your favorite cheeses, turning your kitchen into a mini-affineur’s paradise. From understanding the science behind vacuum sealing to mastering the art of aging, we’ll equip you with the knowledge to create aged cheese masterpieces at home.

Vacuum sealing cheese is more than just preserving it; it’s about controlling the aging environment to coax out complex flavors and textures. We’ll explore the benefits of this method, including moisture control and mold prevention, and guide you through selecting the right cheese types, preparing them for sealing, and choosing the appropriate equipment. Get ready to elevate your cheese game and impress your friends and family with your newfound skills.

Understanding the Benefits of Vacuum Sealing Cheese for Aging

Vacuum sealing cheese is a crucial step in the aging process, offering significant advantages over traditional methods. This technique creates an environment that promotes desirable flavor and texture development while simultaneously preventing spoilage. Understanding these benefits is key to successfully aging cheese at home and achieving optimal results.

Moisture Control and Mold Prevention

Vacuum sealing plays a vital role in managing moisture levels and preventing unwanted mold growth, crucial for the cheese aging process. By removing air, the environment inside the vacuum-sealed bag is drastically altered.Vacuum sealing minimizes the presence of oxygen, which is essential for the growth of most molds. This controlled environment is especially important because:

- Reduced Mold Growth: Vacuum sealing creates an anaerobic environment, which significantly inhibits the growth of common molds that can spoil cheese. This is in stark contrast to aging cheese in a refrigerator or open environment, where mold growth is a constant concern.

- Controlled Moisture Loss: The vacuum seal helps regulate moisture loss from the cheese. Excessive drying can lead to a hard, crumbly texture, while insufficient drying can promote unwanted bacterial growth. The seal allows for a slow, controlled release of moisture, promoting the desired texture development for each cheese type.

- Reduced Cross-Contamination: Vacuum sealing helps prevent the spread of unwanted molds and bacteria. This is particularly important when aging multiple cheeses simultaneously.

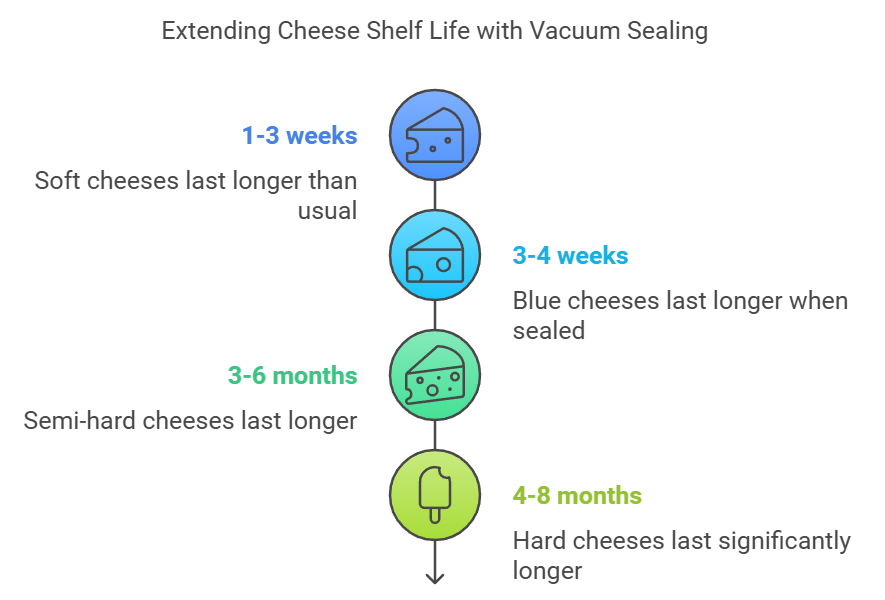

Shelf Life Extension Compared to Other Methods

Vacuum sealing dramatically extends the shelf life of cheese during the aging process compared to methods like wrapping in wax paper or storing in the refrigerator. This difference stems from the controlled environment created by vacuum sealing.Compared to other methods, vacuum sealing offers a superior environment for aging cheese.

- Wax Paper Wrapping: While wax paper can provide some protection, it doesn’t create an airtight seal. This can lead to moisture loss, mold growth, and a shorter aging period. Cheese aged in wax paper often requires more frequent monitoring and may not achieve the same level of flavor development.

- Refrigerator Storage: Refrigerator storage, even when using plastic wrap, exposes the cheese to fluctuating temperatures and potential contamination from other foods. This can lead to uneven aging and spoilage. The refrigerator environment also allows some mold growth.

- Vacuum Sealing: Vacuum sealing provides a consistently controlled environment. The removal of air minimizes oxidation, retards mold growth, and allows for a more predictable and extended aging process. The shelf life can be significantly extended, often by several months, compared to other methods.

Impact on Flavor Development and Texture Changes

Vacuum sealing directly influences the flavor development and texture changes that occur during cheese aging. The absence of oxygen and the controlled moisture environment are key factors in shaping these transformations.The flavor and texture changes are dependent on the cheese type and aging process.

- Flavor Concentration: By controlling moisture loss and minimizing oxidation, vacuum sealing can lead to a concentration of flavors. This is particularly noticeable in hard cheeses, where the flavors become more intense over time.

- Texture Modification: The texture of the cheese also changes. Some cheeses become firmer and more crystalline, while others develop a creamier texture. The specific changes depend on the cheese variety and the aging conditions. For example, a cheddar cheese aged in a vacuum-sealed bag will typically become sharper and develop a more crumbly texture, while a brie might become softer and more pungent.

- Enzyme Activity: The anaerobic environment created by vacuum sealing can influence the activity of enzymes within the cheese. These enzymes break down proteins and fats, contributing to the complex flavors and textures characteristic of aged cheese. The controlled environment promotes the desired enzymatic reactions, leading to optimal flavor development.

Selecting the Right Cheese for Vacuum Sealing and Aging

Choosing the correct cheese is crucial for successful vacuum sealing and aging. Not all cheeses are created equal when it comes to this process. Some varieties age beautifully, developing complex flavors and textures, while others may become unpalatable or even unsafe. Understanding the characteristics of different cheese types is key to achieving the desired results.

Suitable and Unsuitable Cheese Types

The suitability of cheese for vacuum sealing and aging depends heavily on its composition and characteristics. Certain cheese types respond well to the controlled environment created by vacuum sealing, while others do not.

- Suitable Cheeses: Hard and semi-hard cheeses are generally well-suited for vacuum sealing and aging. These cheeses have lower moisture content, which inhibits the growth of undesirable microorganisms. Examples include:

- Cheddar

- Parmesan

- Gouda

- Swiss

- Provolone

- Manchego

- Unsuitable Cheeses: Soft and fresh cheeses are generally not recommended for vacuum sealing and aging. Their high moisture content and often delicate structures make them prone to spoilage and undesirable textural changes. Examples include:

- Brie

- Camembert

- Feta

- Mozzarella

- Ricotta

- Cream Cheese

Factors to Consider When Choosing Cheese for Aging

Several factors influence a cheese’s suitability for aging, especially when vacuum sealing is involved. Paying attention to these aspects will significantly impact the outcome.

- Moisture Content: Lower moisture content is generally preferable for aging. High moisture content encourages the growth of mold and bacteria, which can lead to spoilage or undesirable flavors. Hard cheeses naturally have lower moisture content than soft cheeses.

- Rind Type: The rind plays a vital role in the aging process. Some cheeses have natural rinds, while others are coated or waxed. The rind acts as a barrier, controlling moisture loss and allowing for the development of complex flavors. The presence of a natural rind is often an advantage.

- Cheese Composition: The type of milk (cow, goat, sheep, etc.), the fat content, and the presence of added cultures all influence how a cheese ages. The specific cultures used contribute to the development of unique flavors and textures.

- Age of Cheese at Vacuum Sealing: Starting with a cheese that has already undergone some aging can be beneficial. This allows for a more controlled and predictable aging process.

Comparing and Contrasting Different Cheese Varieties

Different cheese varieties exhibit varying characteristics when vacuum sealed and aged. Understanding these differences helps in selecting the right cheese for your aging project.

- Cheddar: Cheddar is a popular choice for vacuum sealing and aging. It is a hard cheese with a relatively low moisture content, making it ideal for aging. As cheddar ages, it develops sharper flavors and a more crumbly texture. A young cheddar will become more complex, and an older cheddar will become even more flavorful. For example, a mild cheddar aged for 6 months in a vacuum-sealed bag will develop a more pronounced cheddar flavor, and potentially some crystal formation.

- Parmesan: Parmesan is a hard, granular cheese that benefits greatly from aging. Vacuum sealing helps to control moisture loss and allows the cheese to develop a complex, nutty flavor and a crystalline texture. The longer parmesan is aged, the more intense the flavor and the more pronounced the crystals. Consider a parmesan aged for 24 months, which develops a significantly more concentrated flavor profile than a parmesan aged for only 12 months.

- Gouda: Gouda is a semi-hard cheese that ages well when vacuum sealed. It has a slightly higher moisture content than cheddar or parmesan, but it still benefits from the controlled environment. As gouda ages, it develops a more complex, caramel-like flavor and a firmer texture. Younger gouda (e.g., 6 months) will become more flavorful, and older gouda (e.g., 18 months) will develop a more intense flavor and potentially some crystal formation.

Preparing Cheese for Vacuum Sealing

Before vacuum sealing your cheese for aging, meticulous preparation is crucial. This step ensures optimal results, promoting the development of desired flavors and textures while minimizing the risk of unwanted mold or bacterial growth. Proper preparation involves trimming, surface cleaning, and careful handling to create an environment conducive to successful aging.

Trimming and Surface Cleaning

The initial step in preparing cheese for vacuum sealing involves trimming and cleaning the surface. This process removes any unwanted elements and prepares the cheese for the aging process.Proper trimming and cleaning offer several benefits:

- Removes surface molds or blemishes: Eliminating these imperfections prevents them from spreading during aging.

- Ensures a clean surface for sealing: A clean surface allows for a better seal, reducing the risk of air leaks.

- Controls moisture: Surface moisture can encourage undesirable mold growth; cleaning helps to mitigate this.

Here’s how to trim and clean cheese:

- Trimming: Use a clean, sharp knife to trim away any rind, surface mold, or discolored areas. Be precise and remove only the unwanted parts, preserving as much of the edible cheese as possible. For hard cheeses, you may want to remove a thin layer of the surface. For soft cheeses, handle with care to avoid damaging the interior.

- Surface Cleaning: After trimming, clean the cheese surface. For hard cheeses, gently wipe the surface with a clean cloth dampened with a solution of food-grade vinegar and water (a ratio of 1:1 is often used). This helps to remove any remaining surface contaminants. For soft cheeses, a dry, clean cloth may suffice to gently remove surface moisture or debris. Ensure the cloth is clean to avoid introducing new contaminants.

- Drying: Allow the cheese to air dry completely after cleaning. This prevents excess moisture from being sealed in, which can promote mold growth. Place the cheese on a clean surface, such as a drying rack or a clean plate, in a cool, dry area.

Importance of Proper Handling and Sanitation

Maintaining proper sanitation and handling techniques is paramount throughout the entire process. This minimizes the risk of introducing unwanted bacteria or mold spores, which can ruin the cheese during aging.The following practices help maintain sanitation:

- Cleanliness: Thoroughly clean and sanitize all surfaces, utensils, and equipment that come into contact with the cheese. This includes cutting boards, knives, cloths, and the vacuum sealer.

- Hand Hygiene: Wash your hands thoroughly with soap and water before handling the cheese. Consider wearing food-safe gloves to further minimize contamination.

- Sterilization: Use a food-grade sanitizer, such as a solution of bleach and water (diluted according to manufacturer instructions), to sanitize all equipment. Rinse thoroughly with clean water after sanitizing.

- Separate Equipment: Dedicate specific equipment for cheese handling to avoid cross-contamination from other foods.

Temperature Considerations and Pre-Sealing Treatments

Temperature plays a crucial role in cheese preparation and aging. It influences both the cheese’s physical properties and the growth of microorganisms. Pre-sealing treatments can further enhance the aging process.Temperature management is essential:

- Cheese Temperature: Before vacuum sealing, ensure the cheese is at refrigerator temperature (around 4°C or 40°F). This helps to slow down microbial activity and prevents the cheese from becoming too soft during handling.

- Room Temperature: Work in a cool, clean environment. Avoid exposing the cheese to excessive heat or direct sunlight, which can degrade its quality.

Pre-sealing treatments to consider:

- Drying Time: As mentioned earlier, allow the cheese to dry completely after cleaning. This step removes excess moisture that could promote mold growth. The drying time depends on the type of cheese and the environmental conditions, but generally, a few hours in a cool, dry place is sufficient.

- Brining (for some cheeses): Some cheeses, such as certain types of cheddar, may benefit from a brief brine treatment before sealing. This can help to control surface mold and enhance flavor development. If using brine, ensure the cheese is thoroughly dried after the brining process.

Equipment and Materials Needed

Vacuum sealing cheese for aging requires specific equipment and materials to ensure proper preservation and achieve the desired results. Having the right tools and supplies is crucial for a successful aging process.

Essential Equipment and Materials

To effectively vacuum seal cheese for aging, several items are indispensable. These tools and materials contribute to the creation of an airtight environment, preventing spoilage and allowing the cheese to mature properly.

- Vacuum Sealer: This is the core piece of equipment, responsible for removing air from the packaging.

- Vacuum Sealer Bags or Rolls: These specialized bags or rolls are designed to withstand the vacuum sealing process and provide an airtight seal. Choose bags that are food-grade and BPA-free.

- Cheese: The type of cheese you select will determine the aging process and the flavor profiles that develop.

- Scale: A kitchen scale is helpful for measuring the weight of the cheese.

- Cutting Board: A clean cutting board is essential for preparing the cheese.

- Knife or Cheese Slicer: Used for cutting the cheese into manageable portions for sealing.

- Permanent Marker: For labeling the sealed bags with the cheese type and date.

- Labels: To clearly identify each cheese and the date it was sealed.

Types of Vacuum Sealers

There are two primary types of vacuum sealers: chamber sealers and external (or suction) sealers. The choice between these two types depends on factors such as budget, the volume of cheese being sealed, and the desired level of vacuum.

Pros and Cons of Vacuum Sealer Types

Understanding the advantages and disadvantages of each type of vacuum sealer helps in making an informed decision. This table provides a comparative overview:

| Feature | Chamber Sealer | External (Suction) Sealer |

|---|---|---|

| Vacuum Strength | Typically achieves a higher vacuum level, removing more air. | Vacuum level is generally lower compared to chamber sealers. |

| Bag Type | Works with standard and embossed bags. Can seal liquids effectively. | Requires embossed bags to allow air to escape. Not ideal for liquids. |

| Ease of Use | Simpler to use; the entire bag goes inside the chamber. | Requires more care in aligning the bag with the sealing strip. |

| Cost | Generally more expensive. | More affordable. |

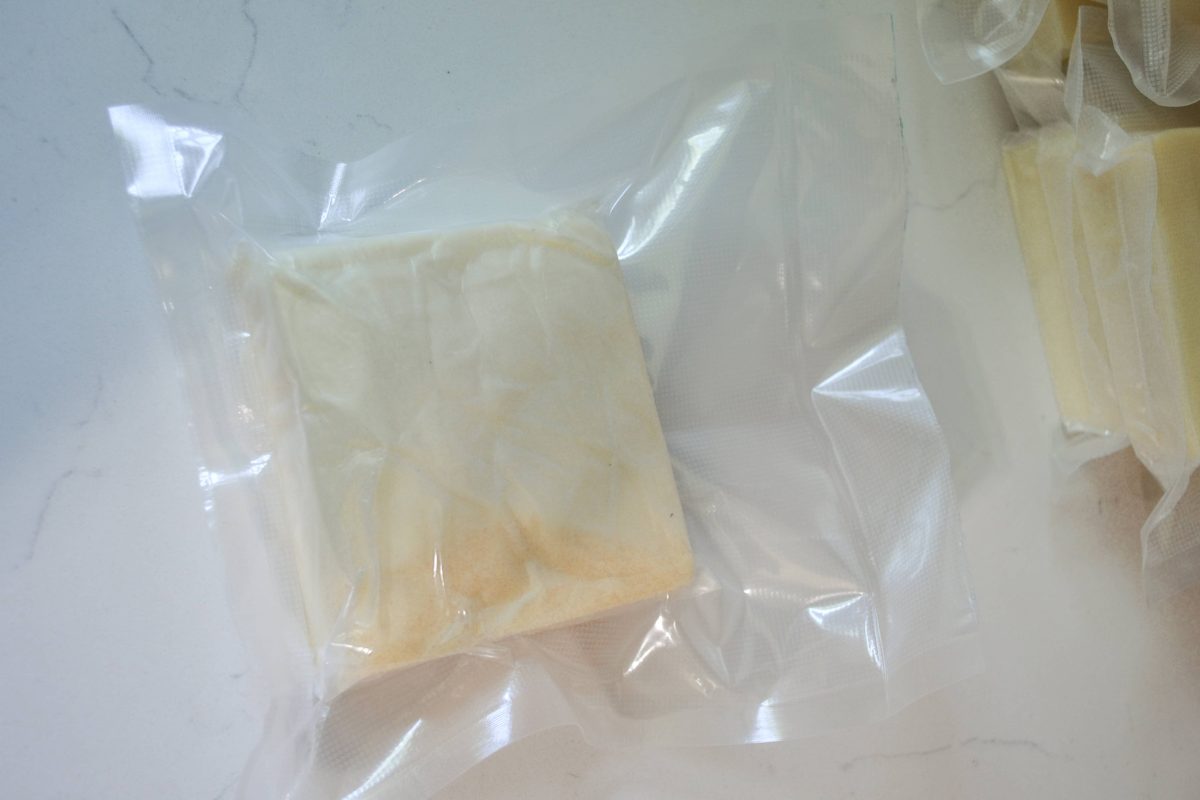

The Vacuum Sealing Process

Now that you have your cheese selected, prepared, and all the necessary equipment ready, it’s time to dive into the vacuum sealing process itself. This is where the magic happens, and proper technique is crucial for successful cheese aging. We’ll break down the steps, address common challenges, and ensure your cheese ages beautifully.

Bag Selection and Sealing Procedures

Choosing the right bags and mastering the sealing procedure are fundamental to the process. The bags need to be food-safe and designed for vacuum sealing.

- Bag Material: Opt for bags specifically designed for vacuum sealing, typically made of polyethylene or a combination of polyethylene and nylon. These materials offer a good barrier against oxygen and moisture. Avoid using regular plastic bags as they are not designed for vacuum sealing and can tear or leak.

- Bag Size: Select a bag size that is appropriate for the cheese you are sealing. The bag should be large enough to accommodate the cheese and allow for a good seal, but not so large that it wastes material or makes the sealing process difficult. Consider leaving about 2-3 inches of extra space at the top of the bag for sealing.

- Sealing Procedure: This involves several steps to ensure an airtight seal.

- Prepare the Bag: Place the cheese inside the bag, ensuring there is no cheese near the sealing area. Wipe the sealing area clean and dry.

- Position the Bag: Place the open end of the bag inside the vacuum sealer, following the manufacturer’s instructions.

- Vacuum and Seal: Activate the vacuum sealer. The machine will remove the air from the bag and then seal it. Most sealers have an automatic mode, but some may require manual sealing.

- Check the Seal: Once sealed, inspect the seal for any gaps or imperfections. If there are any, you can reseal the bag, or cut the bag open and start again with a fresh seal.

Sealing Different Cheese Shapes and Sizes

Different cheese shapes and sizes require slightly different approaches to ensure a successful vacuum seal. The goal is to maximize contact between the cheese and the bag while preventing damage.

- Hard Cheeses (e.g., Cheddar, Parmesan):

- Blocks: For rectangular blocks, ensure the corners of the cheese are not sharp enough to puncture the bag. If necessary, trim any sharp edges. Place the cheese in the bag, leaving enough space for sealing. Seal according to the procedures mentioned above.

- Wheels: For whole or partial wheels, consider using a slightly larger bag. Ensure the wheel is positioned so that the vacuum process does not deform the cheese.

- Soft Cheeses (e.g., Brie, Camembert):

- Delicate Handling: Soft cheeses are more fragile. Handle them carefully to avoid damage. Consider placing the cheese on a small piece of parchment paper or a cutting board before placing it in the bag to prevent it from sticking or deforming during the sealing process.

- Gentle Vacuuming: Use the “seal only” function or the “pulse” feature on your vacuum sealer to control the vacuuming process and prevent crushing the cheese.

- Crumbly Cheeses (e.g., Feta, Blue Cheese):

- Gentle Handling: These cheeses can crumble easily. Consider placing the cheese in a bag with minimal vacuum pressure.

- Pre-Portioning: Pre-portion the cheese into smaller portions before sealing to reduce the amount of air trapped and make the aging process more consistent.

Avoiding Common Pitfalls During Vacuum Sealing

Several issues can arise during vacuum sealing. Knowing how to prevent them can save you from wasted cheese and frustration.

- Cheese Damage:

- Sharp Edges: Ensure cheese edges are not sharp. If they are, trim them to avoid bag punctures.

- Excessive Vacuum Pressure: Use the “seal only” or “pulse” function for soft cheeses to prevent crushing.

- Bag Failure:

- Punctures: Ensure the cheese does not have sharp edges or pieces that can puncture the bag. Check the bag for any pre-existing damage.

- Poor Seal: Ensure the sealing area is clean and dry. Check the sealer’s settings to make sure it’s sealing properly. Sometimes, the bag might not be compatible with the sealer.

- Air Leaks:

- Improper Seal: Ensure the seal is even and complete. If necessary, reseal the bag.

- Bag Material: Use high-quality vacuum sealing bags designed for food storage.

- Moisture in the Seal:

- Drying: Dry the cheese surface and the bag’s sealing area to ensure a good seal. Moisture can prevent the bag from sealing correctly.

Aging Cheese in a Vacuum Seal

Now that your cheese is safely sealed, it’s time to focus on the aging process itself. This is where the magic happens, transforming the cheese’s flavor and texture over time. Understanding the ideal environment and monitoring the changes is key to success.

Ideal Environmental Conditions for Aging Vacuum-Sealed Cheese

Creating the right environment is crucial for successful aging. The goal is to slow down the aging process and allow the cheese to develop its desired characteristics without excessive mold growth or undesirable changes.To achieve optimal aging, two main factors need careful management:

- Temperature: A consistent, cool temperature is essential. The ideal temperature range for aging most cheeses in a vacuum seal is between 38-45°F (3-7°C). This range slows down the enzymatic activity responsible for flavor development and textural changes. Temperatures significantly higher than this can lead to accelerated aging and potential spoilage, while temperatures lower can stall the aging process completely.

- Humidity: While the vacuum seal minimizes the impact of humidity, a slightly humid environment can still be beneficial. Aim for a relative humidity of around 75-85%. This helps prevent the cheese from drying out excessively during the aging period. You can achieve this by storing the sealed cheese in a dedicated cheese cave, a refrigerator with a crisper drawer (which often has higher humidity), or even a regular refrigerator with a container of water nearby.

Timeline for Aging Different Cheese Varieties

The aging time varies greatly depending on the cheese type. Harder cheeses generally require longer aging periods than softer cheeses. The flavor and texture changes are also unique to each variety.

Here are some examples of aging timelines for different cheese types:

- Cheddar: Cheddar cheese can be aged for several months to several years.

- Young Cheddar (2-6 months): This cheddar will have a milder flavor and a relatively smooth texture.

- Mature Cheddar (6-12 months): The flavor will intensify, becoming sharper and more complex, with a slightly firmer texture.

- Aged Cheddar (1-2+ years): Expect a very sharp, intense flavor and a firm, sometimes crystalline texture.

- Parmesan: Parmesan is a hard cheese that benefits from extended aging.

- Young Parmesan (12-18 months): The cheese will be firm, with a slightly salty and nutty flavor.

- Aged Parmesan (24+ months): The flavor will be intensely savory, with a granular texture and crystalline structures.

- Gouda: Gouda’s aging timeline depends on the desired intensity of flavor.

- Young Gouda (1-6 months): Mild, buttery flavor with a smooth texture.

- Mature Gouda (6-12 months): Flavor becomes more pronounced with caramel notes and a slightly firmer texture.

- Aged Gouda (12+ months): Intense flavor, sometimes with a slightly crumbly texture and crystalline formations.

- Blue Cheese: Blue cheese is typically aged for a shorter period.

- Young Blue Cheese (1-3 months): Milder blue flavor and a creamy texture.

- Mature Blue Cheese (3-6 months): More intense blue flavor and a creamier texture.

Tips for Monitoring the Aging Process

Regular monitoring is essential to ensure the cheese is aging properly and to catch any potential issues early.

Here’s how to monitor your vacuum-sealed cheese:

- Visual Inspection:

- Mold: Check for any unusual mold growth inside the vacuum seal. While some mold is normal in cheese aging, excessive or colored mold (e.g., black, pink, or green) can indicate spoilage. If you see undesirable mold, discard the cheese.

- Changes in Appearance: Note any changes in the cheese’s color, texture, or shape. If the cheese is bulging or leaking liquid, it could indicate spoilage and should be discarded.

- Sensory Evaluation:

- Smell: Carefully smell the cheese. A pleasant, cheesy aroma is a good sign. Any off-putting smells, such as ammonia or a strong, unpleasant odor, may indicate spoilage.

- Touch: Gently press on the cheese to assess its texture. The cheese should be firming up. A slimy or overly soft texture could indicate a problem.

- Taste: After the initial aging period, sample a small piece of the cheese. The flavor should be developing as expected for the cheese variety. If the flavor is undesirable, the cheese might be spoiled or the aging conditions might need adjustment.

- Record Keeping:

- Keep a log of your observations, including the date, cheese type, visual appearance, smell, texture, and taste. This will help you track the aging progress and identify any trends or issues.

Troubleshooting Common Issues

Aging cheese in a vacuum seal, while generally successful, isn’t without its potential pitfalls. Understanding and addressing these issues is crucial for achieving the desired flavor and texture profile. This section will explore common problems that may arise during the aging process and offer solutions to ensure your cheese ages beautifully.

Mold Growth on Cheese During Aging

Mold is the most frequent issue encountered when aging cheese. While some molds are beneficial and contribute to flavor development (like those found on bloomy rind cheeses), unwanted mold can spoil the cheese and create off-flavors. The type of mold, the extent of its growth, and the cheese’s characteristics influence the severity of the problem.

- Cause: Improper vacuum sealing, which can leave residual oxygen, allows mold spores to thrive. High humidity inside the bag can also contribute to mold growth. Cheese with surface moisture before sealing is another culprit.

- Prevention: Ensure a proper vacuum seal. Inspect the sealing bar for any damage. Thoroughly dry the cheese surface before sealing. Store the sealed cheese in a cool, consistent temperature environment, ideally between 40-55°F (4-13°C). Monitor the cheese periodically for any signs of mold growth.

- Correction: If you notice a small amount of mold on the cheese’s surface, you might be able to salvage it. Carefully cut away the moldy area, ensuring you remove at least 1 inch of cheese around the affected area to prevent the spread of mold spores. Reseal the cheese. If the mold is widespread or appears to be penetrating deep into the cheese, it is best to discard it.

Off-Flavors Developing in Aged Cheese

Off-flavors can ruin the taste of your aged cheese. These undesirable tastes can range from bitter or ammonia-like to metallic or soapy. Several factors can contribute to the development of these unwanted flavors.

- Cause: Bacterial contamination, inadequate aging conditions (temperature or humidity fluctuations), or the use of improper ingredients can lead to off-flavors. The breakdown of proteins and fats during aging, if not carefully managed, can also result in unpleasant tastes.

- Prevention: Use high-quality cheese and ingredients. Maintain consistent temperature and humidity levels throughout the aging process. Ensure the cheese is stored in a clean environment. Consider using cheese with a proven track record for aging well.

- Correction: Once off-flavors develop, there is often little that can be done to correct them. The cheese may be salvageable if the off-flavor is very mild. Try to cut away the affected portion. In most cases, the cheese is best discarded.

Problems with Cheese Texture During Aging

The texture of cheese is a critical aspect of its quality. Problems during aging can lead to undesirable changes in texture, such as excessive dryness, a rubbery consistency, or a mushy interior.

- Cause: Excessive drying due to improper humidity control or inadequate sealing. Temperature fluctuations can also affect the texture, leading to undesirable changes. Incorrect cheese selection for vacuum aging, such as a very soft cheese, might result in textural problems.

- Prevention: Maintain proper humidity levels during aging. Ensure a tight vacuum seal. Choose cheeses that are known to age well. Monitor the cheese’s texture regularly.

- Correction: If the cheese is drying out, try re-sealing it with a new vacuum bag. If the cheese is too dry, you might not be able to recover the initial texture. In the case of a rubbery texture, the cheese might be over-aged. If the texture is mushy, the cheese might have been stored at too high a temperature or not properly vacuum-sealed.

Post-Aging Handling and Storage

After the cheese has aged to your desired level of maturity, the next steps are crucial to preserving its quality and ensuring the best possible eating experience. This section focuses on how to handle, store, cut, and serve your aged cheese, maximizing its flavor and enjoyment.

Removing Cheese from the Vacuum Seal

Carefully remove the cheese from the vacuum seal. The cheese might have developed a slight aroma, which is normal and a sign of the aging process.

Cheese Storage After Opening

Once the cheese is out of the vacuum seal, proper storage is essential to prevent it from drying out or developing unwanted molds.

- Wrap the cheese: Use cheese paper, wax paper, or parchment paper to wrap the cheese. These materials allow the cheese to breathe while still providing a barrier against the air.

- Storage location: Store the wrapped cheese in the refrigerator, ideally in the cheese drawer or a crisper drawer, where the humidity is higher.

- Avoid plastic wrap: While plastic wrap can be used, it tends to trap moisture, which can lead to mold growth. If using plastic wrap, replace it frequently.

- Temperature: Maintain a refrigerator temperature between 35-45°F (2-7°C) for optimal storage.

- Check regularly: Check the cheese periodically for any signs of mold or spoilage. If mold appears, trim it off (if it’s a surface mold) or discard the cheese if it’s pervasive.

Cutting and Serving Aged Cheese

The way you cut and serve aged cheese significantly impacts the eating experience. Different cheeses require different approaches.

- Tools: Use a sharp cheese knife, a cheese slicer, or a cheese plane. The right tool for the job makes cutting easier and cleaner.

- Wedge-shaped cheeses: For wedge-shaped cheeses, cut from the tip towards the rind. This allows everyone to sample all parts of the cheese.

- Round cheeses: For round cheeses, cut wedges from the center, leaving a portion of the rind on each piece.

- Hard cheeses: Use a cheese knife with a pointed tip to break off pieces or slice thinly.

- Soft cheeses: Use a soft cheese knife or a thin, non-serrated knife to prevent the cheese from sticking and tearing.

- Serving temperature: Allow the cheese to come to room temperature (about 30-60 minutes) before serving to enhance its flavors and aromas.

Pairing Aged Cheese

Pairing aged cheese with suitable beverages and accompaniments elevates the tasting experience.

A Comprehensive Guide to Cheese Pairings

Hard Cheeses (e.g., Cheddar, Gruyère, Parmesan):

- Beverages: Full-bodied red wines (Cabernet Sauvignon, Merlot), strong ales, dry sherry.

- Accompaniments: Crusty bread, fruit preserves (fig, apricot), nuts (walnuts, almonds), honey.

Semi-Hard Cheeses (e.g., Gouda, Havarti):

- Beverages: Medium-bodied red wines (Pinot Noir), amber ales, crisp white wines (Sauvignon Blanc).

- Accompaniments: Crackers, grapes, apples, pears, chutney.

Soft Cheeses (e.g., Brie, Camembert):

- Beverages: Sparkling wine (Champagne, Prosecco), light-bodied red wines (Beaujolais), dry white wines (Chardonnay).

- Accompaniments: Baguette, crackers, fresh berries, honey, nuts.

Blue Cheeses (e.g., Gorgonzola, Roquefort):

- Beverages: Sweet dessert wines (Sauternes), port wine, strong stouts.

- Accompaniments: Crackers, honey, dried fruits (figs, dates), walnuts.

Closing Notes

In summary, mastering How to Vacuum Seal Cheese for Aging is a rewarding endeavor that opens up a world of possibilities for cheese lovers. From selecting the perfect cheese to monitoring its transformation in the vacuum seal, this guide provides all the necessary steps. With the right techniques and a little patience, you can enjoy artisanal cheeses at home, expanding your culinary horizons and savoring the delicious results of your aging efforts.