Embark on a journey into the art of cheese preservation with “How to Wax a Wheel of Hard Cheese for Long-Term Storage.” This guide transforms the seemingly complex task of waxing cheese into an approachable and rewarding experience. Discover how this age-old technique not only extends the shelf life of your favorite hard cheeses but also enhances their flavor profiles over time, offering a taste of tradition and culinary craftsmanship.

Waxing hard cheese is a superior method compared to simply refrigerating, as it creates a protective barrier that seals in moisture, prevents mold growth, and allows the cheese to breathe and age gracefully. Learn which hard cheeses benefit most from this method, from aged cheddars and goudas to parmesans and beyond. This guide will provide all the knowledge and techniques needed to ensure your cheese remains delicious for months to come.

The Importance of Waxing Hard Cheese

Waxing hard cheese is a time-honored technique that significantly extends its shelf life and preserves its quality. This process creates a protective barrier that prevents unwanted mold growth, moisture loss, and flavor deterioration, allowing you to enjoy your favorite cheeses for months, even years, to come.Compared to simply refrigerating hard cheese, waxing offers superior protection. Refrigeration alone can dry out the cheese, leading to cracking and a loss of flavor and texture.

Waxing, however, creates an airtight seal, maintaining the cheese’s optimal moisture content and preventing the entry of spoilage organisms. This method allows the cheese to age gracefully, developing complex flavors over time.

Cheeses Best Suited for Waxing

Certain types of hard cheeses benefit most from waxing due to their lower moisture content and dense texture. Waxing is particularly effective for cheeses that are intended to be aged for extended periods.

- Cheddar: Cheddar cheese, especially aged cheddar, is an excellent candidate for waxing. The wax coating helps maintain the cheese’s moisture and prevents it from drying out during the aging process, allowing the flavors to intensify. For example, a well-waxed cheddar can age gracefully for a year or more, developing a sharper, more complex flavor profile.

- Gouda: Gouda, known for its smooth texture and nutty flavor, also benefits greatly from waxing. The wax coating protects the cheese from mold and helps retain its moisture, ensuring a creamy texture as it ages. A typical aged Gouda, properly waxed, can be stored for up to 18 months, developing a richer flavor.

- Parmesan (Parmigiano-Reggiano): This hard, granular cheese is traditionally waxed to protect it during its long aging process. Waxing helps to prevent the cheese from drying out and cracking, preserving its complex flavors and texture. The wax coating also acts as a barrier against unwanted mold growth. Parmesan cheeses are often aged for 12 months or more, and the wax helps them maintain their quality during this time.

- Swiss: Swiss cheese, with its distinctive holes and slightly sweet flavor, can also be successfully waxed. The wax coating protects the cheese from environmental factors, helping to maintain its moisture content and preventing mold growth. Waxing allows the cheese to age properly and develop its characteristic flavor profile.

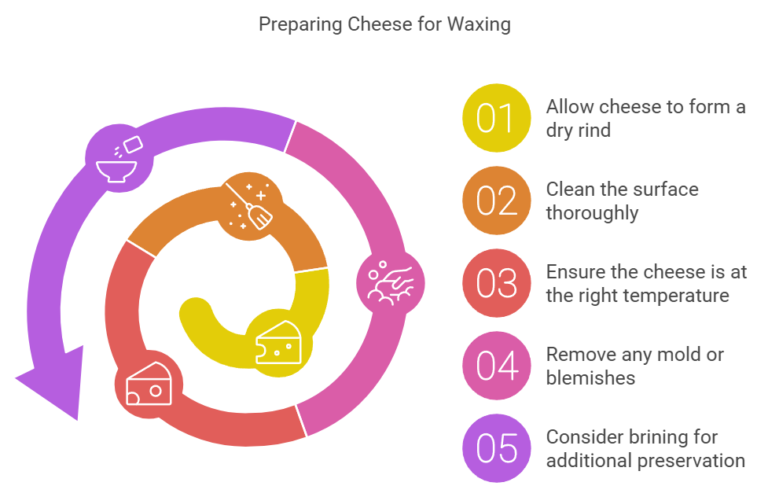

Preparing the Cheese for Waxing

Before you can encase your beautiful wheel of hard cheese in wax, you need to ensure it’s properly prepared. This stage is crucial for the long-term preservation and enjoyment of your cheese. Skipping these steps can lead to mold growth, uneven waxing, and ultimately, a disappointing cheese experience. The goal is to create a clean, dry surface that allows the wax to adhere properly, forming a protective barrier against the environment.

Ideal Cheese Condition Before Waxing

The ideal condition of the cheese is paramount to successful waxing. This stage is all about ensuring the cheese is ready to receive its protective coating.The cheese should be at the correct age. The aging process will determine the cheese’s flavor profile and texture. Hard cheeses, such as cheddar, gouda, or parmesan, typically need to have aged for a certain period.

For example, a cheddar may be aged for several months, or even years, depending on the desired flavor. The cheese’s age will influence its moisture content and surface characteristics.The surface moisture of the cheese must be considered. The surface of the cheese should be dry to the touch. Excess moisture will prevent the wax from adhering correctly, creating air pockets and providing an environment for mold growth.

A slightly moist surface, especially in a cheese that has been recently handled, is a signal to take extra care in drying.

Cleaning and Drying the Cheese Surface

Cleaning and drying the cheese surface is a delicate but essential task. It removes any surface contaminants and prepares the cheese for the wax. This process ensures the wax adheres properly, creating a protective seal.Here are the tools you’ll need:

- Clean, Food-Grade Brush: A soft-bristled brush is ideal for gently removing any surface mold or debris. Make sure it is dedicated solely to cheese preparation.

- Clean, Dry Cloths or Paper Towels: Use lint-free cloths or paper towels for drying the cheese.

- White Vinegar (Optional): A diluted white vinegar solution (1 part vinegar to 10 parts water) can be used to sanitize the cheese surface, especially if mold is present.

- Clean Work Surface: A clean, flat surface is essential for this process. Consider using a food-safe cutting board or clean countertop.

Here are the steps to follow:

- Inspect the Cheese: Examine the entire surface of the cheese for any visible mold, cracks, or imperfections. If you notice mold, gently brush it off. If the cheese has any deep cracks, these should be addressed, potentially by trimming the affected area, before waxing.

- Clean the Surface (Optional): If you choose to use vinegar, lightly dampen a clean cloth with the diluted solution and gently wipe the entire surface of the cheese. Be careful not to over-saturate the cheese.

- Dry the Cheese: Using a clean, dry cloth or paper towel, gently pat the entire surface of the cheese to remove any moisture. Pay close attention to crevices and uneven areas. The cheese surface should be completely dry to the touch.

- Allow to Air Dry (Optional): For added assurance, you can allow the cheese to air dry for a short period, typically 30 minutes to an hour, in a cool, dry place. This will ensure any remaining surface moisture evaporates.

Cheese Preparation Checklist

This checklist summarizes the cheese preparation process, including estimated time for each step. This will help to ensure the process is consistent and to avoid common errors.

| Step | Description | Estimated Time |

|---|---|---|

| Inspect the Cheese | Visually examine the cheese for mold, cracks, and imperfections. | 2-5 minutes |

| Clean the Surface (Optional) | Gently wipe the cheese surface with a diluted white vinegar solution (if desired). | 2-3 minutes |

| Dry the Cheese | Pat the entire cheese surface dry with clean cloths or paper towels. | 5-10 minutes |

| Allow to Air Dry (Optional) | Leave the cheese to air dry in a cool, dry place. | 30-60 minutes |

“Proper cheese preparation is the foundation for successful waxing and long-term cheese storage.”

Materials Needed

To successfully wax a wheel of hard cheese, you’ll need to gather the right materials and tools. This ensures a smooth process and a well-protected cheese that will last for an extended period. Having everything ready before you begin will save time and effort.

Different Types of Cheese Wax

Several types of wax are suitable for cheese waxing, each with its own characteristics. Understanding the properties of each type allows you to choose the best option for your specific needs.Wax options include:

- Paraffin Wax: This is a widely used and cost-effective option. It’s derived from petroleum and provides a good barrier against air and moisture.

- Soy Wax Blends: Soy wax blends are a more environmentally friendly alternative. They are often mixed with other waxes to improve their properties, such as melting point and adhesion.

- Beeswax: Beeswax offers a natural and food-safe option. It has a pleasant aroma and can add a subtle flavor to the cheese. However, it tends to be more expensive and may not be as durable as other options.

- Paraffin-Soy Wax Blends: Combining paraffin and soy wax offers a balance of cost-effectiveness, environmental friendliness, and performance.

Tools and Equipment Required for Waxing

Proper tools are essential for achieving a professional-looking and effective wax coating on your cheese. A well-equipped workspace will make the process easier and more enjoyable.You will need the following tools and equipment:

- Wax Melter or Double Boiler Setup: This is used to safely melt the wax. A wax melter provides precise temperature control, while a double boiler setup (a pot of water with a heat-safe bowl on top) can also be used.

- Thermometer: A thermometer is crucial for monitoring the wax temperature. This ensures that the wax is hot enough to melt properly but not so hot that it burns or degrades.

- Waxing Pot: A pot specifically for melting wax is needed. It’s best to dedicate a pot solely for this purpose.

- Cheese Wheel Holder: This device allows for easier handling and dipping of the cheese wheel into the wax.

- Tongs or Dipping Tools: Tongs or specialized dipping tools are useful for safely maneuvering the cheese wheel in the hot wax.

- Paper Towels or Rags: These are used for cleaning up spills and wiping the cheese before and after waxing.

- Heat-Resistant Gloves: Heat-resistant gloves protect your hands from burns.

- Cutting Board: A cutting board to prepare the cheese for waxing.

- Scale: A scale to weigh the cheese and wax.

Comparing Different Wax Types

The properties of different waxes vary significantly. The table below compares key characteristics to help you choose the best wax for your needs.

| Wax Type | Melting Point (°C) | Adhesion | Flexibility |

|---|---|---|---|

| Paraffin Wax | 52-63 | Good | Brittle |

| Soy Wax Blends | 49-60 | Good | More Flexible |

| Beeswax | 62-65 | Good | Flexible |

| Paraffin-Soy Wax Blends | 50-62 | Excellent | Balanced |

Melting the Wax and Temperature Control

Now that you’ve gathered your cheese and supplies, the next crucial step is safely melting the wax and maintaining the correct temperature. This process is vital for creating a durable, protective coating that preserves your cheese. Improper melting or temperature control can lead to a compromised wax seal, potentially affecting the cheese’s flavor and longevity.

Safely Melting the Wax

Melting cheese wax requires careful attention to prevent burns and ensure the wax functions as intended. This involves choosing the right equipment and following safety protocols.

Here’s a guide to safely melting your cheese wax:

- Choose Your Melting Method: There are a few safe ways to melt cheese wax. The double boiler method is highly recommended. This involves placing the wax in a heat-safe container (like a stainless steel pot) and placing that container inside a larger pot of simmering water. The steam from the water gently heats the wax, preventing direct exposure to a heat source that could cause it to burn or ignite.

Alternatively, you can use an electric wax melter designed for this purpose. Avoid using a microwave, as uneven heating can occur, and the wax can easily overheat.

- Prepare Your Workspace: Set up your workspace in a well-ventilated area. Place a heat-resistant surface (like a trivet or cutting board) under your wax melting setup to protect your countertop. Have your safety equipment readily available (oven mitts, a fire extinguisher or a container of sand, and first-aid supplies).

- Monitor the Wax: As the wax melts, monitor it closely. Stir it gently and frequently to ensure even melting. Never leave the melting wax unattended.

- Avoid Direct Heat: Never apply direct heat to the wax, unless you’re using an electric wax melter specifically designed for that purpose. Direct heat can cause the wax to ignite, creating a fire hazard.

- Never Add Water: Avoid adding water to the wax, as this can cause splattering and potential burns.

Optimal Wax Temperature for Dipping

The temperature of the melted wax is critical for successful cheese waxing. The correct temperature ensures the wax adheres properly to the cheese and forms a protective seal without damaging the cheese itself.

The ideal temperature range for dipping cheese is typically between 240°F and 260°F (115°C – 127°C). This temperature range allows the wax to:

- Adhere Properly: At this temperature, the wax is fluid enough to coat the cheese evenly and adhere effectively to its surface.

- Prevent Cheese Damage: This temperature is hot enough to melt the wax but not so hot that it will damage the cheese or cause it to melt.

- Form a Protective Seal: The wax, when cooled, forms a solid barrier against air and moisture, preserving the cheese.

To accurately monitor the wax temperature, use a dedicated candy thermometer or a digital thermometer with a clip to secure it to the side of your melting container. Regularly check the temperature throughout the melting and dipping process.

Safety Guide for Handling Hot Wax

Handling hot wax poses potential hazards. Following safety precautions and knowing how to respond to accidents is essential.

Here’s a safety guide to minimize risks:

- Protective Gear: Always wear appropriate personal protective equipment (PPE). This includes:

- Oven mitts or heat-resistant gloves: To protect your hands from burns.

- Eye protection: Safety glasses or a face shield to protect your eyes from splashes.

- Long sleeves and an apron: To protect your skin from accidental wax spills.

- Workspace Setup:

- Stable Surface: Place the wax melting setup on a stable, heat-resistant surface, away from flammable materials.

- Well-Ventilated Area: Work in a well-ventilated area to avoid inhaling wax fumes.

- Fire Safety: Keep a fire extinguisher or a container of sand nearby, in case of a fire. Never use water to extinguish a wax fire; this can spread the flames.

- Handling Hot Wax:

- Gentle Stirring: Stir the wax gently and slowly to prevent splattering.

- Careful Pouring: When pouring wax, do so slowly and deliberately.

- Avoid Distractions: Pay close attention to the task at hand and avoid distractions.

- First-Aid:

- For Minor Burns: Immediately cool the burn under cool running water for 10-20 minutes. Do not use ice. Cover the burn with a clean, dry dressing.

- For Severe Burns: Seek immediate medical attention. Call emergency services.

- Eye Contact: If wax gets into your eyes, flush them with cool water for at least 15 minutes and seek medical attention.

Dipping the Cheese

Now that your wax is at the correct temperature, and your cheese is prepared, it’s time for the exciting part: dipping! This step requires a steady hand and a bit of patience, but the results are well worth the effort. Properly waxing your cheese creates an airtight seal, preserving its flavor and texture for months, or even years, to come.

The Waxing Procedure, Step-by-Step

The dipping process involves submerging the cheese in the melted wax, allowing it to cool, and repeating the process to build up a protective layer. Here’s how to do it effectively:

- Prepare your workspace: Ensure your work surface is clean and covered with a disposable material like newspaper or butcher paper. Have your cheese, melted wax, a long-handled spoon or ladle, and a thermometer readily available.

- Gently lower the cheese: Carefully grasp the cheese, ideally using the cheese itself (if the shape allows) or with a pair of tongs, and slowly submerge it into the melted wax. Avoid splashing the wax.

- Maintain even submersion: Hold the cheese submerged for a few seconds, allowing the wax to fully coat the surface. Rotate the cheese gently to ensure an even coating.

- Remove and drain: Slowly lift the cheese out of the wax. Allow the excess wax to drip back into the pot.

- Cool and repeat: Place the waxed cheese on your prepared surface to cool and harden. After the first layer has hardened (usually within a minute or two), repeat the dipping process. Aim for at least two to three coats of wax, allowing each layer to cool and harden before applying the next.

- Inspect and address imperfections: Once the final coat has hardened, inspect the cheese for any imperfections, such as thin spots or air bubbles. You can often address these by spot-dipping the affected areas with a small amount of wax.

Achieving an Even Wax Coating

Achieving an even wax coating is crucial for effective cheese preservation. Several factors can affect the outcome.

- Temperature Control: Maintaining the correct wax temperature is critical. If the wax is too hot, it can damage the cheese and create an uneven coating. If it’s too cool, the wax may not adhere properly. Refer to the recommended temperature range for your specific wax type.

- Air Bubbles: Air bubbles trapped under the wax can compromise the seal. To minimize air bubbles, dip the cheese slowly and steadily, avoiding any sudden movements. If air bubbles appear, you can often pop them with a toothpick or a clean needle while the wax is still warm.

- Uneven Dipping: Ensure the cheese is fully submerged during each dip. Rotate the cheese gently to coat all sides evenly. If the cheese has an irregular shape, you might need to use a spoon or ladle to ensure all areas are covered.

- Wax Thickness: The wax layer should be thick enough to provide a good seal, but not excessively thick. A layer of about 1/8 inch (3 mm) is usually sufficient. Multiple thinner coats are preferable to one thick coat.

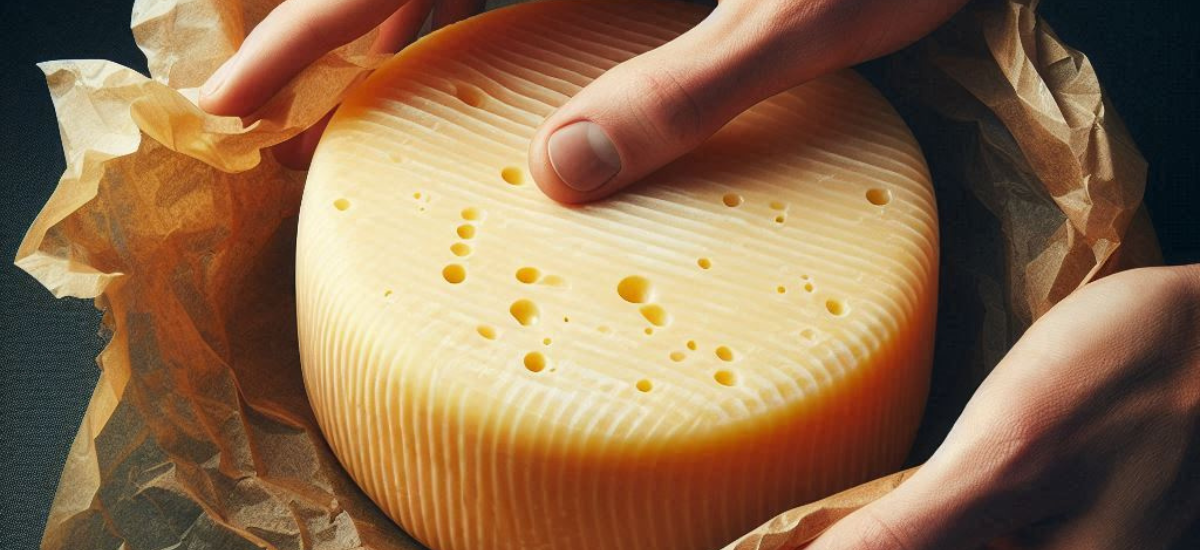

Visual Guide: Hand and Cheese Positioning

This visual guide illustrates the correct hand and cheese positioning during the dipping process.

Image Description:

A series of three illustrations depict the waxing process. The first shows a person holding a wheel of cheese with one hand, positioned at the top of the cheese, and gently lowering it into a pot of melted wax. The wax level is clearly visible, and the cheese is being submerged slowly. The person’s other hand is free.The second illustration shows the cheese fully submerged in the wax. The hand holding the cheese is now resting at the side, allowing the wax to completely cover the top. The person is holding the cheese steady, ensuring no air bubbles are trapped.

The third illustration shows the cheese being lifted out of the wax.The person is lifting it slowly, allowing excess wax to drip back into the pot. The hand is still holding the cheese securely, and the wax coating is visible.

Multiple Coats and Drying

Applying multiple coats of wax is crucial for creating a robust and effective seal that protects your hard cheese from the environment and promotes long-term storage. This process ensures a complete barrier against mold, bacteria, and moisture, extending the cheese’s shelf life and preserving its flavor and texture.

Rationale for Multiple Coats

The primary purpose of multiple coats is to build up a thicker, more durable protective layer. This redundancy provides several key benefits for cheese preservation:

- Enhanced Protection: Each coat of wax adds to the overall thickness of the barrier, making it more resistant to physical damage, such as scratches or impacts, that could compromise the seal.

- Improved Seal: Multiple coats help to fill in any tiny imperfections or pinholes that may have formed during the initial dipping process. These imperfections, if left unaddressed, could provide entry points for unwanted organisms.

- Extended Shelf Life: A thicker, more complete seal significantly extends the cheese’s shelf life by minimizing moisture loss and preventing the growth of mold and other spoilage agents.

- Even Coating: Multiple coats allow for a more even distribution of the wax, ensuring consistent protection across the entire surface of the cheese.

Time Between Coats and Drying Process

The timing and drying conditions are critical for achieving a successful wax coating. Proper drying allows each layer to fully solidify, creating a strong bond between the coats.

The recommended time between coats is typically around 30 minutes to 1 hour. This allows the wax to cool and harden, providing a solid base for the next coat. The exact time may vary depending on the ambient temperature and humidity.

Ideal drying conditions involve a cool, dry environment. A temperature of around 60-70°F (15-21°C) and a relative humidity of 50-60% are optimal. Avoid direct sunlight or drafts, as these can cause uneven cooling and potentially cracking of the wax.

Here’s the general process:

- First Coat: Dip the cheese in the melted wax and allow it to drain and cool for the recommended time.

- Drying: Place the cheese on a clean surface, away from direct sunlight and drafts, to dry completely.

- Subsequent Coats: Repeat the dipping and drying process for at least two more coats, or as needed, depending on the cheese and desired level of protection.

Troubleshooting Common Problems

Even with careful execution, issues can arise during the multiple-coat process. Knowing how to address these problems will help you achieve a successful and protective wax coating.

- Uneven Coats: This can result from inconsistent dipping, wax temperature variations, or uneven cooling. To address this, ensure the cheese is fully submerged in the wax, maintain a consistent wax temperature, and avoid drafts during cooling.

- Wax Cracking: Cracking often occurs if the wax cools too quickly or if the cheese is moved before the wax is fully set. To prevent cracking, ensure the cheese is allowed to cool slowly and evenly in a draft-free environment. You may also consider using a wax blend with a slightly lower melting point.

- Wax Peeling: If the wax is peeling away from the cheese, it could be due to insufficient cleaning of the cheese surface before waxing or an improper wax-to-cheese bond. Make sure the cheese is completely dry and clean before waxing. Consider roughening the cheese surface slightly with a clean cloth to promote better adhesion.

- Air Bubbles: Trapped air bubbles can create weak spots in the wax. To minimize air bubbles, dip the cheese slowly and carefully, and avoid any rapid movements.

Storage After Waxing

Now that your cheese is beautifully waxed, the next crucial step is proper storage. This ensures your hard cheese ages gracefully, developing complex flavors and textures over time. The environment in which you store your waxed cheese significantly impacts its final quality.

Ideal Storage Conditions

The ideal storage environment for waxed hard cheese involves maintaining a balance of temperature and humidity. These factors work together to control the aging process and prevent unwanted mold growth or excessive drying.* Temperature: Aim for a consistent temperature between 50-55°F (10-13°C). This range slows down the ripening process, allowing the cheese to develop flavor gradually. A cooler temperature will slow ripening even further, while a warmer temperature will accelerate it.

Consider a dedicated cheese cave or a wine refrigerator if possible, as these provide more stable temperature control than a standard refrigerator.

Humidity

Maintain a humidity level between 75-85%. This prevents the cheese from drying out and cracking, which can compromise the wax seal and allow mold to develop. You can achieve this in several ways: use a dedicated cheese fridge, or a regular refrigerator with a humidity control system.

Air Circulation

While not as critical as temperature and humidity, good air circulation is beneficial. This helps prevent the build-up of moisture and potential mold growth. Avoid storing the cheese in a completely sealed container.

Monitoring the Cheese During Storage

Regular monitoring is essential to ensure your waxed cheese is aging properly and to identify any potential problems early on.* Visual Inspection: Regularly inspect the wax coating for any cracks, bulges, or signs of mold. A small crack can allow air to penetrate, leading to mold growth under the wax. Bulging might indicate gas production inside the cheese, potentially due to bacterial activity.

Mold on the wax is usually harmless, but any mold under the wax needs to be addressed immediately.

Aroma Check

Periodically smell the cheese. A pleasant, cheesy aroma is a good sign. Any off-odors, such as ammonia or a strong, unpleasant smell, could indicate spoilage.

Touch Test

Gently feel the cheese. It should remain firm and slightly pliable. If the cheese feels excessively soft or mushy, it could indicate spoilage.

Weight Check

Weigh the cheese periodically. Significant weight loss suggests the cheese is drying out, which can affect its texture.

Do’s and Don’ts for Storing Waxed Cheese

Here’s a concise guide to ensure your waxed cheese ages beautifully:* Do’s:

- Store the cheese in a cool, humid environment.

- Monitor the cheese regularly for any signs of spoilage.

- Clean any mold that appears on the wax with a clean cloth dampened with a food-safe solution like vinegar or a diluted alcohol solution.

- Consider turning the cheese occasionally to ensure even aging.

- If a crack appears in the wax, you can re-wax the affected area.

* Don’ts:

- Store the cheese in a warm, dry environment.

- Ignore any signs of spoilage.

- Allow the cheese to dry out or crack.

- Store the cheese near strong-smelling foods. Cheese can absorb odors from its surroundings.

- Refrigerate in the main compartment without checking humidity and temperature.

Ending Remarks

In conclusion, mastering the art of waxing a wheel of hard cheese opens up a world of possibilities for cheese lovers. By following the steps Artikeld in this guide, from preparing the cheese and selecting the right wax to the dipping process and proper storage, you can confidently preserve your favorite cheeses, ensuring they are ready to enjoy whenever the craving strikes.

Embrace this time-honored practice and savor the delicious rewards of your efforts.