Embark on a journey into the fascinating world of cheesemaking, where the seemingly simple choice of milk holds the key to unlocking a symphony of flavors and textures. This guide, “How to Choose the Best Milk for Cheesemaking,” delves deep into the intricacies of milk selection, revealing how different types, compositions, and processing methods can dramatically impact your cheese creations.

From understanding the nuances of cow breeds to mastering the art of milk evaluation, you’ll gain the knowledge to transform ordinary milk into extraordinary cheese.

We’ll explore the influence of fat, protein, and casein levels, and how pasteurization and homogenization play a role. You’ll learn about the benefits and risks of raw milk, the impact of seasonal variations, and the importance of pH and acidity. Get ready to discover the secrets of cream separation, fat adjustment, and heat treatment, along with best practices for milk storage.

Finally, we’ll guide you through sourcing milk, comparing organic and conventional options, and matching milk to specific cheese styles, ensuring your cheesemaking endeavors are a resounding success.

Milk Types and Their Suitability for Cheesemaking

Choosing the right milk is the first and arguably most crucial step in cheesemaking. The type of milk significantly influences the final cheese’s flavor, texture, and overall characteristics. Understanding the differences between milk sources and how they are processed will empower you to make informed decisions and achieve the best results in your cheesemaking endeavors.

Cow Milk Breeds and Cheese Characteristics

Different breeds of cows produce milk with varying compositions, directly impacting the cheese they yield. These differences in fat, protein, and other components result in distinct cheese profiles.For example:

- Jersey Cows: Jersey milk is known for its high fat and protein content compared to other breeds. This richness contributes to a creamier, more flavorful cheese with a higher yield. Cheeses made with Jersey milk often have a richer mouthfeel and a more pronounced flavor profile. They are often preferred for making butter and aged cheeses.

- Holstein Cows: Holstein milk is generally lower in fat and protein than Jersey milk, though still suitable for cheesemaking. Cheeses made from Holstein milk may be less rich in flavor and yield compared to Jersey milk cheeses. Holstein milk is widely used in commercial cheesemaking due to its higher milk production volume.

- Guernsey Cows: Guernsey milk is also high in fat and protein, similar to Jersey milk, often resulting in a cheese with a golden hue and a rich, buttery flavor. The milk’s high beta-carotene content contributes to the color.

The choice of cow breed, therefore, has a significant impact on the characteristics of the cheese produced. Cheesemakers often select breeds based on the desired characteristics of their final product.

Comparison of Milk Types: Fat, Protein, and Casein

The composition of milk varies significantly between different animal species. These variations in fat, protein, and casein levels directly influence the cheese-making process and the resulting cheese characteristics.Here’s a comparison of the approximate fat, protein, and casein content in cow, goat, and sheep milk:

| Milk Type | Fat Content (%) | Protein Content (%) | Casein Content (%) |

|---|---|---|---|

| Cow Milk | 3.25 – 4.0 | 3.0 – 3.5 | 2.4 – 2.8 |

| Goat Milk | 3.5 – 4.5 | 3.0 – 3.6 | 2.2 – 2.6 |

| Sheep Milk | 5.0 – 8.0 | 5.0 – 6.0 | 4.0 – 5.0 |

- Fat Content: Sheep milk has the highest fat content, leading to richer, creamier cheeses. Cow milk has a moderate fat content, while goat milk is slightly higher than cow milk.

- Protein Content: Sheep milk also has the highest protein content, contributing to a firmer curd and higher cheese yield. Cow and goat milk have similar protein levels.

- Casein Content: Casein is the primary protein responsible for curd formation. Sheep milk has the highest casein content, followed by cow milk, and then goat milk. Higher casein levels typically result in a firmer cheese.

These differences in composition explain why cheeses made from different milk types have distinct textures, flavors, and aging characteristics.

Impact of Pasteurization and Homogenization on Cheesemaking

The processes of pasteurization and homogenization, commonly applied to milk, significantly impact its suitability for cheesemaking. Understanding these effects is essential for achieving the desired cheese characteristics.

- Pasteurization: Pasteurization involves heating milk to a specific temperature for a set duration to kill harmful bacteria. While it ensures food safety, it can also alter the milk’s protein structure.

- Effect: Pasteurization can weaken the milk’s ability to coagulate, potentially leading to a softer curd. It also reduces the natural enzymes present in raw milk, which contribute to flavor development during aging.

- Mitigation: Cheesemakers often add calcium chloride to pasteurized milk to improve coagulation and may use a starter culture with specific enzymes to compensate for the loss of natural enzymes.

- Homogenization: Homogenization breaks down fat globules into smaller particles, preventing them from separating and rising to the surface.

- Effect: Homogenization makes the milk more stable, but it can also interfere with the cheesemaking process. It can reduce the curd’s ability to trap fat, leading to a less creamy cheese and potential fat loss in the whey.

- Mitigation: Some cheesemakers avoid using homogenized milk or adjust their cheesemaking techniques to compensate for the changes in fat distribution.

The choice between pasteurized and unpasteurized milk, as well as homogenized and unhomogenized milk, is a crucial decision that significantly influences the final cheese characteristics.

Role of Raw Milk in Cheese Production

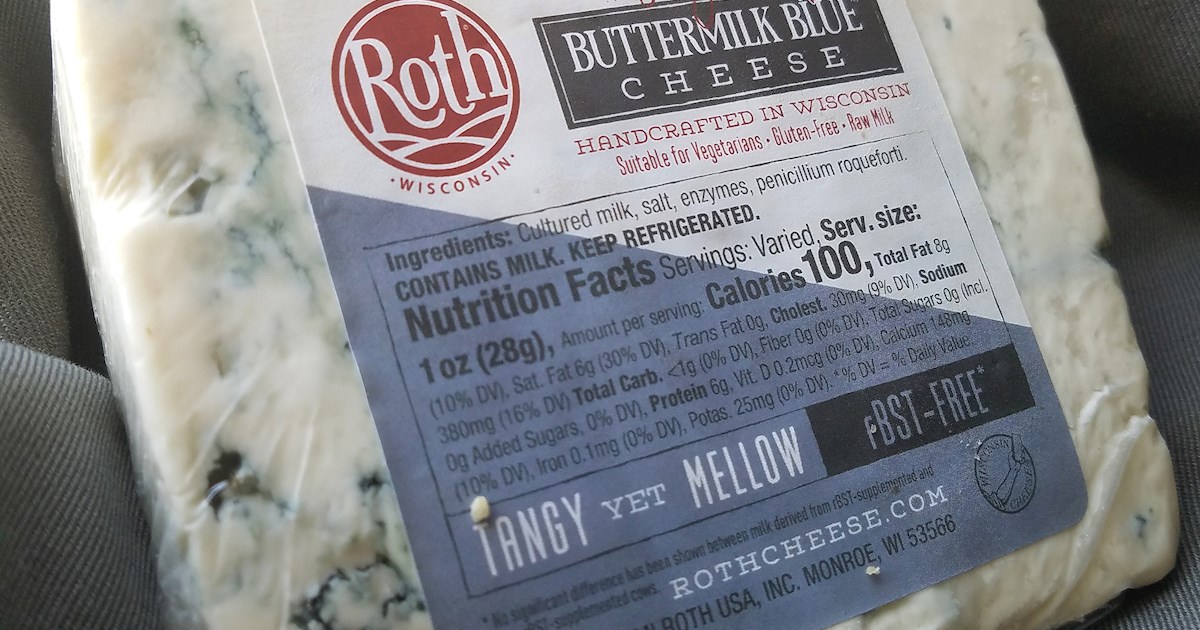

Raw milk, which has not been pasteurized, is often favored by artisan cheesemakers due to its unique characteristics. However, it also presents certain risks that must be carefully considered.

- Benefits:

- Enhanced Flavor: Raw milk contains a wider range of natural enzymes and bacteria that contribute to complex flavors during the aging process.

- Improved Texture: The intact proteins and fats in raw milk can result in a more complex texture and a more pronounced mouthfeel in the cheese.

- Unique Microbial Profile: Raw milk carries a diverse microbial community, which can contribute to the development of unique and regional cheese characteristics.

- Risks:

- Pathogen Presence: Raw milk may contain harmful bacteria, such as

-Listeria*,

-Salmonella*, and

-E. coli*, that can cause foodborne illnesses. - Stringent Regulations: The production and sale of raw milk cheeses are subject to strict regulations in many countries to ensure food safety.

- Pathogen Presence: Raw milk may contain harmful bacteria, such as

Cheesemakers who use raw milk must adhere to rigorous sanitation practices and implement stringent quality control measures to mitigate the risks associated with pathogens. The aging process itself often helps to reduce the presence of harmful bacteria, but it is not a guarantee of safety. The decision to use raw milk in cheesemaking involves a careful balance of potential benefits and inherent risks.

Milk Composition and its Influence on Cheese

The composition of milk is the foundation upon which all cheese is built. Understanding the key components and how they interact is crucial for predicting and controlling the final characteristics of your cheese. The proportions of fat, protein, lactose, and minerals dictate everything from the cheese’s texture and flavor to its aging properties. This section will delve into the intricacies of milk’s composition and its profound impact on cheesemaking.

Key Components of Milk and Their Contribution to Cheese

Milk is a complex fluid, and each component plays a vital role in cheesemaking. Let’s examine these key components and their specific contributions.

- Fat: Contributes significantly to the flavor, texture, and mouthfeel of cheese. Higher fat content generally results in a richer, creamier cheese. Fat also carries flavor compounds, enhancing the overall taste experience.

- For example, a brie cheese made with high-fat milk will have a smoother, more decadent texture and a more pronounced flavor compared to a brie made with low-fat milk.

- Protein (Casein and Whey): Casein proteins are the primary building blocks of cheese, forming the curd structure. Whey proteins, while less abundant, contribute to the cheese’s moisture content and can influence texture.

- Casein is responsible for the solid structure of cheese. The higher the casein content, the firmer the curd will be.

- Lactose (Milk Sugar): Lactose is converted into lactic acid by bacteria during cheesemaking. This acid plays a crucial role in curd formation, flavor development, and preservation.

- The amount of lactose present will influence the final acidity of the cheese, which is a key factor in determining its flavor profile.

- Minerals (Calcium, Phosphates): Minerals contribute to the structure and stability of the cheese curd. Calcium, in particular, is essential for the formation of the casein network.

- Calcium and phosphates help to create a more stable curd structure, influencing the cheese’s ability to retain moisture and its overall texture.

Casein Protein Types and Their Impact on Cheesemaking

Casein proteins exist in several forms, each with a unique impact on the cheesemaking process. The three main types are alpha, beta, and kappa-casein. Their ratios and properties influence curd formation, texture, and the cheese’s overall characteristics.

- Alpha-Casein: This casein type is sensitive to calcium and is responsible for forming the initial curd structure. It helps create the network that traps fat and moisture.

- Higher levels of alpha-casein can lead to a firmer curd.

- Beta-Casein: Beta-casein contributes to the elasticity and softness of the cheese. It also plays a role in the breakdown of proteins during ripening, influencing flavor development.

- Beta-casein is more sensitive to proteolysis (protein breakdown) during aging, contributing to the development of complex flavors and textures.

- Kappa-Casein: Kappa-casein stabilizes the casein micelles (tiny protein structures) in milk, preventing them from clumping together. It is cleaved by rennet, initiating the coagulation process.

- Rennet’s action on kappa-casein is what allows the milk to coagulate and form a curd. Without kappa-casein, the milk would not coagulate properly.

Seasonal Variations in Milk Composition and Cheese Quality

The composition of milk is not static; it varies throughout the year due to factors such as the cow’s diet, stage of lactation, and environmental conditions. These seasonal changes can significantly affect cheese quality.

- Fat Content: Fat content tends to be higher in the autumn and winter months when cows are often fed more concentrated feed. This can lead to richer, more flavorful cheeses during these seasons.

- Cheesemakers often adjust their recipes to account for these fluctuations. For instance, they might reduce the rennet amount during winter months when fat content is higher.

- Protein Content: Protein levels can also fluctuate, influencing curd firmness and yield. Higher protein content generally leads to a firmer curd and a higher cheese yield.

- During spring, when cows graze on fresh pasture, milk protein levels often increase, resulting in a more robust cheese.

- Lactose Content: Lactose levels can vary slightly, impacting the rate of acid production by bacteria and the overall flavor profile.

- Changes in lactose levels can influence the final acidity of the cheese, which can affect its texture and flavor.

Ideal Milk pH and Acidity Levels for Different Cheese Styles

The pH and acidity of milk and the resulting cheese are critical parameters that influence flavor, texture, and preservation. Different cheese styles require specific pH ranges for optimal development.

- Fresh Cheeses (e.g., Cottage Cheese, Ricotta): These cheeses typically have a higher final pH (around 5.0-5.3). The acidity is lower, resulting in a fresh, mild flavor.

- The lower acidity preserves the fresh, milky flavor profile.

- Soft-Ripened Cheeses (e.g., Brie, Camembert): These cheeses are allowed to ripen from the outside in. The pH gradually decreases as the cheese ripens. The final pH is usually around 4.6-4.8.

- The higher pH promotes the growth of surface molds, contributing to the cheese’s characteristic flavors and textures.

- Hard Cheeses (e.g., Cheddar, Parmesan): Hard cheeses undergo a more extended aging process, and the pH gradually decreases. The final pH can range from 5.0 to 5.3, depending on the cheese style.

- The lower pH helps preserve the cheese and contributes to its sharp, complex flavors.

- Acid Development Measurement: The acid development in milk can be measured using a variety of methods. The most common is the use of a pH meter.

The pH of milk decreases as lactic acid is produced, so monitoring the pH is critical during the cheesemaking process.

Evaluating Milk Quality for Cheesemaking

Before embarking on the cheesemaking process, it’s crucial to assess the quality of your milk. The quality of the milk directly impacts the final cheese’s flavor, texture, yield, and shelf life. This section Artikels methods for evaluating milk quality, including sensory analysis, laboratory tests, and considerations for spoilage indicators.

Assessing Milk Freshness

Evaluating milk freshness involves several methods, from simple sensory checks to more sophisticated laboratory analyses. These assessments help determine if the milk is suitable for cheesemaking.

- Sensory Evaluation: This involves using your senses to evaluate the milk. It’s a quick and accessible way to detect potential problems.

- Appearance: Fresh milk should have a uniform, slightly opaque appearance. Look for any signs of clumping, discoloration (e.g., yellowing or a bluish tinge), or sediment.

- Smell: Fresh milk has a mild, slightly sweet odor. Off-odors like sourness, rancidity, or a barny smell indicate spoilage.

- Taste: Fresh milk should have a pleasant, slightly sweet taste. Avoid tasting raw milk if you are not sure of its origin and handling. Off-flavors like bitterness, sourness, or metallic tastes are indicators of poor quality.

- Texture: Fresh milk should have a smooth, slightly viscous texture. Any changes in texture, such as thickening, curdling, or a grainy feel, can indicate spoilage or contamination.

- Laboratory Tests: These tests provide more objective and quantitative measures of milk quality.

- Titratable Acidity (TA): Measures the lactic acid content in milk. As milk ages, bacteria convert lactose into lactic acid, increasing the TA. A higher TA indicates spoilage.

- pH: Measures the acidity or alkalinity of the milk. Fresh milk typically has a pH of around 6.6-6.8. A lower pH indicates increased acidity and potential spoilage.

- Bacterial Counts: Determine the number of bacteria present in the milk. High bacterial counts suggest poor hygiene and potential spoilage.

- Fat Content: Measures the fat percentage in the milk, which influences cheese yield and texture.

- Protein Content: Measures the protein percentage in the milk, crucial for cheese coagulation and structure.

Indicators of Milk Spoilage and Their Effects

Milk spoilage can significantly impact cheesemaking outcomes. Identifying the indicators of spoilage helps prevent the production of low-quality cheese.

- Sourness: Caused by the growth of lactic acid bacteria. Sour milk produces cheese with an overly acidic taste and a crumbly texture.

- Rancidity: Results from the breakdown of milk fats, often due to enzymatic activity. Rancid milk produces cheese with an unpleasant, soapy flavor.

- Off-Flavors: These can be caused by various factors, including bacterial growth, feed-related issues, or contamination. The cheese will have an undesirable flavor, which may mask the natural flavor of the cheese.

- Clotting: Indicates advanced spoilage, often due to bacterial action or enzymatic activity. The cheese will have a curdled appearance and a poor texture.

- Reduced Yield: Spoilage can degrade milk proteins, leading to a lower cheese yield.

- Poor Texture: Spoiled milk often results in cheese with an undesirable texture, such as being too soft, crumbly, or grainy.

The Importance of Somatic Cell Count (SCC)

The somatic cell count (SCC) measures the number of somatic cells (primarily white blood cells) present in milk. A high SCC indicates inflammation in the cow’s udder, often caused by mastitis. This has significant implications for cheesemaking.

- Reduced Cheese Yield: High SCC milk contains altered proteins that can negatively affect cheese coagulation, resulting in a lower yield. For instance, a study by the University of Wisconsin-Madison found that milk with an SCC above 400,000 cells/mL resulted in a 5-10% reduction in cheese yield compared to milk with an SCC below 200,000 cells/mL.

- Altered Cheese Texture: High SCC milk can produce cheese with a softer, more crumbly texture. This is due to the breakdown of casein proteins by enzymes released by the somatic cells.

- Changes in Cheese Flavor: High SCC milk can contribute to off-flavors in cheese. The breakdown of fats and proteins by enzymes can result in bitter or soapy tastes.

- Increased Whey Protein: High SCC can lead to increased levels of whey proteins, affecting the moisture content and structure of the cheese.

Step-by-Step Milk Coagulation Test

Performing a simple milk coagulation test can help assess the milk’s ability to form a curd, a critical step in cheesemaking.

- Materials:

- Milk sample

- Rennet (liquid or tablet)

- Warm water (about 95°F or 35°C)

- Small container or test tube

- Thermometer

- Timer

- Procedure:

- Warm the milk sample to the recommended temperature for your chosen rennet type (typically around 86-90°F or 30-32°C).

- Prepare the rennet solution according to the manufacturer’s instructions. If using liquid rennet, add the recommended amount to a small amount of warm water. If using rennet tablets, dissolve the tablet in warm water.

- Add the rennet solution to the milk sample.

- Gently stir the milk for about 30 seconds to ensure even distribution of the rennet.

- Cover the container and allow the milk to sit undisturbed.

- Monitor the milk for coagulation. This usually takes between 30-60 minutes, depending on the milk quality and rennet strength.

- Check for a clean break. This is when the curd is firm enough to cut with a knife or spatula and a clear whey separates from the curd.

- Interpretation:

- If the milk coagulates quickly and forms a firm curd, the milk is likely of good quality.

- If the milk takes a long time to coagulate, or if the curd is weak or crumbly, the milk quality may be compromised. This could indicate low protein content, high SCC, or other issues.

Processing Milk for Cheesemaking

Processing milk correctly is crucial for achieving consistent cheese quality and the desired characteristics. These processes influence the final product’s texture, flavor, and shelf life. Understanding and applying these techniques allows cheesemakers to control the cheesemaking process effectively.

Cream Separation and Its Effect on Cheese Fat Content

Cream separation is a mechanical process used to divide milk into two components: cream (which is rich in fat) and skim milk (which has a very low fat content). This process allows cheesemakers to adjust the fat content of the milk used for cheesemaking, directly impacting the final cheese product.The most common method involves using a cream separator. This device spins milk at high speeds, utilizing centrifugal force to separate the lighter cream from the heavier skim milk.

The speed of the separator and the design of the equipment influence the efficiency of the separation.The effect of cream separation on cheese fat content is significant. By removing some of the cream, cheesemakers can reduce the overall fat content of the cheese. Conversely, adding cream back to the milk increases the fat content. This control is critical because fat contributes to the cheese’s flavor, texture, and melting properties.

For instance:* Higher Fat Content: Typically results in a richer flavor, a smoother texture, and improved melting characteristics. Cheeses like Brie and Camembert, known for their creamy texture, often have a higher fat content.

Lower Fat Content

Leads to a firmer texture and a milder flavor. Examples include some varieties of Feta and cottage cheese.The specific fat content desired depends on the cheese type being made and the cheesemaker’s preferences.

Methods for Adjusting Milk Fat Content

Adjusting the milk fat content is a critical step in cheesemaking, allowing for precise control over the final cheese characteristics. Several methods are employed to achieve the desired fat levels, influencing the cheese’s flavor, texture, and overall quality.One common method involves cream separation, as described above. The cheesemaker separates the milk into cream and skim milk, then recombines them in specific ratios to achieve the target fat content.

This method provides the greatest flexibility.Another approach involves adding cream directly to the milk. This is particularly useful when the milk is initially too low in fat. The amount of cream added is calculated based on the initial milk fat content and the desired final fat content.Cheesemakers also sometimes use skim milk powder to reduce the fat content. Skim milk powder is added to the milk, increasing the solids-not-fat content without increasing the fat content.

This can affect the texture and body of the cheese.The following formula can be used to calculate the required amount of cream to add to a given quantity of milk:

C = (M

- (Fd

- F i)) / (F c

- F i)

Where:* C = Amount of cream to add

- M = Amount of milk

- F d = Desired fat percentage in the final milk

- F i = Initial fat percentage in the milk

- F c = Fat percentage in the cream

For example, if you have 100 liters of milk with 3.5% fat (F i), and you want to increase the fat content to 4.5% (F d) using cream with 35% fat (F c), the calculation would be: C = (100

(4.5 – 3.5)) / (35 – 3.5) = 2.94 liters of cream.

Accurate measurement of fat content is essential for these calculations. Cheesemakers typically use a Babcock test or a similar method to determine the fat percentage in the milk and cream.

Procedure for Heat-Treating Milk

Heat-treating milk is a fundamental step in cheesemaking, primarily employed to eliminate or significantly reduce harmful microorganisms, and to inactivate enzymes that could negatively impact the cheese’s quality and shelf life. The specific heat treatment method used depends on the type of cheese being made.* Pasteurization: This is the most common heat treatment method. Milk is heated to a specific temperature for a set duration, which is sufficient to kill most pathogenic bacteria while minimizing changes to the milk’s flavor and nutritional properties.

There are different pasteurization methods:

Low-Temperature Long-Time (LTLT) Pasteurization

Milk is heated to 63°C (145°F) for 30 minutes. This method is less common now, but can still be used for some cheese types.

High-Temperature Short-Time (HTST) Pasteurization

Milk is heated to 72°C (161°F) for 15 seconds. This is the most widely used method for commercial cheesemaking, offering a good balance between pathogen reduction and minimal flavor impact.

Thermization

This is a milder heat treatment, typically involving heating milk to 57-68°C (135-154°F) for a short period (15-30 seconds). It reduces the number of spoilage organisms and inactivates some enzymes but doesn’t completely eliminate all bacteria. Thermization is often used for cheeses that require some beneficial bacteria to survive.

Ultra-High Temperature (UHT) Treatment

Milk is heated to a very high temperature, typically 135-150°C (275-302°F) for a few seconds. This process sterilizes the milk, eliminating almost all microorganisms. UHT milk is not typically used for cheesemaking, as it significantly alters the milk proteins and can affect cheese making properties.The choice of heat treatment method depends on the cheese type. For example, some soft cheeses, such as Brie, may benefit from a lower heat treatment to preserve the flavor and activity of beneficial bacteria.

Hard cheeses, on the other hand, may use HTST pasteurization to ensure a safe product.After heat treatment, the milk must be cooled rapidly to the ideal temperature for the addition of starter cultures and rennet. The cooling process helps to prevent the growth of undesirable microorganisms and ensures that the cheesemaking process proceeds as planned.

Best Practices for Storing and Handling Milk

Proper storage and handling of milk are essential to maintaining its quality and ensuring the success of the cheesemaking process. Adhering to these best practices helps to prevent spoilage, preserve the milk’s flavor, and minimize the risk of foodborne illnesses.* Temperature Control: Milk should be stored at a cold temperature immediately after collection or pasteurization. Ideally, store raw milk at 4°C (40°F) or below.

Pasteurized milk should also be stored at 4°C (40°F) or below to slow bacterial growth.

Cleanliness

All equipment and containers used to store and handle milk should be thoroughly cleaned and sanitized. This includes storage tanks, pipelines, and any other surfaces that come into contact with the milk.

Preventing Contamination

Milk should be protected from contamination from other sources, such as cleaning chemicals, dust, and insects. Ensure that storage areas are clean and well-ventilated.

Proper Containers

Use food-grade containers made of stainless steel or plastic. Avoid using containers that can react with the milk or impart off-flavors.

Minimizing Exposure to Air

Keep milk containers tightly sealed to reduce exposure to air, which can promote oxidation and spoilage.

Rotation

Use the “first in, first out” (FIFO) method for milk storage. This ensures that the oldest milk is used first, reducing the risk of spoilage.

Monitoring Quality

Regularly monitor the milk’s quality by checking its temperature, appearance, and smell. Any signs of spoilage, such as off-odors, discoloration, or curdling, should be investigated immediately.

Rapid Cooling After Pasteurization

After pasteurization, milk should be cooled down as quickly as possible to the ideal temperature for cheesemaking. This minimizes the risk of bacterial growth.

Testing Raw Milk

If using raw milk, regularly test it for bacteria count and somatic cell count. This ensures the milk is suitable for cheesemaking and free from pathogens.

Milk Sourcing and Availability

Choosing the right milk source is a critical step in cheesemaking, impacting both the final product’s quality and the overall cheesemaking process. This section delves into the considerations for sourcing milk, comparing different options, and evaluating potential suppliers. Understanding milk availability in your region is also essential for successful cheesemaking.

Factors to Consider When Choosing a Milk Source

Selecting a milk source requires careful consideration of several factors to ensure the best possible outcome for your cheese. These factors directly influence the cheese’s flavor, texture, and overall quality.

- Milk Freshness: Fresh milk is crucial for cheesemaking. The shorter the time between milking and cheesemaking, the better. This minimizes bacterial growth and enzymatic changes that can negatively affect the cheese.

- Milk Composition: The fat and protein content of the milk significantly impact the cheese’s characteristics. Higher fat content generally results in richer, creamier cheeses, while protein content affects the cheese’s structure and ability to hold moisture. Understanding the milk’s composition allows you to adjust your cheesemaking process accordingly.

- Milk Handling Practices: The way the milk is handled from the farm to your cheesemaking facility is important. Proper cooling, storage, and transportation are essential to maintain milk quality. Milk should be cooled to 4°C (40°F) or below as quickly as possible after milking to inhibit bacterial growth.

- Milk Source Reputation: Research the milk source’s reputation. Inquire about their animal welfare practices, hygiene standards, and commitment to quality. A reliable supplier is one that consistently delivers high-quality milk.

- Testing and Analysis: Regular milk testing for factors like somatic cell count, bacteria count, fat content, and protein content provides valuable data for process control and quality assurance. Milk testing can also detect the presence of antibiotics or other undesirable substances.

- Price and Availability: Consider the cost of the milk and the consistency of its supply. Ensure the milk source can meet your production needs throughout the year. Seasonal variations in milk production can impact availability and price.

- Proximity: Sourcing milk locally can reduce transportation costs and environmental impact. Local sources often offer fresher milk and a closer relationship with the supplier, which can facilitate communication and problem-solving.

Advantages and Disadvantages of Organic vs. Conventional Milk for Cheesemaking

The choice between organic and conventional milk can significantly affect the flavor, nutritional profile, and cost of your cheese. Each type of milk has its own set of advantages and disadvantages.

- Organic Milk Advantages:

- Animal Welfare: Organic dairy farms adhere to strict standards for animal welfare, including access to pasture and a diet free of genetically modified organisms (GMOs).

- Reduced Pesticide Exposure: Organic milk comes from cows that are not exposed to synthetic pesticides, herbicides, or fertilizers.

- Potential Nutritional Benefits: Some studies suggest that organic milk may have higher levels of beneficial fatty acids, such as omega-3s, although the differences are often small.

- Flavor Profile: Many cheesemakers and consumers perceive a more complex and nuanced flavor profile in cheese made from organic milk, potentially due to the cows’ diet.

- Organic Milk Disadvantages:

- Cost: Organic milk is typically more expensive than conventional milk, increasing the cost of production.

- Availability: Organic milk can be less readily available than conventional milk, especially in certain regions.

- Seasonal Variations: The composition of organic milk can vary depending on the season and the availability of pasture for grazing.

- Limited Antibiotic Use: The strict regulations regarding antibiotic use in organic farming can, in some cases, increase the risk of animal health problems, which could indirectly affect milk quality.

- Conventional Milk Advantages:

- Cost-Effectiveness: Conventional milk is generally less expensive than organic milk, making it a more economical option for cheesemakers.

- Availability: Conventional milk is widely available in most regions, ensuring a consistent supply.

- Consistent Composition: Milk from large conventional dairies often has a more consistent composition due to standardized feeding practices and breed selection.

- Conventional Milk Disadvantages:

- Animal Welfare Concerns: Conventional dairy farms may not always adhere to the same high standards of animal welfare as organic farms.

- Pesticide and Herbicide Exposure: Cows on conventional farms may be exposed to pesticides and herbicides through their feed.

- Antibiotic Use: Conventional dairy farms may use antibiotics to treat sick animals, potentially impacting milk quality if not handled correctly.

Availability of Different Milk Types in Various Regions

The availability of different milk types varies considerably depending on the region, influenced by factors such as climate, agricultural practices, and consumer demand.

- Cow’s Milk: Cow’s milk is the most widely available type of milk globally. However, availability can differ by region. In areas with intensive dairy farming, cow’s milk is generally abundant. In regions with less dairy infrastructure, sourcing can be more challenging. The availability of organic and specific breed milk (e.g., Jersey, Guernsey) often depends on local farm practices and consumer demand.

- Goat’s Milk: Goat’s milk availability is generally lower than cow’s milk, but it’s gaining popularity. Goat farming is more common in certain areas, such as the Mediterranean, parts of Asia, and the American Southwest. Availability can be seasonal, with peak production during the spring and summer months. The availability of fresh goat’s milk for cheesemaking may be limited to specific farms or local markets.

- Sheep’s Milk: Sheep’s milk is less common than cow’s or goat’s milk. It’s primarily available in regions with sheep farming, such as the Mediterranean, parts of Europe, and certain areas of the United States. Availability is often seasonal, with peak production in the spring. Sheep’s milk is often used for making specialty cheeses.

- Buffalo Milk: Buffalo milk is popular in certain parts of the world, particularly in South Asia and the Mediterranean. It is used to make specific cheeses, such as mozzarella. Availability is localized to regions where buffalo farming is prevalent.

- Raw Milk vs. Pasteurized Milk: The availability of raw milk for cheesemaking is subject to legal restrictions, which vary widely by location. Some regions allow raw milk sales, while others restrict or prohibit them. Pasteurization is a common process, and pasteurized milk is generally more readily available than raw milk.

Questionnaire to Evaluate a Milk Supplier’s Suitability for Cheesemaking Purposes

A comprehensive questionnaire can help assess a potential milk supplier’s suitability for cheesemaking. This questionnaire should cover various aspects of milk production and handling to ensure the milk meets the specific requirements of the cheesemaking process.

Supplier Information:

- Supplier Name and Contact Information

- Farm Location

- Type of Dairy Operation (e.g., family farm, commercial dairy)

Milk Production Practices:

- What breed(s) of cows do you have? (If applicable)

- How are the animals housed and cared for? (Describe housing conditions, access to pasture, and animal welfare practices.)

- What is the animals’ diet? (Specify feed composition, including whether it is organic, and if any GMOs are used.)

- What are your animal health management practices? (Detail the use of antibiotics, hormones, and other medications.)

- How often are the animals milked?

- What are your milking hygiene practices? (Describe cleaning and sanitization procedures for milking equipment.)

- Do you have any certifications (e.g., organic, animal welfare)?

Milk Handling and Storage:

- How quickly is the milk cooled after milking?

- What is the cooling temperature?

- How is the milk stored? (Describe storage tanks, materials, and cleaning procedures.)

- How is the milk transported? (Describe transportation methods, temperature control, and time to delivery.)

- How often do you test your milk? (Specify tests performed, such as fat, protein, somatic cell count, bacteria count, and antibiotic residue.)

- Do you provide milk testing results?

Milk Composition and Quality:

- What is the average fat percentage of your milk?

- What is the average protein percentage of your milk?

- What is the somatic cell count of your milk? (Ideal SCC is below 200,000 cells/mL)

- What is the bacteria count of your milk? (Indicate whether the counts are within acceptable standards.)

- Is your milk tested for antibiotic residues?

- Do you guarantee your milk to be free from antibiotics?

Supply and Pricing:

- What is your milk production capacity?

- Can you meet our anticipated milk needs?

- What is the pricing structure for your milk?

- Are there any seasonal variations in price or availability?

- What is your delivery schedule?

- What are your payment terms?

Additional Information:

- Are you willing to provide references from other customers?

- Are you open to discussing specific requirements or modifications to your practices?

- Is there anything else we should know about your operation?

Specific Cheese Styles and Milk Selection

Choosing the right milk is paramount for achieving the desired flavor, texture, and overall quality of your cheese. Different cheese styles benefit from specific milk types due to variations in fat content, protein composition, and other components that influence the cheesemaking process. This section explores the ideal milk choices for several popular cheese varieties, providing insights into how milk selection impacts the final product.

Mozzarella Cheese and Ideal Milk Type

The best milk for making mozzarella cheese is typically whole milk, ideally from a cow. This is because mozzarella requires a high protein content and a good balance of fat to achieve its characteristic stretch and melt.

Cheddar Cheese and Best Milk Choices

Cheddar cheese production benefits from a variety of milk options, each contributing unique flavor profiles and textures.

- Whole Cow’s Milk: This is a common choice, providing a good balance of fat and protein for a well-rounded cheddar flavor. The fat content contributes to a creamy texture and helps develop the complex flavors during aging.

- Raw Cow’s Milk: Many cheesemakers prefer raw milk for cheddar. Raw milk contains a wider range of beneficial bacteria and enzymes that contribute to a more complex and nuanced flavor development during the aging process. However, raw milk cheesemaking requires strict hygiene practices and adherence to food safety regulations.

- Milk Blends: Some cheesemakers experiment with blending different milk types, such as cow’s milk with a small percentage of sheep’s milk, to enhance the flavor profile and add complexity to the cheddar.

Brie Cheese and Most Suitable Milk

Brie cheese is best made with whole milk, specifically from cows. The high fat content in the milk is crucial for achieving the creamy, decadent texture that defines brie.

Milk Recommendations for Various Cheese Types

Selecting the appropriate milk is fundamental to successful cheesemaking. The table below provides a concise overview of recommended milk types for various cheese styles, along with their expected flavor profiles.

| Cheese Type | Ideal Milk | Flavor Profile | Notes |

|---|---|---|---|

| Mozzarella | Whole Cow’s Milk | Mild, milky, slightly tangy | High protein content is essential for stretch. |

| Cheddar | Whole Cow’s Milk, Raw Cow’s Milk, Blends | Varies depending on aging and milk source; ranges from mild and creamy to sharp and complex. | Raw milk often yields more complex flavors; aging is crucial. |

| Brie | Whole Cow’s Milk | Creamy, buttery, mushroomy | High fat content contributes to the characteristic texture. |

| Feta | Sheep’s Milk, Goat’s Milk, Cow’s Milk (or blends) | Salty, tangy, sometimes slightly grassy (goat) | Sheep’s milk provides the most traditional flavor; blends are common. |

| Parmesan | Part-skim Cow’s Milk | Nutty, savory, complex | Aging is a long process, with specific regulations for true Parmigiano-Reggiano. |

Outcome Summary

In conclusion, selecting the right milk is the cornerstone of exceptional cheesemaking. By understanding milk types, compositions, quality assessment, and processing techniques, you’re empowered to create cheeses that are not only delicious but also a testament to your skill and knowledge. Armed with this guide, you’re now equipped to navigate the world of milk with confidence, transforming every cheesemaking attempt into a rewarding culinary adventure.

Happy cheesemaking!