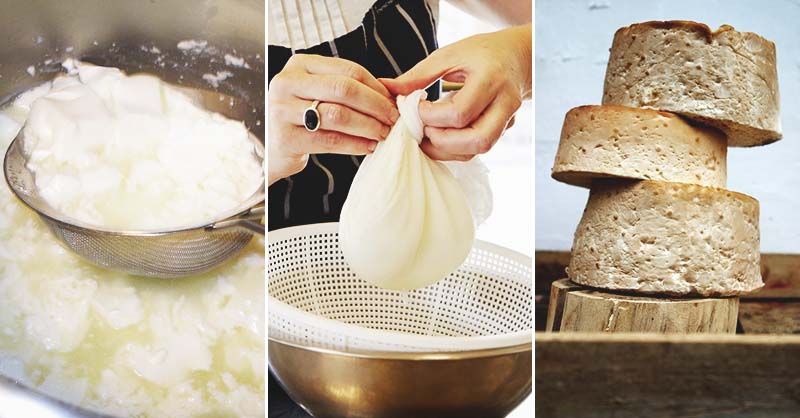

Embark on a flavorful journey with How to Tell When Your Homemade Cheese is Ready to Eat! Crafting cheese at home is a rewarding experience, but knowing when your creation has reached its peak is key. This guide unravels the secrets behind recognizing the perfect moment to savor your homemade cheese, ensuring every bite is a delight.

From visual cues like color and texture to the subtle nuances of aroma and taste, we’ll explore the sensory signals that indicate cheese readiness. We’ll delve into the science of ripening, providing practical tips and techniques to help you master the art of cheesemaking and enjoy the fruits (or cheeses!) of your labor.

Visual Cues of Cheese Readiness

Knowing when your homemade cheese is ready to eat is a crucial part of the cheesemaking process. While factors like time and temperature play a role, visual cues offer a more immediate and reliable way to assess ripeness. Observing the cheese’s appearance throughout the aging process provides valuable insights into its development and readiness.

Appearance During Ripening

The appearance of cheese changes dramatically as it ripens. These visual transformations are a direct result of the complex biochemical processes happening within the cheese, driven by enzymes and microorganisms. Observing these changes is key to determining the optimal eating window.

Color Changes During Maturation

Color is a significant indicator of cheese maturity. The color shifts reflect the breakdown of proteins, fats, and lactose, along with the growth of surface molds and bacteria.

- Fresh Cheeses: Fresh cheeses, like mozzarella or ricotta, generally have a bright white color. As they age (though they are typically eaten fresh), they might develop a slightly yellowish tinge due to the oxidation of fats, particularly if exposed to air.

- Bloomy Rind Cheeses (e.g., Brie, Camembert): These cheeses start with a white, sometimes slightly blue-tinged, rind. As they ripen, the rind becomes denser and may develop reddish-brown spots or streaks. The paste (the inside of the cheese) transitions from a firm, chalky texture to a creamy, almost melting consistency. The color of the paste itself changes from bright white to pale yellow or ivory.

- Washed-Rind Cheeses (e.g., Limburger, Taleggio): Washed-rind cheeses develop a characteristic orange or reddish-brown rind due to the Brevibacterium linens bacteria. The intensity of the color deepens as the cheese ripens. The paste usually transitions from a pale color to a more golden or yellowish hue.

- Blue Cheeses (e.g., Roquefort, Gorgonzola): Blue cheeses are characterized by blue or green veins of mold (Penicillium roqueforti). As the cheese matures, these veins grow and spread throughout the paste. The paste color can vary from white to ivory or pale yellow. The color of the mold intensifies, and the cheese develops a more complex flavor profile.

- Hard Cheeses (e.g., Cheddar, Parmesan): Hard cheeses often start with a pale yellow color. As they age, the color can deepen to a more golden or amber hue, especially in the center of the cheese. The development of tyrosine crystals (small, crunchy protein crystals) on the surface is another visual cue of aging.

Characteristics of a Finished Cheese

A finished cheese will exhibit specific visual characteristics that indicate it has reached its peak flavor and texture. These characteristics vary depending on the cheese type.

- Texture:

- Soft Cheeses: Soft cheeses should be yielding to the touch. The paste should be creamy and smooth, often with a slight give when pressed.

- Semi-Hard Cheeses: Semi-hard cheeses should be firm but still have some flexibility. The texture should be smooth and not crumbly.

- Hard Cheeses: Hard cheeses should be firm and dense. They may have a slightly granular texture or contain tyrosine crystals.

- Surface Characteristics:

- Bloomy Rind Cheeses: The rind should be intact and evenly covered with a white, slightly fluffy mold.

- Washed-Rind Cheeses: The rind should be sticky and slightly tacky to the touch, with a vibrant orange or reddish-brown color.

- Blue Cheeses: The blue veins should be evenly distributed throughout the paste. The surface may have a slightly moist appearance.

- Hard Cheeses: The surface may be dry and firm, sometimes with a natural rind or a wax coating. Tyrosine crystals may be visible.

- Internal Appearance: The internal structure is an important visual cue. For example, in cheddar, the absence of large air holes indicates proper aging. In blue cheese, the distribution and intensity of the blue veins are crucial.

Texture Indicators for Cheese Ripeness

Assessing the texture of your homemade cheese is a crucial step in determining its readiness to eat. This involves using your senses, particularly touch, to gauge the cheese’s firmness, pliability, and creaminess. The texture changes significantly as cheese ripens, transforming from a young, sometimes rubbery state to a more complex and nuanced profile.

Assessing Texture Through Touch

The sense of touch provides valuable insights into the internal structure and moisture content of cheese. By gently handling the cheese, you can discern subtle changes that indicate its progression towards optimal ripeness. This tactile examination, combined with visual and olfactory cues, offers a comprehensive understanding of the cheese’s readiness.To assess the texture effectively:

- Firmness: Gently press on the surface of the cheese. A young cheese will often feel firm and may spring back quickly. As it ripens, it will become softer and more yielding.

- Pliability: Consider how the cheese bends or gives way. Some cheeses, like soft-ripened varieties, will become increasingly pliable as they mature.

- Creaminess: Observe the texture near the surface and in any cut sections. Creaminess increases with age in many cheeses, indicating the breakdown of proteins and fats.

Texture Comparison: Young vs. Ripe Cheese

The texture of cheese evolves dramatically as it ripens. The following table highlights key differences between a young and a fully ripened cheese, using examples to illustrate the changes.

| Cheese Type | Young Cheese Texture | Ripe Cheese Texture | Example |

|---|---|---|---|

| Cheddar | Firm, slightly rubbery, smooth | Firm, but with a slightly crumbly texture, crystals may be present | A young cheddar might be used for melting in a grilled cheese, while a fully ripened cheddar is ideal for snacking. |

| Brie | Firm, chalky interior, possibly with a slight “bounce” | Soft, creamy, with a runny edge near the rind | A young brie might have a firm, almost chalky texture. A ripe brie will be very soft and spreadable. |

| Goat Cheese (Fresh) | Crumbly, firm | Soft, spreadable, slightly runny | Fresh goat cheese is typically crumbly. As it ages, it becomes smoother and easier to spread. |

| Parmesan | Very hard, dense, and smooth | Hard, granular, with visible protein crystals | Young Parmesan is very hard. A ripe Parmesan will be hard but also have a granular texture due to protein crystal formation. |

Aroma Evaluation for Cheese Ripeness

The aroma of your homemade cheese is a crucial indicator of its readiness to eat. It’s a complex interplay of volatile compounds that develop during the aging process, and these aromas can tell you a great deal about the cheese’s flavor profile and whether it’s reached its peak. Recognizing the difference between pleasant and undesirable smells is key to enjoying your cheese at its best and avoiding potential spoilage.

Pleasant Aromas Associated with Cheese Varieties at Peak Flavor

The specific aromas that develop in cheese depend on the type of cheese, the cultures used, and the aging conditions. When a cheese is at its peak, the aroma is often complex and inviting.

- Cheddar: A sharp, nutty, and sometimes slightly lactic aroma. Older cheddars may develop more complex aromas with hints of earthiness or caramel.

- Brie: A mushroomy, earthy, and sometimes slightly ammoniacal aroma, especially near the rind. The intensity of the aroma increases as the cheese ripens.

- Camembert: Similar to Brie, but often with a stronger, more pungent aroma. The aroma should be balanced and not overwhelmingly ammonia-like.

- Blue Cheese (e.g., Roquefort, Stilton): A distinctively pungent aroma, often described as a combination of barnyard, peppery, and sometimes sweet notes. The aroma is a result of the blue mold (Penicillium) growth.

- Goat Cheese (e.g., Chevre): A fresh, tangy, and sometimes slightly goaty aroma. As the cheese ages, the aroma can become more intense and earthy.

- Parmesan: A complex, nutty, and savory aroma. Aged Parmesan develops deeper aromas with hints of fruit or caramel.

- Swiss Cheese: A sweet, nutty aroma with hints of caramel. The aroma becomes more pronounced as the cheese ages.

Aromas Indicating Spoilage or Under-Ripening

Certain aromas can signal that your cheese is not ready to eat or, worse, is spoiled. Being able to distinguish these aromas is crucial for food safety and enjoyment.

- Ammonia: A strong, sharp ammonia smell, especially in Brie or Camembert, can indicate that the cheese has been aged too long or that the rind is breaking down excessively. Small amounts of ammonia near the rind are normal, but a pervasive ammonia smell throughout the cheese is a sign of spoilage.

- Rancid or Sour: A rancid or sour smell often indicates that the cheese has gone bad. This can be caused by the breakdown of fats or the growth of undesirable bacteria.

- Musty or Moldy: While some molds are desirable in cheese, a musty or moldy smell that isn’t characteristic of the cheese type can indicate spoilage. This can be caused by the growth of undesirable molds.

- Off-Flavors: Any other unusual or unpleasant smells, such as a chemical or metallic odor, should be viewed with suspicion. These aromas could indicate contamination or an issue with the aging process.

- Lack of Aroma (Under-Ripening): If the cheese lacks any significant aroma, it might be under-ripe. The flavor may be bland, and the texture might be too firm.

Taste Testing for Cheese Readiness

Taste is the ultimate test of cheese readiness. While visual, textural, and aromatic cues provide valuable insights, the final verdict rests on the flavor profile. This section details how to properly taste cheese to assess its readiness, evaluate its flavor components, and understand the nuances that signal peak ripeness.

Proper Tasting Method

To accurately evaluate cheese readiness, a methodical approach to tasting is essential. This ensures that the palate is cleansed and the cheese’s true flavors can be appreciated.To prepare for tasting, it’s helpful to cleanse the palate.

- Start with a neutral palate cleanser, such as plain crackers or a slice of unflavored bread.

- Take a small bite of the cracker or bread and chew it thoroughly. This helps to remove any lingering flavors from previous foods or drinks.

- Follow with a sip of water, allowing it to coat the mouth and neutralize any remaining tastes.

- Take a small piece of the cheese, about the size of a dime, and place it on your tongue.

- Allow the cheese to melt and spread across your palate.

- Concentrate on the initial flavors, the evolution of flavors as the cheese melts, and the lingering aftertaste.

- Note the texture, the acidity, the saltiness, and the overall complexity.

Flavor Profiles at Peak Ripeness

Different cheese types develop distinct flavor profiles as they ripen. Understanding these profiles allows cheesemakers and enthusiasts to identify when a cheese has reached its peak. The following are examples of flavor characteristics for different cheese types:

| Cheese Type | Expected Flavor Profile at Peak Ripeness |

|---|---|

| Cheddar | A well-aged cheddar exhibits a complex flavor profile. |

| Brie | A ripe Brie should have a rich, buttery flavor with hints of mushroom and a slightly earthy aroma. |

| Gouda | Mature Gouda develops a caramel-like sweetness with notes of butterscotch and a slight nuttiness. |

Evaluating Acidity, Saltiness, and Complexity

The balance of acidity, saltiness, and complexity defines the quality of a cheese. Each of these components contributes to the overall flavor experience and provides clues about the cheese’s ripeness.

-

Acidity: Acidity in cheese contributes to its tanginess and can be an indicator of its age and ripening process.

A young cheese might have a bright, lactic acidity, while a well-aged cheese could exhibit a more complex, mellow acidity.

-

Saltiness: Salt plays a crucial role in cheese flavor, texture, and preservation.

The salt level should be balanced, enhancing the other flavors without being overpowering.

The saltiness will vary depending on the cheese type and production method.

-

Complexity: Complexity refers to the range and depth of flavors present in the cheese.

A complex cheese will have multiple layers of flavor, with different notes appearing at different stages of tasting.

This could include flavors like fruity, nutty, earthy, or spicy notes.

Methods for Cheese Ripening and Aging

Cheese ripening and aging is a fascinating process that transforms fresh curds into a diverse array of flavors, textures, and aromas. Understanding how to control this process is crucial for achieving the desired characteristics in your homemade cheese. This section explores the environmental factors that influence ripening, provides practical tips for home cheese aging, and Artikels the typical aging process for a specific cheese type.

Environmental Factors Influencing Cheese Ripening

The environment in which cheese ages plays a pivotal role in its development. Temperature and humidity are the two primary factors that cheese makers carefully control to manipulate the ripening process. Variations in these parameters directly impact the activity of enzymes, bacteria, and molds, which are responsible for breaking down proteins, fats, and lactose, leading to the development of characteristic flavors and textures.

- Temperature: Temperature affects the rate of enzymatic and microbial activity. Higher temperatures generally accelerate ripening, while lower temperatures slow it down.

- Example: A soft-ripened cheese like Brie, aged at a warmer temperature (around 60-65°F or 15-18°C), will ripen more quickly than a hard cheese like Cheddar, which is typically aged at a cooler temperature (around 50-55°F or 10-13°C).

The warmer environment encourages the growth of the surface mold (like

-Penicillium candidum* in Brie), resulting in a soft, creamy texture and a pungent aroma.

- Example: A soft-ripened cheese like Brie, aged at a warmer temperature (around 60-65°F or 15-18°C), will ripen more quickly than a hard cheese like Cheddar, which is typically aged at a cooler temperature (around 50-55°F or 10-13°C).

- Humidity: Humidity influences the moisture content of the cheese, which affects the growth of surface molds and bacteria, and also the overall texture.

- Example: High humidity, often around 80-95%, is crucial for the development of a bloomy rind on cheeses like Camembert. This humid environment provides the ideal conditions for the

-Penicillium candidum* mold to thrive, creating the characteristic white rind.Conversely, too low humidity can lead to the cheese drying out, cracking, and inhibiting the growth of beneficial molds.

- Example: High humidity, often around 80-95%, is crucial for the development of a bloomy rind on cheeses like Camembert. This humid environment provides the ideal conditions for the

- Air Circulation: Air circulation also plays a role, especially in preventing the build-up of undesirable molds and allowing for even ripening.

- Example: Cheeses aged in caves or controlled environments often have a gentle air flow to help control humidity and encourage the growth of desired molds and bacteria.

Procedures for Controlling the Ripening Process in a Home Environment

Controlling the ripening process at home requires careful attention to detail and a few essential tools. By understanding the interplay of temperature, humidity, and air circulation, you can create an environment conducive to successful cheese aging.

- Temperature Control:

- A dedicated refrigerator with adjustable temperature settings is ideal.

- Alternatively, use a wine cooler or a spare refrigerator.

- Monitor the temperature regularly with a thermometer, ensuring the environment remains within the optimal range for the cheese type.

- Humidity Control:

- A hygrometer is essential for measuring humidity levels.

- A cheese cave or a dedicated cheese aging refrigerator often includes humidity control.

- If using a regular refrigerator, place a container of water inside to increase humidity.

- Adjust the water container’s surface area to modulate humidity. A larger surface will increase humidity, and a smaller one will decrease it.

- Air Circulation:

- Ensure adequate air circulation within the aging environment.

- Avoid overcrowding the cheese.

- Use a small fan on a low setting (if necessary) to promote air movement.

- Storage Recommendations:

- Cheese Cloth: Wrap the cheese in cheesecloth, which allows for air circulation while protecting the cheese from drying out.

- Waxing: Waxing cheese provides a barrier against moisture loss and contamination, especially for hard cheeses.

- Vacuum Sealing: Vacuum sealing can be used for specific cheeses, but it can also lead to anaerobic conditions that might promote undesirable bacteria growth, so it’s generally not recommended for all types.

- Turning: Regularly turning the cheese ensures even ripening and prevents the cheese from sticking to the surface.

- Monitoring: Regularly inspect the cheese for any signs of mold growth, unwanted odors, or texture changes.

Flow Chart: Typical Aging Process for Cheddar Cheese

The following flow chart Artikels the typical aging process for Cheddar cheese, a hard cheese that undergoes significant changes during its maturation.

| Step | Description | Environmental Conditions | Duration | Expected Changes |

|---|---|---|---|---|

| 1. Pressing and Salting | The curds are pressed to remove whey, forming a firm block. Salt is added, either by rubbing or brining. | N/A | 1-3 days | Firm texture, salt penetration, initial flavor development. |

| 2. Initial Drying | The cheese is allowed to dry slightly to form a rind. | Temperature: 50-55°F (10-13°C); Humidity: 75-85% | 1-2 weeks | Rind formation, moisture loss, surface drying. |

| 3. Aging (Primary Phase) | The cheese is aged under controlled conditions, allowing for enzymatic and microbial activity. | Temperature: 50-55°F (10-13°C); Humidity: 75-85%; Moderate air circulation. | 2 months – 2 years (or longer) | Breakdown of proteins and fats, development of complex flavors, texture changes from firm to crumbly. |

| 4. Turning | The cheese is turned periodically to ensure even aging and prevent sticking. | N/A | Every 1-2 weeks | Even moisture distribution, uniform rind development. |

| 5. Monitoring | The cheese is regularly inspected for signs of unwanted mold growth, texture changes, or off-flavors. | N/A | Throughout the aging process | Early detection of potential problems, assessment of ripening progress. |

| 6. Tasting and Evaluation | The cheese is tasted at regular intervals to assess flavor development and determine when it has reached the desired maturity. | N/A | Variable, based on the desired age and flavor profile | Determination of readiness for consumption. |

Troubleshooting Cheese Ripening Issues

Ripening cheese can be a rewarding experience, but it’s not without its challenges. Understanding common problems and how to address them is crucial for achieving successful results. This section will explore typical issues encountered during cheese ripening and offer practical solutions to help you produce delicious, safe, and aesthetically pleasing cheeses.

Undesirable Mold Growth

Mold is a natural part of cheese ripening, but not all molds are welcome. Identifying and managing unwanted mold growth is essential for maintaining cheese quality and safety.

- Black Mold: This type of mold is generally undesirable. It can produce mycotoxins and is often associated with poor sanitation. If black mold appears, discard the affected cheese immediately.

- Blue/Green Mold (Undesirable Varieties): While some blue molds are used intentionally in blue cheese, the presence of other blue or green molds, especially if they are fuzzy or spreading aggressively, can indicate spoilage. These molds may produce off-flavors and should be addressed promptly.

- Pink or Red Mold: Pink or red molds are often an indication of spoilage and can produce undesirable flavors. These molds can also indicate the presence of bacteria. Discard any cheese with pink or red mold growth.

- Solutions for Undesirable Mold:

- Improve Sanitation: Thoroughly clean and sanitize all equipment and the ripening environment to prevent mold contamination.

- Control Humidity: Adjust humidity levels to discourage unwanted mold growth. Higher humidity favors mold growth.

- Increase Air Circulation: Adequate air circulation helps to prevent mold growth. Use a fan to circulate air in the ripening environment.

- Surface Treatment: Regularly wash the cheese rind with a brine solution or other appropriate wash to control mold growth.

- Isolate Affected Cheeses: If you notice mold on a cheese, isolate it from other cheeses to prevent cross-contamination.

Unwanted Texture Issues

Texture is a key characteristic of cheese, and unexpected changes can ruin the final product. Several factors can lead to undesirable textures.

- Dry, Crumbly Texture: This can result from excessive moisture loss during ripening.

- Solutions for Dry, Crumbly Texture:

- Increase Humidity: Raise the humidity in the ripening environment to slow moisture loss.

- Reduce Air Circulation: Decrease air circulation to retain moisture.

- Proper Coating: Consider using a wax coating or cheese cloth to prevent moisture loss.

- Slimy or Sticky Rind: This often indicates excessive moisture and the growth of unwanted bacteria or molds.

- Solutions for Slimy or Sticky Rind:

- Reduce Humidity: Lower the humidity in the ripening environment.

- Increase Air Circulation: Improve air circulation to dry the rind.

- Rind Washing: Regularly wash the rind with a brine solution.

- Overly Soft or Runny Cheese: This can occur if the cheese ripens too quickly or at too high a temperature.

- Solutions for Overly Soft or Runny Cheese:

- Lower Temperature: Reduce the ripening temperature to slow down the ripening process.

- Adjust Humidity: Maintain appropriate humidity levels.

- Reduce Ripening Time: If the cheese is ripening too quickly, reduce the overall ripening time.

Off-Flavors and Odors

Unpleasant flavors and odors can be a sign of problems during cheese ripening. Identifying the cause is crucial for preventing these issues in future batches.

- Ammonia Odor: This can indicate excessive protein breakdown, often caused by high humidity and/or high temperatures.

- Solutions for Ammonia Odor:

- Reduce Humidity: Lower the humidity in the ripening environment.

- Lower Temperature: Reduce the ripening temperature.

- Increase Air Circulation: Improve air circulation.

- Adjust Washing: Regularly wash the cheese rind with a brine solution to control surface bacteria.

- Bitter Taste: This can be caused by excessive protein breakdown or the presence of certain molds.

- Solutions for Bitter Taste:

- Control Humidity and Temperature: Maintain appropriate humidity and temperature levels.

- Adjust Ripening Time: Shorten the ripening time.

- Use Proper Starter Cultures: Ensure the use of appropriate starter cultures to control the ripening process.

- Soapy Taste: This can be due to the presence of certain bacteria or the use of certain types of milk.

- Solutions for Soapy Taste:

- Use High-Quality Milk: Start with high-quality milk.

- Control Temperature: Maintain appropriate ripening temperatures.

- Adjust Starter Cultures: Use a different starter culture.

Ripening Environment Adjustments

The ripening environment plays a crucial role in cheese development. Correcting issues often involves making adjustments to temperature, humidity, and air circulation.

- Temperature:

- Too High: Accelerates ripening, potentially leading to off-flavors and texture problems.

- Too Low: Slows ripening, which may result in a cheese that never fully develops its flavor or texture.

- Solutions: Monitor and adjust the temperature using a refrigerator or cheese cave with temperature control.

- Humidity:

- Too High: Promotes mold growth and can lead to a slimy rind and ammonia production.

- Too Low: Causes excessive moisture loss, resulting in a dry, crumbly cheese.

- Solutions: Use a hygrometer to monitor humidity and adjust with a humidifier or dehumidifier.

- Air Circulation:

- Insufficient: Can lead to uneven ripening and mold growth.

- Excessive: Can cause the cheese to dry out too quickly.

- Solutions: Use a fan to circulate air. Adjust the fan speed or position to achieve the desired air circulation.

Desirable vs. Undesirable Mold Examples

Understanding the difference between beneficial and harmful molds is crucial for cheese ripening.

- Desirable Molds:

- Penicillium candidum: This white mold is commonly used in bloomy rind cheeses like Brie and Camembert. It creates a soft, edible rind and contributes to the cheese’s creamy texture and delicate flavor.

- Penicillium roqueforti: This blue-green mold is used in blue cheeses. It creates the characteristic blue veins and contributes to the cheese’s pungent flavor.

Image Description: A close-up of a Brie cheese, showing a uniform, white, velvety rind. The rind is unbroken and appears to be well-developed, with no signs of discoloration or undesirable mold growth. The cheese itself appears soft and creamy.

Image Description: A close-up of a Roquefort cheese, displaying the characteristic blue-green veins running through the cheese paste. The paste itself is off-white or ivory-colored, and the veins are evenly distributed, indicating proper mold development.

- Undesirable Molds:

- Black Mold (various species): Can produce mycotoxins and is generally associated with poor sanitation. It appears as black, fuzzy patches.

- Fuzzy Green/Blue Mold (various species): Can lead to off-flavors and textures. It appears as a fuzzy or spreading growth.

- Pink or Red Mold (various species): Can indicate spoilage and can produce off-flavors.

Image Description: A cheese with a patch of black, fuzzy mold. The mold is dark in color and appears to be growing aggressively on the surface of the cheese. This is an example of an undesirable mold.

Image Description: A cheese with patches of pink mold. The mold is a bright pink color and is growing on the surface of the cheese. This is an example of an undesirable mold.

Cheese-Specific Indicators of Readiness

Understanding the specific indicators of readiness is crucial for determining when your homemade cheese has reached its peak flavor and texture. Different cheese types mature in unique ways, exhibiting distinct visual, textural, and aromatic cues. Recognizing these specific signals allows you to enjoy your cheese at its best.

Cheddar Cheese Readiness Indicators

Cheddar cheese, a hard cheese, requires careful monitoring during the aging process. Its readiness is signaled by a combination of visual, textural, and aromatic changes.

- Visual Cues: The color of cheddar cheese deepens as it ages, progressing from a pale yellow to a deeper, more golden hue. Small, crystalline structures, often referred to as “calcium lactate crystals,” may appear on the surface, indicating the breakdown of proteins and the development of flavor.

- Textural Cues: The texture of cheddar evolves from a relatively firm and slightly elastic consistency to a more firm, yet crumbly texture as it ages. Younger cheddar is smoother, while older cheddar becomes more granular.

- Aromatic Cues: A well-aged cheddar will develop a complex aroma. The scent will evolve from a mild, lactic aroma to a more pronounced, savory, and sometimes nutty fragrance. The intensity of the aroma often correlates with the age and flavor complexity.

Brie Cheese Readiness Indicators

Brie, a soft, bloomy-rind cheese, is known for its delicate flavors and textures. Its readiness is characterized by the appearance of a specific rind and changes in its interior.

- Visual Cues: The rind of Brie should be a consistent, white or slightly off-white color with a uniform, velvety texture. The cheese should be relatively uniform, and any areas with blue or green mold (other than intentional additions) are typically signs of spoilage.

- Textural Cues: The interior of Brie should be soft and creamy, with a slightly runny consistency at the edges when ripe. The center might be firmer, but it should soften as the cheese ripens. The texture should be spreadable without being excessively liquid.

- Aromatic Cues: A ripe Brie will have a characteristic aroma of mushrooms, earth, and a hint of ammonia. The ammonia smell can be more pronounced as the cheese ages, but it should not be overpowering. An overly strong ammonia smell indicates the cheese may be overripe.

Mozzarella Cheese Readiness Indicators

Mozzarella, a fresh, stretched-curd cheese, is best enjoyed soon after it is made. Its readiness is primarily determined by its texture and appearance.

- Visual Cues: Fresh mozzarella should be a bright white color, with a smooth, slightly shiny surface. It may have a slight translucence.

- Textural Cues: The texture of mozzarella should be soft and pliable, yet firm enough to hold its shape. When cut, it should have a slight springiness. It should be easy to tear.

- Aromatic Cues: Mozzarella has a mild, milky aroma. It should smell fresh and clean, without any strong or off-putting odors.

Parmesan Cheese Readiness Indicators

Parmesan, a hard, granular cheese, requires extended aging to develop its characteristic flavor and texture. Its readiness is judged by its firm texture and robust aroma.

- Visual Cues: Parmesan cheese typically has a light yellow color, with a slightly granular appearance. As it ages, small tyrosine crystals, similar to those in cheddar, may become more visible on the surface.

- Textural Cues: The texture of Parmesan should be very hard and granular. It should be easy to grate or break into pieces. It should be dry, not moist.

- Aromatic Cues: Parmesan has a complex aroma, characterized by a nutty, savory, and slightly fruity fragrance. The aroma should be strong and well-defined.

Gouda Cheese Readiness Indicators

Gouda, a semi-hard cheese, showcases distinct signs of maturity through its rind, texture, and fragrance.

- Visual Cues: The rind of Gouda can vary from a natural, waxed coating to a cloth-bound appearance. The color can range from pale yellow to a darker, reddish-brown depending on the aging process and the rind treatment. Look for a consistent appearance without excessive mold growth (unless intentionally part of the aging process).

- Textural Cues: Young Gouda is relatively smooth and flexible, while aged Gouda becomes firmer, more crystalline, and slightly crumbly. The texture should be smooth, without being overly soft or rubbery.

- Aromatic Cues: The aroma of Gouda becomes more complex with age, developing notes of caramel, butterscotch, and toasted nuts. Younger Gouda will have a milder, milky aroma. A slight sweetness is often present in the scent.

Equipment and Tools for Cheese Evaluation

Assessing the readiness of your homemade cheese requires a few essential tools. These tools help you evaluate the cheese’s visual appearance, texture, aroma, and taste, providing a comprehensive understanding of its development. Proper use and maintenance of these tools are crucial for accurate assessments and maintaining food safety.

Essential Tools for Cheese Evaluation

Here’s a breakdown of the essential tools needed for cheese evaluation:

- Cheese Knives: Cheese knives are designed to cut through cheese cleanly and efficiently, allowing you to observe the internal structure and texture. Different types of knives serve different purposes.

- Soft Cheese Knife: This knife typically has a thin, flexible blade and often holes to prevent the cheese from sticking. It’s ideal for soft cheeses like Brie or Camembert.

- Hard Cheese Knife: These knives have a sturdy, often serrated blade, designed to cut through the harder rinds of cheeses like Cheddar or Parmesan.

- Cheese Plane: Used for slicing thin, even slices of semi-hard and hard cheeses.

- Cheese Probe: A cheese probe is a thin, stainless steel tool used to assess the internal texture of the cheese without cutting into it excessively. It’s especially useful for monitoring the aging of larger cheeses.

- Tasting Spoons: Tasting spoons are essential for sampling the cheese. Use clean spoons for each tasting to avoid cross-contamination and ensure accurate flavor evaluation.

- Notebook and Pen: Keeping detailed records of your cheese-making process and observations is critical. Note the date, cheese type, and your observations about its appearance, texture, aroma, and taste.

- Clean Cutting Board: Use a dedicated, clean cutting board for cheese evaluation to prevent contamination.

- Scale: Weigh the cheese regularly to track moisture loss during the aging process.

Using Cheese Evaluation Tools Effectively

Proper technique is key to getting accurate results when using these tools.

- Cheese Knives:

- When using a cheese knife, make clean, decisive cuts. Avoid sawing, which can damage the cheese and alter its texture.

- For soft cheeses, use a gentle sawing motion with the soft cheese knife.

- For hard cheeses, apply firm, even pressure.

- Cheese Probe:

- Insert the probe gently into the cheese, aiming for the center.

- Withdraw the probe slowly, observing the texture on the probe’s tip. This gives you an indication of the cheese’s consistency throughout.

- Tasting Spoons:

- Take small, focused bites to fully appreciate the cheese’s flavors.

- Taste the cheese in a quiet, neutral environment to avoid distractions.

- Clean your palate between tastings, perhaps with water or plain crackers.

- Notebook and Pen:

- Be detailed in your descriptions. Note the color, the feel, the smell, and, of course, the taste.

- Record the date and any relevant information, such as the cheese-making process and aging conditions.

Cleaning and Maintaining Cheese Evaluation Tools

Maintaining the cleanliness of your tools is crucial for food safety and accurate assessments.

- Cleaning Cheese Knives:

- Wash cheese knives with warm, soapy water after each use.

- Rinse thoroughly and dry immediately to prevent rust.

- Store knives in a safe place, such as a knife block or drawer, to protect the blades.

- Cleaning Cheese Probes:

- Clean the cheese probe immediately after use.

- Wash it with warm, soapy water.

- Rinse thoroughly and dry it.

- Consider sterilizing the probe with boiling water periodically, especially when evaluating cheeses that have been aging for a long time.

- Cleaning Tasting Spoons:

- Wash tasting spoons thoroughly with warm, soapy water.

- Rinse them well and dry them completely.

- Use a separate, clean spoon for each sample to prevent cross-contamination.

- Cleaning Cutting Boards:

- Wash the cutting board with warm, soapy water after each use.

- Rinse thoroughly and sanitize it with a solution of diluted bleach or a commercial food-safe sanitizer.

- Dry completely before storing.

- General Maintenance:

- Inspect your tools regularly for any signs of damage or wear.

- Sharpen knives as needed to ensure clean cuts.

- Replace any tools that are damaged or worn out.

Conclusive Thoughts

In conclusion, mastering How to Tell When Your Homemade Cheese is Ready to Eat involves understanding the interplay of sight, touch, smell, and taste. By honing your sensory skills and applying the knowledge gained in this guide, you’ll transform your cheesemaking from a hobby into a true culinary art. So, embrace the process, trust your instincts, and prepare to enjoy the delicious rewards of perfectly ripened, homemade cheese!