Ever wondered what “whey” actually is, or why some cheeses have a “bloomy rind”? Welcome to the fascinating world of cheesemaking, where understanding the language is the first step to crafting your own delicious creations. This guide, focusing on How to Understand Basic Cheesemaking Terminology, is your key to unlocking the secrets behind your favorite cheeses and empowering you to embark on your own cheesemaking journey.

From ancient techniques to modern methods, we’ll explore the essential terms that will transform you from a cheese novice into a confident cheesemaker.

Cheesemaking is a culinary art steeped in history, evolving over millennia from simple preservation methods to a diverse range of flavors and textures. This journey through cheesemaking terminology will cover the basics, from the fundamental components of milk to the intricate processes of coagulation, aging, and flavor development. We’ll demystify the jargon and equip you with the knowledge to navigate the world of cheese with confidence, whether you’re reading a recipe, visiting a cheese shop, or dreaming of creating your own artisanal masterpieces.

The World of Cheesemaking Terminology

Understanding cheesemaking terminology is crucial for anyone venturing into the world of cheese, from the home enthusiast to the aspiring artisan. Learning the specific vocabulary unlocks a deeper appreciation for the craft, allowing for more effective communication, recipe comprehension, and ultimately, superior cheesemaking results. It’s like learning the language of a new culture; you gain a richer understanding and can fully immerse yourself in the experience.The benefits extend beyond simply understanding recipes.

Knowing the terms allows you to: troubleshoot problems effectively, replicate successful results, experiment with confidence, and participate in cheesemaking discussions with authority. It elevates your experience from a casual hobby to a skilled practice.

A Brief History of Cheesemaking

Cheesemaking boasts a history stretching back millennia, originating in the Neolithic period. The exact origins are debated, but it’s likely that cheese was discovered accidentally. Milk, stored in animal stomachs (used as early containers), would have curdled due to the presence of rennet, an enzyme found in the stomach lining. The resulting solid mass was likely the first cheese.Over time, cheesemaking techniques evolved across different cultures, adapting to local environments and resources.

The Romans, for example, were prolific cheesemakers, developing various cheeses and spreading their knowledge throughout their empire. Monasteries played a crucial role in preserving and refining cheesemaking techniques during the Middle Ages, contributing to the development of many classic European cheeses.The Industrial Revolution brought about significant changes, including mass production and pasteurization. Pasteurization, the process of heating milk to kill harmful bacteria, extended the shelf life of cheese and made it safer for consumption.

Today, cheesemaking encompasses a spectrum of practices, from traditional artisanal methods to large-scale commercial operations, each with its own specific terminology. The evolution of cheesemaking is a testament to human ingenuity and the enduring appeal of this versatile food.

Essential Dairy Terms

Understanding the language of cheesemaking is crucial for success. This section dives into essential dairy terms, focusing on the foundational ingredient: milk. We’ll explore the processes it undergoes and the components that make it so versatile for cheesemaking.

Pasteurization, Homogenization, and Raw Milk

The treatment of milk before cheesemaking significantly impacts the final product. Let’s clarify these key terms:* Pasteurization: This process involves heating milk to a specific temperature for a set time to kill harmful bacteria. It’s a heat treatment that enhances safety by eliminating pathogens like

- E. coli* and

- Salmonella*. Pasteurization also extends the shelf life of milk.

Example

* The most common method, High-Temperature Short-Time (HTST) pasteurization, heats milk to 72°C (161°F) for 15 seconds.

Homogenization

This process breaks down the fat globules in milk into smaller particles and disperses them evenly throughout the milk. This prevents the cream from separating and rising to the top. Homogenization affects the texture and appearance of cheese.

Effect

* Homogenized milk results in a smoother, more consistent texture in cheeses.

Raw Milk

Raw milk is milk that has not been pasteurized. It contains all its natural bacteria, both beneficial and potentially harmful. Cheesemakers who use raw milk must adhere to strict hygiene practices and often age their cheeses for a minimum period to allow for the growth of beneficial bacteria and reduce the risk of pathogens.

Consideration

* Raw milk cheesemaking offers unique flavor profiles due to the diverse microbial communities present, but it also carries a higher risk.

The Role of Milk Fat and Protein in Cheesemaking

Milk fat and protein are the primary building blocks of cheese, determining its texture, flavor, and overall characteristics. Their proportions and qualities greatly influence the cheesemaking process and the final product.* Milk Fat: Milk fat contributes to the richness, flavor, and texture of cheese. Higher fat content generally results in a creamier, more flavorful cheese. Fat also traps flavor compounds, enhancing the taste experience.

Example

* Cheeses like Brie and Camembert, with higher fat content, have a softer, richer texture.

Milk Protein

Primarily casein, milk protein coagulates during cheesemaking, forming the cheese curd. The amount and type of protein affect the cheese’s structure, firmness, and ability to hold its shape.

Formula

* Casein coagulation is often initiated by the addition of rennet or acids, which cause the proteins to bind together.

Example

* The protein structure in cheddar cheese contributes to its firm, easily sliced texture.

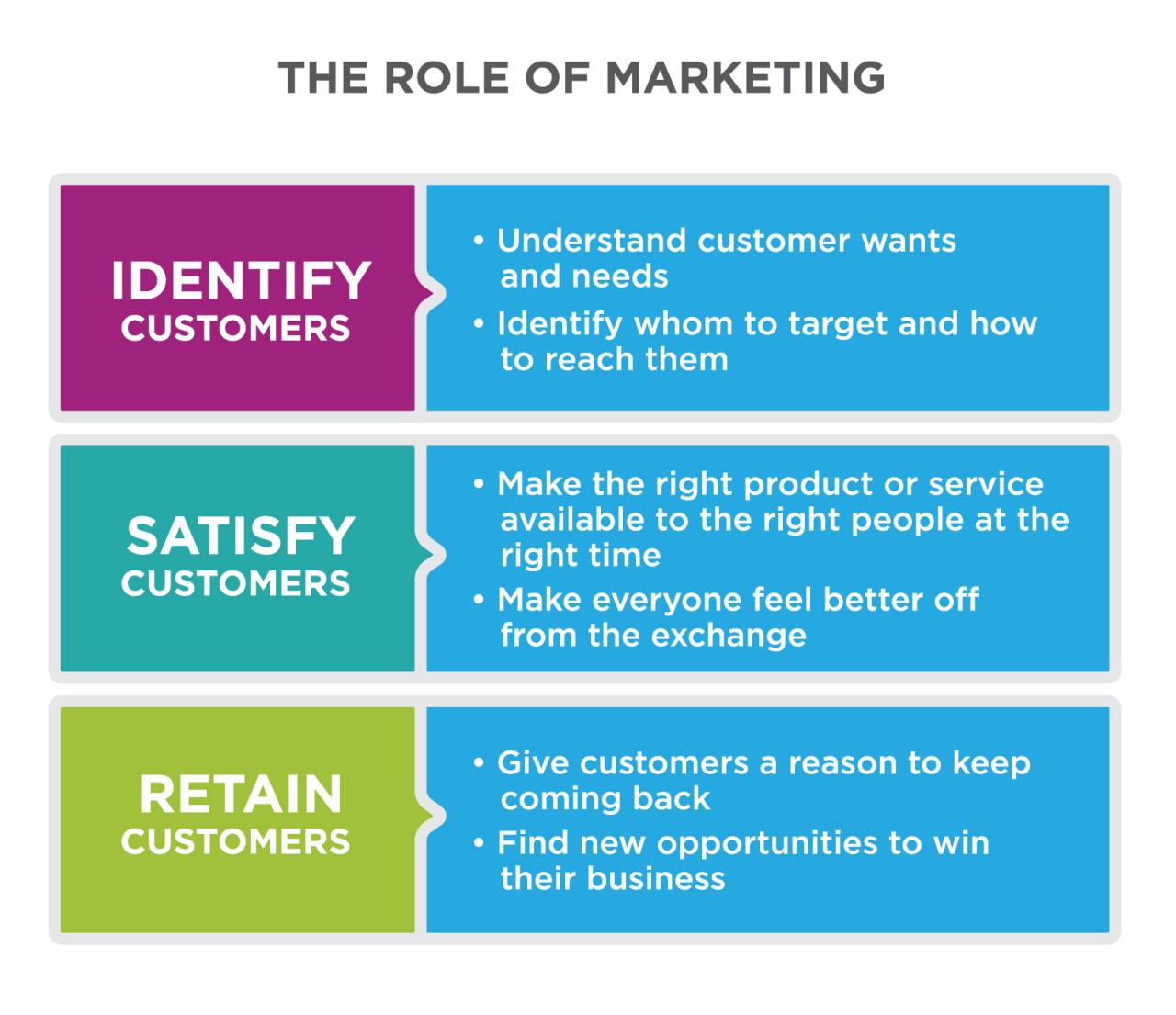

Comparison of Milk Types Used in Cheesemaking

Different types of milk offer unique characteristics that impact the final cheese. Here’s a comparison of common milk types used in cheesemaking:

| Milk Type | Fat Content (Approximate) | Protein Content (Approximate) | Flavor Profile | Typical Cheese Examples |

|---|---|---|---|---|

| Cow’s Milk | 3.25% – 4% | 3% – 3.5% | Versatile, can range from mild to robust depending on breed and processing. | Cheddar, Mozzarella, Gouda, Swiss |

| Goat’s Milk | 3.5% – 4.5% | 3% – 3.5% | Tangy, often with a slightly “goaty” flavor. | Chèvre, Feta, Crottin de Chavignol |

| Sheep’s Milk | 5% – 7% | 5% – 6% | Rich, complex, often with a slightly sweet or nutty taste. | Roquefort, Manchego, Pecorino Romano |

| Buffalo Milk | 7% – 8% | 4% – 4.5% | Very rich and creamy, slightly sweet. | Mozzarella di Bufala, Burrata |

The Culture Connection

Cheese cultures are the unsung heroes of cheesemaking, the microscopic powerhouses that transform milk into the diverse and delicious world of cheese we know and love. They are carefully selected strains of bacteria and molds, added to milk to kickstart the cheesemaking process. These cultures are the key to developing flavor, texture, and appearance.

What Cheese Cultures Do

Cheese cultures perform a multitude of essential functions during cheesemaking. Primarily, they convert lactose (milk sugar) into lactic acid. This acidification is crucial for several reasons: it helps to coagulate the milk proteins (casein), forming the curd; it inhibits the growth of undesirable bacteria that could spoil the cheese; and it contributes to the distinctive tangy flavors characteristic of many cheeses.

Beyond acidification, cultures also produce enzymes that break down proteins and fats, contributing to the development of complex flavors and textures over time. They can also create gas, leading to the formation of holes (eyes) in certain cheeses like Swiss. Finally, cultures influence the appearance of cheese, creating the rind or bloomy coating.

Types of Cheese Cultures

Different types of cheese cultures are used depending on the desired cheese type. They are generally categorized based on their optimal growth temperature.

- Mesophilic Cultures: These cultures thrive at moderate temperatures, typically between 20-35°C (68-95°F). They are used in a wide variety of cheeses, including cheddar, Colby, Monterey Jack, and many types of soft cheeses. Mesophilic cultures generally produce a moderate amount of acid and contribute a range of flavor compounds.

- Thermophilic Cultures: Thermophilic cultures prefer warmer temperatures, ranging from 30-45°C (86-113°F). They are employed in the production of cheeses like mozzarella, provolone, Swiss, and Parmesan. Thermophilic cultures produce acid more quickly than mesophilic cultures and are known for their ability to withstand higher cooking temperatures.

- Mold Cultures: These cultures are responsible for the distinctive rinds and internal structures of many cheeses. They include Penicillium molds, which are crucial for the development of blue cheeses ( Penicillium roqueforti) and bloomy-rind cheeses like Brie and Camembert ( Penicillium candidum or Penicillium camemberti). Mold cultures contribute to flavor, texture, and appearance.

- Propionic Cultures: These cultures, specifically Propionibacterium freudenreichii, are responsible for the characteristic large holes (eyes) and nutty flavor of Swiss cheese. They produce carbon dioxide gas as a byproduct of their metabolism, which creates the holes.

Common Bacteria and Molds in Cheesemaking

The following is a list of some of the most common cultures used in cheesemaking and the types of cheeses they influence.

- Lactococcus lactis subsp. lactis and cremoris: These are mesophilic lactic acid bacteria. They are used in cheddar, Colby, and many other hard and soft cheeses. They contribute to acid production and flavor development.

- Lactococcus lactis subsp. diacetylactis: This is a mesophilic culture. It produces diacetyl, which gives cheese a buttery flavor. It’s often used in combination with other cultures in cheeses like cheddar.

- Leuconostoc mesenteroides: This is a mesophilic culture that produces carbon dioxide and contributes to the texture and flavor of cheeses like Gouda and Havarti.

- Streptococcus thermophilus: This is a thermophilic lactic acid bacterium used in mozzarella, provolone, and Swiss cheese. It produces acid rapidly.

- Lactobacillus helveticus: This is a thermophilic lactic acid bacterium that contributes to the flavor of Swiss cheese and other hard cheeses.

- Penicillium roqueforti: This mold is essential for blue cheeses, creating the characteristic blue-green veins and pungent flavor. The mold requires specific conditions, including the presence of oxygen, to thrive inside the cheese. The image is a cross-section of a blue cheese wheel, showing the blue-green veins.

- Penicillium candidum or Penicillium camemberti: These molds are used for bloomy-rind cheeses like Brie and Camembert. They grow on the surface of the cheese, creating a white, edible rind. The image is a wheel of Brie cheese with a white, bloomy rind.

- Propionibacterium freudenreichii: This bacterium is used in Swiss cheese, producing carbon dioxide to create the characteristic holes (eyes) and contributing to the nutty flavor. The image is a close-up of a slice of Swiss cheese showing the large holes.

Coagulation and Curd Formation: Setting the Stage

Coagulation and curd formation are fundamental processes in cheesemaking, dictating the texture, moisture content, and overall characteristics of the final cheese product. Understanding these stages is crucial for controlling the cheese-making process and achieving the desired results. This section will delve into the intricacies of coagulation, exploring the roles of rennet and acid, and comparing acid-set and rennet-set cheese production.

The Process of Coagulation

Coagulation is the process by which milk transforms from a liquid state into a semi-solid gel, the curd. This transformation is primarily achieved through the action of enzymes (rennet) or acids. Both methods disrupt the casein micelles, the protein structures that give milk its opacity, causing them to aggregate and form a network that traps the milk solids and liquid.The two main agents used for coagulation are:* Rennet: Rennet is a complex enzyme, traditionally derived from the lining of the fourth stomach of young ruminant animals (calves, lambs, or kids).

Modern cheesemaking often utilizes microbial rennet or genetically modified rennet. The active enzyme in rennet is chymosin, which specifically cleaves a peptide bond in the kappa-casein protein that stabilizes the casein micelles. This destabilization causes the micelles to aggregate, forming a curd.

The primary reaction catalyzed by rennet can be summarized as: Kappa-Casein (soluble) → Para-Kappa-Casein (insoluble) + Caseinomacropeptide (soluble).

Acid

Acid coagulation can be achieved by adding acids directly to the milk (such as citric acid or vinegar) or by allowing the milk’s own lactic acid bacteria to produce acid through fermentation. As the pH of the milk decreases, the casein micelles become less stable and eventually aggregate, leading to curd formation.

Acid-Set Versus Rennet-Set Cheeses

The method of coagulation significantly impacts the cheese’s characteristics. Understanding the differences between acid-set and rennet-set cheeses is key to predicting and controlling the final product.Acid-set cheeses tend to be soft, fresh, and have a high moisture content. Examples include ricotta, cottage cheese, and some fresh goat cheeses. Rennet-set cheeses can range from soft to hard, with varying moisture levels, depending on the cheesemaking process.

Examples include cheddar, Swiss, and most aged cheeses.* Acid-Set Cheeses: These cheeses are coagulated primarily by the addition of acid. The acid denatures the casein proteins, causing them to clump together. The resulting curd is often fragile and has a fine texture.

- Characteristics: Tend to have a tangy flavor, a soft and sometimes grainy texture, and a high moisture content.

- Examples: Cottage cheese, ricotta, cream cheese, some fresh goat cheeses.

- Process: Acid is added to milk, either directly (e.g., adding vinegar) or indirectly (allowing lactic acid bacteria to produce acid). The milk is heated, and the acid causes the casein proteins to denature and coagulate.

Rennet-Set Cheeses

These cheeses rely on the enzyme rennet to coagulate the milk. Rennet cleaves a specific protein in the milk (kappa-casein), causing the casein micelles to aggregate. The resulting curd is generally firmer than acid-set curds.

- Characteristics: Can range from soft to hard, with varying moisture levels. They often have a more complex flavor profile and can be aged.

- Examples: Cheddar, Swiss, Gouda, Parmesan, Camembert.

- Process: Rennet is added to milk, which is then allowed to rest, typically at a specific temperature. The rennet enzyme acts on the casein proteins, causing the milk to coagulate into a solid curd.

Steps in Curd Formation: A Basic Cheese Recipe

The following table Artikels the typical steps involved in curd formation for a basic cheese recipe. This provides a simplified overview; specific recipes will vary depending on the type of cheese being made.

| Step | Description | Purpose | Considerations |

|---|---|---|---|

| Milk Preparation | Milk is heated to a specific temperature (e.g., 88-90°F / 31-32°C). | To create an optimal environment for rennet activity or acid production and to control the growth of unwanted bacteria. | Use pasteurized milk, unless raw milk is specifically desired and legal in your area. Ensure accurate temperature control. |

| Culture/Acid Addition (If Applicable) | If using a culture, it’s added at this stage to develop acidity. For acid-set cheeses, acid is added directly. | To initiate fermentation (in the case of cultures) or directly cause coagulation (in the case of added acid). | Use the correct type and amount of culture for the desired cheese. Carefully measure the acid to avoid over-acidification. |

| Rennet Addition | Rennet is added, diluted in cool, non-chlorinated water, and mixed gently. | To initiate the enzymatic reaction that causes the milk to coagulate. | Use the correct amount of rennet, as specified in the recipe. Mix gently to distribute evenly. |

| Coagulation/Setting | The milk is left undisturbed for a specific time, typically 30-90 minutes, until a firm curd forms. | To allow the rennet or acid to fully act on the milk proteins and form the curd. | Maintain a consistent temperature. The curd should be firm enough to make a clean break with a knife or spatula. |

Curd Handling

Now that we’ve seen how curds are formed, the next crucial phase is curd handling. This involves manipulating the curds to control moisture, texture, and ultimately, the final characteristics of the cheese. These steps are critical in determining the cheese’s final style, from the soft, creamy texture of a Brie to the firm, crumbly structure of a Cheddar.

Cutting the Curd

Cutting the curd is a pivotal step that directly impacts the moisture content of the cheese. The size to which the curd is cut determines the surface area exposed to whey. A larger surface area leads to greater moisture expulsion.The size of the cut is directly related to the final moisture content of the cheese. For example:

- Small curds (e.g., for Cheddar): Produce a drier cheese.

- Large curds (e.g., for some soft cheeses): Retain more moisture.

The cutting process itself involves using specialized curd knives, either vertical knives or horizontal harps, to slice the coagulated milk into the desired size. The cutting is typically done after the curd has sufficiently set, but before it becomes too firm.

Cooking the Curd

The cooking process further influences the cheese’s texture by controlling the moisture content and firming the curd. Heating the curds causes them to shrink and expel more whey, leading to a firmer cheese. The cooking temperature and duration vary greatly depending on the cheese style.The cooking process can involve several variations:

- Gentle Heating: Used for softer cheeses, this approach minimizes moisture loss. The temperature might only be raised a few degrees above the initial setting temperature.

- Higher Temperatures: Used for firmer cheeses, this promotes significant moisture expulsion. The curds may be heated to a temperature considerably higher than the initial setting temperature, often in a range from 32°C (90°F) to 54°C (130°F) or even higher, depending on the cheese type.

- Constant Temperature: Maintaining a consistent temperature during cooking can help achieve a uniform texture throughout the cheese.

- Gradual Temperature Increase: Slowly raising the temperature over a period allows for more controlled moisture expulsion and a more even curd firming.

The cooking process, coupled with the initial cutting size, gives cheesemakers precise control over the cheese’s final moisture content and texture. For example, a hard cheese like Parmesan will be cooked at a high temperature for a longer duration, resulting in a very firm, low-moisture curd.

Draining the Curd

Draining the curd is the process of separating the whey from the curds, further reducing moisture content and impacting the final cheese texture. The method and duration of draining are critical factors that contribute to the unique characteristics of each cheese type.There are various methods for draining, each suited to different cheese styles:

- Gentle Draining (for soft cheeses): This method involves allowing the whey to drain slowly, often using a cheesecloth-lined mold. The slow drainage helps retain more moisture, resulting in a soft, creamy texture.

- Direct Draining (for firmer cheeses): This involves removing the whey more rapidly, which can be done by using a colander, a draining vat, or by cutting the curd into smaller pieces to accelerate the process.

- Pressing (for hard cheeses): Pressing the curds under weight further expels whey and consolidates the curd mass. The pressure applied and the duration of pressing determine the final moisture content and density of the cheese. Cheddar and Gouda are typical examples of cheeses that are pressed.

- Whey Removal with Agitation: In some cases, such as in the production of some Swiss-style cheeses, the curds are agitated during draining. This helps to promote whey expulsion and creates a more uniform curd structure.

The draining process is often coupled with other steps, such as stirring or turning the curds, to ensure even whey removal. The chosen method, whether it is gentle draining, direct draining, or pressing, significantly influences the cheese’s final texture and moisture content.

Salting and Flavor Development: Enhancing the Taste

Salting is a crucial step in cheesemaking, playing a significant role in both the flavor and preservation of cheese. It’s more than just adding salt; it’s a carefully controlled process that influences the final characteristics of the cheese. Understanding the purpose and methods of salting is essential for any aspiring cheesemaker.

The Purpose of Salting in Cheesemaking

Salting serves several vital functions in cheesemaking, contributing significantly to the final product’s quality. Salt acts as a preservative, flavor enhancer, and also influences the texture and ripening process.

- Preservation: Salt inhibits the growth of undesirable bacteria and molds that can spoil the cheese. It does this by reducing the water activity (Aw) in the cheese, making it less hospitable for microbial growth. Lower water activity means less free water available for microorganisms to use.

- Flavor Development: Salt enhances the natural flavors of the cheese and can also contribute its own distinct salty taste. It interacts with the proteins and fats in the cheese, creating a more complex and desirable flavor profile. The amount of salt used and the method of salting directly influence the flavor intensity.

- Texture Modification: Salt affects the texture of the cheese by influencing the way the proteins interact. It can promote moisture loss, leading to a firmer texture. In some cheeses, salt helps to create a more elastic or pliable texture.

- Ripening Control: Salt influences the activity of enzymes and cultures involved in the ripening process. By slowing down or speeding up these processes, salt helps to control the rate at which the cheese matures and develops its characteristic flavors and textures. For example, in some bloomy rind cheeses, salt helps to regulate the growth of the mold on the surface.

Different Salting Methods

The choice of salting method depends on the type of cheese being made and the desired characteristics. The two most common methods are dry salting and brine salting.

- Dry Salting: This method involves rubbing salt directly onto the surface of the cheese or sprinkling it over the curds.

- Surface Salting: This is often used for cheeses with rinds, such as Cheddar or Gouda. The salt draws moisture from the cheese surface, creating a drier environment that inhibits the growth of unwanted microorganisms and encourages rind formation. The salt also penetrates the cheese over time.

- Curd Salting: This method is used for cheeses like Feta and some fresh cheeses. The salt is added directly to the curds before they are pressed or shaped. This ensures even distribution of salt throughout the cheese.

- Brine Salting: In this method, the cheese is submerged in a saltwater solution (brine) for a specific period.

- The concentration of the brine and the duration of salting depend on the cheese type. The salt penetrates the cheese from the outside in.

- Brine salting is often used for cheeses like Feta, Halloumi, and some blue cheeses.

- The brine solution may also contain other ingredients, such as calcium chloride, to aid in the cheese’s texture and preservation.

How Salt Affects Cheese Flavor and Preservation

Salt has a profound impact on both the flavor and the preservation of cheese. Its effects are complex and depend on several factors, including the type of salt, the salting method, and the cheese’s composition.

- Flavor: Salt directly contributes a salty taste to the cheese, but it also enhances the other flavors present. It can amplify the sweetness of the lactose, the nutty notes of aged cheeses, and the tanginess of the lactic acid produced by the cultures. The amount of salt and its distribution influence the intensity and complexity of the flavor profile.

- Preservation: Salt acts as a preservative by reducing the water activity (Aw) in the cheese. Microorganisms need water to survive and multiply; by binding the water, salt makes it unavailable to them. This helps to prevent the growth of spoilage bacteria and molds.

- Water Activity (Aw): Water activity is a measure of the amount of free water available in a substance. Salt lowers the water activity, making the cheese more stable and extending its shelf life. The lower the Aw, the less likely microorganisms are to grow.

For example, a cheese with an Aw of 0.95 will spoil much faster than a cheese with an Aw of 0.90. The Aw of a cheese is a critical factor in determining its safety and storage life.

- Microbial Control: Salt selectively inhibits the growth of undesirable microorganisms. It can slow down the activity of some enzymes and cultures, while allowing others to thrive. This selective action is crucial for controlling the ripening process and developing the desired flavor and texture characteristics.

- Salt Concentration: The concentration of salt in the cheese is a key factor in flavor and preservation. Higher salt concentrations generally result in a saltier taste and greater preservation, but can also affect the cheese’s texture and ripening. The ideal salt concentration varies depending on the cheese type.

Aging and Ripening: The Transformation Process

The aging and ripening process is where the magic of cheesemaking truly happens. It’s the stage where the carefully crafted curds transform into the diverse array of cheeses we know and love. This process, often taking weeks, months, or even years, is a complex interplay of enzymatic and microbial activity, significantly influencing the final flavor, texture, and aroma of the cheese.

The Influence of Aging on Cheese Characteristics

Aging is crucial in developing the characteristic traits of different cheese varieties. During this period, a series of biochemical reactions occur, transforming the initial curd into a product with unique sensory properties. These transformations are driven by enzymes from the starter cultures, added molds, and the cheese itself.The key characteristics influenced by aging include:* Flavor: The breakdown of proteins (proteolysis) and fats (lipolysis) during aging generates a wide range of flavor compounds.

These include amino acids, peptides, and volatile organic compounds, contributing to the complex flavor profiles found in aged cheeses.

Texture

The breakdown of proteins also affects the texture of the cheese. Proteolysis softens the cheese, leading to changes in firmness, elasticity, and creaminess. The rate and extent of proteolysis vary depending on the cheese type and aging conditions.

Aroma

The aroma of cheese is developed through the release of volatile compounds. These compounds originate from the breakdown of proteins and fats, and are influenced by the specific microbial activity and environmental conditions.

Appearance

The surface appearance of the cheese changes during aging. Some cheeses develop rinds, either naturally or through the application of cultures or washes. The color and texture of the rind contribute to the overall aesthetic appeal and sensory experience.

Environmental Conditions for Aging

Different cheese types require specific environments to age properly. Controlling temperature, humidity, and air circulation is critical for successful ripening. These conditions support the growth of desirable microorganisms and enzymatic activity, leading to the desired flavor and texture development.* Temperature: Temperature controls the rate of enzymatic reactions and microbial growth. Generally, lower temperatures slow down the aging process, while higher temperatures accelerate it.

Different cheese types require specific temperature ranges. For example, hard cheeses like cheddar are often aged at cooler temperatures (around 4-10°C/39-50°F), while softer cheeses may require slightly warmer temperatures.

Humidity

Humidity affects the moisture content of the cheese and the growth of surface molds and bacteria. High humidity prevents the cheese from drying out, while low humidity can lead to a dry, cracked surface. The ideal humidity levels vary depending on the cheese type.

Air Circulation

Proper air circulation is essential for maintaining consistent temperature and humidity throughout the aging room. It also helps to control the growth of unwanted molds and bacteria. Air circulation can be achieved through natural convection or the use of fans.

Specific Environments

Some cheese types require specialized environments. For example, blue cheeses are aged in rooms with controlled humidity and air circulation to encourage the growth ofPenicillium roqueforti* mold. Washed-rind cheeses are frequently washed with brine or other solutions to promote the growth of specific bacteria on the surface.

Common Ripening Agents and Their Impact

Ripening agents are the microorganisms and enzymes that drive the aging process. These agents break down proteins, fats, and lactose, creating the complex flavors, textures, and aromas characteristic of each cheese type.Here is a bullet-point list explaining the impact of common ripening agents:* Starter Cultures (e.g.,Lactococcus*,

-

Lactobacillus*)

These bacteria, added at the beginning of cheesemaking, primarily produce lactic acid, which lowers the pH and contributes to flavor. They also contribute enzymes that start the breakdown of proteins.

- Lactococcus* species are commonly used in cheddar and other hard cheeses, producing lactic acid that impacts the cheese’s acidity and flavor profile.

- Propionic Bacteria (e.g.,

- Molds (e.g.,

- Penicillium camemberti*), these molds grow on or within the cheese, breaking down proteins and fats. They contribute to the characteristic flavors and textures, such as the sharp, tangy flavor of blue cheese or the creamy texture of brie.

Propionibacterium freudenreichii*)

Found in Swiss-type cheeses, these bacteria ferment lactic acid, producing carbon dioxide, which creates the characteristic holes (eyes) in the cheese. They also contribute to a nutty, sweet flavor.

Penicillium* species)

Used in blue cheeses (*Penicillium roqueforti*) and bloomy-rind cheeses (*Penicillium candidum* and

Yeasts

Yeasts can contribute to the ripening of certain cheeses, particularly those with washed rinds. They often grow on the surface, creating a unique flavor profile.

Brevibacterium linens

This bacterium is used to develop the characteristic orange rind and pungent aroma of washed-rind cheeses. It contributes to a complex flavor and soft texture.

Common Cheesemaking Terms: A Glossary

Understanding cheesemaking terminology is crucial for both aspiring and experienced cheesemakers. This glossary defines some of the most frequently encountered terms, providing a foundation for comprehending the cheesemaking process. Mastery of these terms will improve communication and facilitate deeper understanding of cheese production.

Essential Cheesemaking Terms

Below are definitions of some of the key terms used in cheesemaking, along with examples of how to use them in a sentence.

- Affinage: This is the French term for the process of aging and ripening cheese. It involves carefully controlling the environment – temperature, humidity, and airflow – to develop the desired flavors, textures, and rinds.

- Bloomy Rind: This refers to the soft, edible rind that develops on cheeses like Brie and Camembert. It’s formed by the growth of specific molds, typically

-Penicillium candidum*, on the surface. - Coagulation: The process by which milk proteins clump together to form a solid mass, the curd. This is typically achieved through the addition of rennet or acid.

- Curd: The solid portion of milk that results from coagulation. This is the base material from which cheese is made.

- Culture: Specific strains of bacteria or molds added to milk to acidify it, develop flavor, and influence the cheese’s characteristics.

- Whey: The watery liquid that remains after the curd has been separated from the milk. It contains lactose, proteins, and minerals.

- Washed Rind: A type of cheese rind that is regularly washed with brine, alcohol, or other liquids during the aging process. This promotes the growth of specific bacteria, leading to a flavorful and often pungent rind.

- Rennet: An enzyme that causes milk to coagulate. It is traditionally derived from the stomach lining of young animals, but vegetarian and microbial rennets are also available.

“The cheesemaker’s skill in

-affinage* is what transforms a young curd into a complex and flavorful cheese.”

“The

-bloomy rind* of the Brie was perfectly white and slightly velvety, indicating optimal ripening.”

“Rennet is added to the milk to initiate

-coagulation*, setting the stage for curd formation.”

“The cheesemaker cut the

-curd* into small cubes to help release the whey.”

“The

-culture* added to the milk will determine the type of cheese produced, such as lactic or propionic.”

“The cheesemaker drained the

-whey* from the curds, saving it for potential use in animal feed.”

“The

-washed rind* of the cheese developed a characteristic orange hue and a strong aroma.”

“The cheesemaker used animal

-rennet* to coagulate the milk for cheddar.”

Affinage: The Art of Cheese Aging

Affinage is more than just storing cheese; it’s a carefully orchestrated process that shapes the final product. The

affineur* (cheese ager) controls the environment to encourage specific microbial activity and enzymatic reactions, leading to the development of complex flavors and textures.

The importance of affinage lies in its ability to transform a simple curd into a diverse range of cheese styles. Here’s why it’s so critical:

- Flavor Development: During affinage, enzymes break down proteins and fats, creating a wide array of flavor compounds. The type of culture used, the humidity, and the temperature all influence the final flavor profile. For example, in a Gruyère, aging in a humid cellar can lead to the development of nutty and earthy notes, while a drier environment might result in a more crystalline texture.

- Texture Transformation: Affinage alters the texture of cheese. Soft cheeses become creamy, while hard cheeses become firmer and more complex. The rind formation also plays a crucial role, contributing to both flavor and texture. The moisture content is carefully managed to impact the texture.

- Rind Formation: The rind is a critical component of many cheeses. Affinage encourages the growth of beneficial molds and bacteria on the surface, forming a protective layer and contributing to the cheese’s character. Washed-rind cheeses, for instance, are regularly treated with brine or other solutions to promote the growth of specific bacteria, developing a distinctive aroma and flavor.

The

-affineur* uses various techniques to control the affinage process. These can include:

- Temperature Control: Different cheeses require different temperatures for optimal ripening. For example, a Brie might ripen best at a cooler temperature than a washed-rind cheese.

- Humidity Control: Humidity influences the moisture content of the cheese, affecting its texture and the growth of surface molds and bacteria.

- Airflow Control: Proper airflow prevents the buildup of undesirable molds and helps to dry the surface of the cheese, encouraging rind formation.

- Turning and Brushing: Regularly turning the cheese ensures even ripening. Brushing the cheese can help to control rind development.

Cheese Types and Their Terminology

Understanding the diverse world of cheese requires familiarity with the terminology associated with different cheese families. This section explores how various cheese types are classified and the specific language used to describe their characteristics. We will delve into the nuances of cheese families and examine the vocabulary that helps us appreciate the unique qualities of each cheese.

Cheese Families and Their Terminology

Cheese is categorized into families based on factors like moisture content, texture, and the ripening process. This table provides an overview of common cheese families and associated terminology.

| Cheese Family | Key Characteristics | Typical Terminology | Examples |

|---|---|---|---|

| Fresh Cheeses | High moisture content; unripened; mild flavor. | Creamy, mild, tangy, spreadable, lactic. | Feta, ricotta, cottage cheese, queso fresco. |

| Soft-Ripened Cheeses | High moisture content; ripened from the outside in; bloomy rind. | Bloomy rind, creamy, runny, earthy, mushroomy. | Brie, Camembert, Saint-André. |

| Semi-Hard Cheeses | Moderate moisture content; various textures and flavors; often aged. | Buttery, nutty, sharp, firm, supple. | Gouda, Havarti, Monterey Jack. |

| Hard Cheeses | Low moisture content; often aged for extended periods; complex flavors. | Sharp, nutty, crystalline, crumbly, granular. | Cheddar, Parmesan, Gruyère. |

| Blue Cheeses | Ripened with blue mold; distinct flavor profile. | Pungent, salty, sharp, veined, creamy. | Roquefort, Gorgonzola, Stilton. |

| Washed-Rind Cheeses | Rind washed with brine, beer, or other liquids; strong aroma and flavor. | Earthy, pungent, meaty, sticky rind, bold. | Taleggio, Époisses, Limburger. |

Specific Terminology for Cheese Types

Different cheese types have their own specific vocabulary used to describe their characteristics. This vocabulary helps distinguish one cheese from another and appreciate their unique qualities. Let’s look at a few examples.

- Brie: The terminology used for Brie often includes descriptors like “bloomy rind,” referring to the white, edible mold on the surface. The interior is described as “creamy,” “runny,” or “buttery,” reflecting its texture. Flavor notes may include “mushroomy,” “earthy,” or “grassy,” depending on the aging process and milk source.

- Cheddar: Cheddar’s characteristics are described using terms such as “sharp,” indicating a high level of acidity, and “nutty,” referring to the flavors developed during aging. The texture is described as “firm” when young and becomes “crumbly” as it ages. Other descriptors can include “tangy,” “smooth,” or “crystalline” (referring to the small calcium lactate crystals that develop during aging).

- Parmesan: Parmesan is characterized by its “granular” texture, a result of its low moisture content and long aging period. Flavor descriptors include “nutty,” “salty,” and “fruity.” The cheese is often described as “hard” and “crystalline,” with visible calcium lactate crystals adding to its texture. The aging process allows for the development of complex flavors.

Troubleshooting: Addressing Common Issues

Making cheese is a rewarding journey, but it’s not without its challenges. Even experienced cheesemakers encounter problems from time to time. Understanding common issues and knowing how to address them is crucial for success. This section will delve into typical problems, using relevant cheesemaking terminology to help you diagnose and resolve them.

Off-Flavors: Identifying and Addressing Unwanted Tastes

Off-flavors can ruin a cheese, making it unpalatable. They often arise from issues with the milk, the cultures, or the cheesemaking process itself. Identifying the source is the first step toward a solution.

- Bitter Cheese: This can be caused by several factors. Excessive rennet can lead to bitter peptides, particularly in aged cheeses. High salt concentration, especially in the early stages, can also contribute. Another cause can be the use of wild or undesirable molds or bacteria. Addressing this involves careful rennet measurement, proper salting techniques, and ensuring a clean cheesemaking environment.

- Ammonia Taste: This often indicates excessive protein breakdown, frequently seen in aged cheeses. It’s often associated with cheeses that have been aged at too high a temperature or with insufficient humidity. The solution involves controlling aging conditions, ensuring proper ventilation, and adjusting the aging environment.

- Soapy Flavor: This can be due to lipolysis, the breakdown of fats, often caused by enzymes naturally present in the milk. Milk handling, especially excessive agitation, can also contribute. Pasteurization can help deactivate these enzymes, but it also alters the milk’s characteristics. Proper milk handling and culture selection are key to preventing this.

- Rancid Flavor: This is caused by the breakdown of fats into free fatty acids. It’s often related to poor milk quality, bacterial contamination, or improper storage. Ensuring fresh milk, maintaining strict hygiene, and controlling storage temperatures are crucial to prevent this issue.

Mold and Surface Issues: Managing Unwanted Growth

Mold is essential for many cheeses, but unwanted mold or other surface issues can detract from the final product.

- Undesirable Mold Growth: This can be due to a variety of molds that are not part of the intended cheese profile. Improper humidity, temperature, or a contaminated environment can encourage these growths. Controlling the aging environment, using starter cultures that dominate the surface, and ensuring proper cleaning are key.

- Slime Formation: This indicates unwanted bacterial growth on the cheese surface. It often happens in environments with high humidity and poor air circulation. Controlling the aging environment and using proper washing techniques, if applicable to the cheese type, can help.

- Cracking and Drying: This occurs when the cheese surface loses moisture too quickly. This can happen if the aging environment is too dry or the cheese isn’t properly sealed. Adjusting humidity levels and using appropriate rind treatments, like waxing or oiling, can help.

Texture Problems: Achieving the Desired Consistency

Texture is a critical aspect of cheese. Issues with texture can make a cheese unappealing.

- Mealy or Gritty Texture: This often results from excessive acid development or insufficient moisture. Careful control of the ripening process, using the correct starter cultures, and adjusting moisture levels are key to resolving this.

- Rubbery Texture: This can be caused by overworking the curds, insufficient whey drainage, or excessive acidity. Gentle curd handling, proper pressing techniques, and pH control are essential.

- Weak or Soft Texture: This can be due to insufficient calcium in the milk, excessive moisture, or improper aging conditions. Adding calcium chloride to the milk, controlling moisture levels, and adjusting the aging environment can help.

Common Cheesemaking Problems and Solutions:

- Problem: Bitter Cheese. Solution: Reduce rennet, control salting, ensure a clean environment.

- Problem: Ammonia Taste. Solution: Control aging temperature and humidity.

- Problem: Undesirable Mold Growth. Solution: Control the aging environment, use starter cultures, and ensure proper cleaning.

- Problem: Mealy Texture. Solution: Control ripening, use correct starter cultures, and adjust moisture.

Last Recap

So, there you have it – a comprehensive introduction to the core vocabulary of cheesemaking. From understanding the role of cultures to mastering the art of affinage, you’re now equipped with the essential terminology to explore the delicious world of cheese. Remember, the more you learn, the more rewarding your cheesemaking experience will be. Now, go forth and experiment, and may your cheese creations be as delightful as the language that describes them!