Embark on a delightful journey into the world of cheesemaking with How to Make a Traditional Caerphilly Cheese. This classic Welsh cheese, known for its crumbly texture and refreshing tang, offers a rewarding experience for both novice and experienced cheesemakers. From its humble beginnings in Caerphilly, this cheese has captivated palates for generations. Learn the secrets behind crafting this iconic cheese from the comfort of your own kitchen.

This guide will walk you through every stage, from selecting the right ingredients and equipment to mastering the crucial steps of milk preparation, curd handling, pressing, and aging. Discover the nuances of flavor development, troubleshoot common challenges, and explore exciting variations to personalize your Caerphilly creation. We’ll also cover serving suggestions and perfect pairings to elevate your cheese experience.

Introduction to Caerphilly Cheese

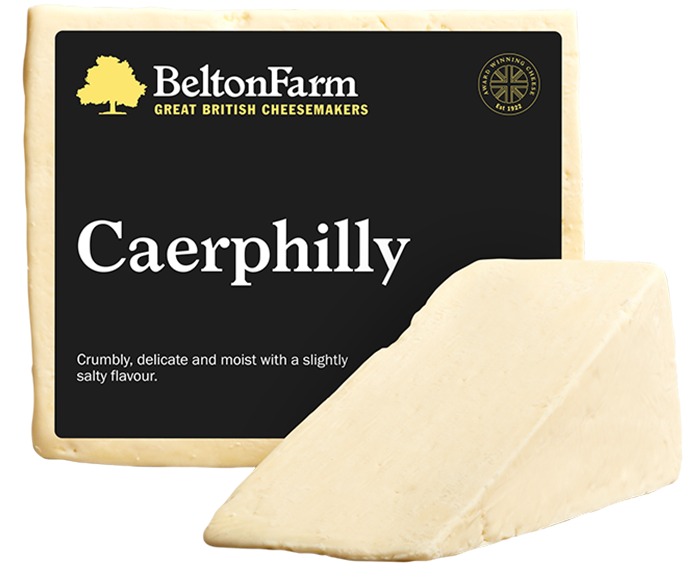

Caerphilly cheese, a crumbly and mild Welsh cheese, offers a delightful experience for cheese lovers. Its history and distinctive characteristics make it a unique culinary treasure. This guide will delve into the origins, characteristics, and variations of this beloved cheese.

History and Origins

Caerphilly cheese originates from the town of Caerphilly in South Wales. It was traditionally produced to feed coal miners in the region during the late 19th and early 20th centuries. The cheese’s high salt content helped replenish electrolytes lost by the miners during their work. Its crumbly texture also made it easy to transport and eat underground. The cheese became so popular that its production spread beyond Caerphilly, and it became a staple in many Welsh homes and beyond.

Characteristics of Traditional Caerphilly Cheese

Traditional Caerphilly cheese is easily identifiable by its distinctive features. These characteristics contribute to its unique taste and texture.

- Texture: Caerphilly is known for its moist, open, and crumbly texture. This crumbly nature is a key feature, making it easy to break apart.

- Flavor Profile: The flavor is generally mild, fresh, and slightly salty. It has a clean, lactic taste with a hint of citrus. As the cheese ages, the flavor can become more complex and slightly tangy.

- Appearance: The cheese typically has a white or off-white color. It is usually formed into a cylindrical shape with a natural rind, which is often covered in a light mold.

Regional Variations of Caerphilly Cheese

While the core characteristics of Caerphilly remain consistent, regional variations exist, influenced by factors like the milk source and production methods.

- Traditional Welsh Caerphilly: This is the original style, made with cow’s milk and characterized by its crumbly texture and mild, salty flavor. The cheese is usually made in a cylindrical shape and aged for a relatively short period.

- Modern Caerphilly: Over time, the production of Caerphilly has evolved. Some modern versions use different milk sources or production techniques, which can slightly alter the texture and flavor. For instance, some cheesemakers might add a small amount of cream to increase the fat content and create a smoother texture.

- Other Variations: Some cheesemakers experiment with different aging processes or flavor additions. For example, some Caerphilly cheeses are now available with added herbs or spices, or even smoked.

Essential Equipment and Ingredients

Making Caerphilly cheese at home requires specific equipment and ingredients. Having the right tools and supplies ensures a successful cheesemaking process and helps achieve the desired texture and flavor. Careful selection and preparation of these elements are crucial for producing authentic Caerphilly.

Equipment

The following equipment is essential for making Caerphilly cheese. This equipment facilitates each stage of the cheesemaking process, from heating the milk to pressing the final cheese. The choice of materials and the quality of the equipment impact the final product.

| Equipment | Function | Details | Example |

|---|---|---|---|

| Large Stainless Steel Pot | Heating and holding milk. | Should be non-reactive and large enough to accommodate the milk volume, allowing for ample space to prevent spills during heating and stirring. A heavy-bottomed pot is ideal for even heat distribution. | A 10-12 liter pot is suitable for making a single Caerphilly cheese using approximately 8 liters of milk. |

| Thermometer | Monitoring milk temperature. | Essential for accurate temperature control during various stages of cheesemaking, such as heating, adding cultures, and rennet. A digital thermometer provides precise readings. | A digital thermometer with a probe allows for easy monitoring of milk temperature. |

| Cheese Mold | Shaping the cheese. | The mold determines the shape and size of the Caerphilly. Traditional molds are cylindrical and made of food-grade plastic or stainless steel. The mold should have drainage holes to allow whey to escape. | A cylindrical mold, approximately 15-20 cm in diameter and 8-10 cm high, is commonly used for Caerphilly. |

| Cheese Press | Pressing the cheese. | Applies pressure to the cheese to expel whey and shape the cheese. A simple press can be constructed using weights or a more sophisticated press with adjustable pressure. | A cheese press using weights, such as bricks or water-filled containers, to apply pressure. A press capable of applying 10-15 pounds of pressure is sufficient. |

| Cheesecloth | Filtering and draining whey. | Used to line the cheese mold and aid in whey drainage. Cheesecloth helps to create a smooth surface and prevents the cheese from sticking to the mold. | Several layers of cheesecloth are typically used to line the mold. |

| Cutting Utensil | Cutting the curd. | A long knife or curd knife is needed to cut the curd into the correct size. | A long, thin-bladed knife or a curd knife specifically designed for cheesemaking is suitable. |

| Large Spoon or Ladle | Stirring and transferring curd. | Used for gently stirring the milk during heating and for transferring the curd into the mold. | A large, slotted spoon is helpful for stirring and draining the whey from the curd. |

Ingredients

The ingredients used in Caerphilly cheese directly influence its flavor, texture, and overall quality. Using high-quality ingredients and precise measurements is critical for achieving the characteristic taste and consistency of Caerphilly.

- Milk: The type of milk significantly impacts the cheese’s flavor and texture. Traditionally, Caerphilly is made with cow’s milk. Fresh, pasteurized milk is typically used, but unpasteurized milk can also be used, though it requires specific handling and may necessitate additional safety measures. The fat content of the milk will influence the richness of the cheese.

- Cheese Cultures: These are crucial for developing the cheese’s flavor and texture. A mesophilic culture is typically used. The culture ferments the lactose (milk sugar) into lactic acid, which helps to acidify the milk and set the curd.

- Rennet: This enzyme is used to coagulate the milk, forming the curd. Rennet can be animal-based (from the stomach of young animals), vegetable-based, or microbial. The type and amount of rennet used affect the curd formation and the final cheese texture.

- Salt: Salt plays several roles in cheesemaking. It helps to control moisture content, flavor development, and inhibits undesirable bacteria. Salt can be added directly to the curd or used in a brine bath for the cheese.

The Cheesemaking Process

Now that you have your ingredients and equipment ready, it’s time to dive into the heart of cheesemaking: the process itself. This is where the magic happens, transforming milk into the delicious Caerphilly cheese we all love. Patience and precision are key here, so let’s get started.

Milk Preparation

Proper milk preparation is crucial for a successful Caerphilly. This involves ensuring the milk is safe and at the correct temperature for the cultures and rennet to work effectively.The process of preparing the milk for cheesemaking includes:* Pasteurization (If Applicable): If using raw milk, you might choose to pasteurize it. Pasteurization involves heating the milk to a specific temperature for a set time to eliminate harmful bacteria.

The typical parameters for cheesemaking are 63°C (145°F) for 30 minutes, or 72°C (161°F) for 15 seconds, followed by rapid cooling. This process can slightly alter the flavor of the final cheese, but it significantly enhances its safety.

Cooling

After pasteurization (or if using already pasteurized milk), cool the milk down to the target temperature for adding cultures. This is usually around 30-32°C (86-90°F). Use a clean container and a thermometer to monitor the temperature. A cold water bath or a cheese vat with a cooling system can be used to speed up the process.

Checking Acidity

Before adding cultures, it is important to check the milk’s acidity. The ideal pH range for Caerphilly cheese is around 6.5.

Adding Cultures and Rennet

This step introduces the beneficial bacteria and enzymes that will transform the milk into cheese. Accurate measurements and careful mixing are essential.The steps for adding cultures and rennet are:* Adding the Culture: Add the mesophilic starter culture to the milk. The amount will depend on the specific culture you are using; follow the manufacturer’s instructions. Sprinkle the culture evenly over the surface of the milk and allow it to rehydrate for a few minutes.

Mixing the Culture

Gently stir the milk for about 2-3 minutes to ensure the culture is evenly distributed. Avoid vigorous stirring, which can disrupt the milk’s proteins.

Adding the Rennet

Once the culture is well mixed, add the rennet. Rennet is an enzyme that causes the milk to coagulate, forming the curd. The amount of rennet depends on its strength and the manufacturer’s instructions, but typically, a small amount is sufficient. Dilute the rennet in a small amount of cool, non-chlorinated water before adding it to the milk.

Mixing the Rennet

Gently stir the milk for about 1 minute to distribute the rennet evenly.

Allowing the Milk to Set

Cover the vat and allow the milk to sit undisturbed. The time required for the milk to coagulate will vary depending on the rennet and milk’s properties, but typically, it takes about 45-60 minutes. The milk is set when it forms a firm, custard-like consistency. You can test for the “clean break” by inserting a clean knife or spatula into the curd and gently lifting it.

If the curd breaks cleanly, leaving a clear whey, it is ready to be cut.

Cutting and Stirring the Curd

Cutting and stirring the curd is a critical stage that determines the moisture content and texture of the final cheese. This requires precise timing and gentle handling.The process involves:* Cutting the Curd: Once the milk has set, it is time to cut the curd. Use a long knife or curd cutter to make even cuts. First, cut the curd vertically in a grid pattern, creating 1-inch cubes.

Then, allow the curds to rest for 5-10 minutes to allow the whey to begin to separate.

Stirring the Curd

Gently stir the curds for about 30-45 minutes. The goal is to prevent the curds from matting together and to promote whey expulsion. As you stir, the curds will gradually shrink and become firmer.

Maintaining Temperature

Throughout the cutting and stirring process, maintain the milk temperature at around 30-32°C (86-90°F).

Draining and Molding the Curd

Draining the whey and molding the curd into the characteristic Caerphilly shape is the next stage. This process influences the cheese’s final moisture content and shape.The process includes:* Draining the Whey: After stirring, allow the curds to settle. Carefully drain off the whey. You can use a cheesecloth-lined colander or a cheese vat with a draining system.

Salting the Curd (Optional)

Some cheesemakers salt the curds at this stage to enhance flavor and help control moisture. If you choose to salt, add the salt evenly and gently mix it into the curds.

Molding the Curd

Transfer the curds to cheese molds. These molds are typically cylindrical and have drainage holes. Fill the molds evenly, ensuring there are no air pockets.

Pressing the Cheese

Pressing the cheese is crucial for expelling more whey and developing the desired texture. The pressure applied and the duration of pressing influence the final cheese characteristics.The pressing process involves several stages:* Initial Pressing: Place the filled molds in a cheese press. Apply a light pressure, typically around 5-10 psi, for the first hour. This allows the curds to knit together.

Increasing Pressure

Gradually increase the pressure over the next few hours. A typical pressing schedule for Caerphilly is:

1 hour at 5-10 psi

3 hours at 10-15 psi

12 hours at 15-20 psi

Turning the Cheese

During the pressing, turn the cheese over in the molds several times. This ensures even whey expulsion and prevents uneven shapes.

Removing from the Press

After pressing, remove the cheese from the molds.

Aging Process

Aging is where the Caerphilly cheese develops its characteristic flavors and textures. The environment plays a crucial role in this process.The aging process involves:* Temperature: The ideal aging temperature for Caerphilly cheese is between 10-13°C (50-55°F).

Humidity

Maintain a high humidity level, around 85-90%, to prevent the cheese from drying out. A cheese cave or a specially designed aging room is ideal.

Turning

Turn the cheese regularly, ideally every day or every other day, for the first few weeks. This promotes even aging and prevents mold growth on one side.

Monitoring

Monitor the cheese for mold growth. A white or light blue mold is typical and desirable for Caerphilly. If undesirable molds appear, brush them off with a clean brush.

Aging Time

Caerphilly cheese typically ages for 2-4 weeks, but this can vary depending on the desired flavor and texture.

Troubleshooting Common Problems

Making Caerphilly cheese, like any cheesemaking endeavor, can sometimes present challenges. Understanding potential problems and how to address them is crucial for consistently producing a high-quality cheese. This section will cover common issues that may arise during the cheesemaking process, offering solutions and preventative measures to ensure success.

Curdling Problems

Curdling issues are frequently encountered during the cheesemaking process and can stem from various factors. These problems can manifest in several ways, such as a weak or slow curd formation, a curd that is too soft, or a curd that is too firm.The primary causes of curdling problems include:

- Temperature Inconsistencies: Maintaining the correct temperature throughout the process is critical. Too low a temperature can result in slow curdling, while too high a temperature can lead to a curd that is too firm and difficult to handle.

- Culture Issues: The type and activity of the starter culture significantly impact curd formation. A culture that is not active or is past its expiration date may not produce enough acid to properly coagulate the milk.

- Rennet Problems: Rennet is the enzyme responsible for coagulating the milk proteins. Using too little rennet will result in a weak curd, while using too much can lead to a rubbery texture. The rennet’s strength and storage conditions also affect its performance.

- Milk Quality: The quality of the milk itself plays a crucial role. Milk that is not fresh, has been overheated, or has been treated with antibiotics can interfere with curd formation.

To address curdling problems, consider the following solutions:

- Temperature Adjustments: Monitor and adjust the temperature of the milk according to the recipe. A stable temperature is essential for optimal curd formation.

- Culture Verification: Ensure the starter culture is fresh and active. Check the expiration date and store the culture properly. Consider using a new batch of culture if the current one is suspected of being inactive.

- Rennet Dosage: Accurately measure the rennet according to the recipe. If the curd is weak, slightly increase the rennet amount in the next batch. If the curd is too firm, reduce the rennet. Always use rennet within its expiration date.

- Milk Sourcing: Use fresh, high-quality milk. Avoid milk that has been treated with antibiotics or has been stored for an extended period. Pasteurization, if used, should be performed at the recommended temperature to avoid damaging milk proteins.

Undesirable Flavors

Undesirable flavors can ruin the final product. These flavors often arise from contamination, poor sanitation, or issues during the aging process. Understanding the sources of these flavors is the first step in preventing them.Common undesirable flavors include:

- Bitter Flavor: This can be caused by excessive rennet, high salt levels, or the presence of certain bacteria.

- Ammonia Flavor: This often indicates excessive protein breakdown, which can occur if the cheese is aged at too high a temperature or for too long.

- Sour Flavor: This can result from over-acidification, typically due to excessive starter culture activity or prolonged fermentation.

- Off-Flavors: Various off-flavors can arise from mold growth, bacterial contamination, or the use of poor-quality ingredients.

To minimize undesirable flavors, take these actions:

- Rennet Management: Use the correct amount of rennet and avoid over-renneting.

- Salting: Follow the recipe for salt levels. Too much salt can create bitterness.

- Aging Conditions: Control the temperature and humidity during aging. Proper conditions are essential to prevent excessive protein breakdown.

- Sanitation Practices: Thoroughly sanitize all equipment and utensils to prevent contamination.

- Ingredient Quality: Use fresh, high-quality milk and other ingredients.

Mold Growth on Cheese

Mold growth is a common concern during cheese aging, but it can be managed with proper techniques. While some molds are desirable (e.g., in blue cheese), others can spoil the cheese and pose health risks.Understanding and preventing unwanted mold growth involves:

- Identifying Unwanted Molds: Unwanted molds can appear as fuzzy, discolored patches on the cheese surface. They can range in color from green and blue to black and red.

- Controlling Humidity: Mold thrives in humid environments. Maintain the recommended humidity level in the aging room.

- Temperature Control: Keep the aging room at the correct temperature. This can slow mold growth.

- Surface Treatment: Regularly wash the cheese surface with a brine solution or a mold-inhibiting wash. This helps to control unwanted mold.

- Air Circulation: Ensure good air circulation in the aging room to prevent moisture buildup and mold growth.

If mold is detected:

- Identification: Determine if the mold is desirable or undesirable.

- Removal: If the mold is undesirable, carefully trim it off the cheese surface, removing at least an inch around the affected area.

- Surface Treatment: After removing the mold, treat the surface with a brine wash to prevent regrowth.

- Monitoring: Monitor the cheese regularly for any signs of recurring mold.

Sanitation and its Impact on the Final Product

Sanitation is paramount in cheesemaking. It directly impacts the flavor, texture, and safety of the final product. Proper sanitation prevents contamination from unwanted bacteria and molds.The importance of sanitation includes:

- Preventing Contamination: Sanitizing all equipment and surfaces eliminates potential sources of contamination.

- Maintaining Quality: Sanitation helps to ensure the cheese develops the intended flavors and textures.

- Ensuring Safety: Sanitation is critical for preventing the growth of harmful bacteria that could pose a health risk.

Implementing sanitation protocols:

- Cleaning: Thoroughly clean all equipment and utensils with hot, soapy water.

- Sanitizing: After cleaning, sanitize all equipment with a food-grade sanitizer. Follow the manufacturer’s instructions for dilution and contact time.

- Rinsing: Rinse all sanitized equipment with potable water to remove any sanitizer residue.

- Storage: Store all sanitized equipment in a clean, dry place to prevent recontamination.

- Personal Hygiene: Practice good personal hygiene, including washing hands thoroughly before starting the cheesemaking process.

Flavor Development and Aging

The aging process is crucial for transforming the fresh, mild curds of Caerphilly into the complex, tangy cheese we know and love. During this time, a multitude of biochemical reactions occur, driven by enzymes and microorganisms, that sculpt the cheese’s flavor, texture, and aroma. This section will delve into the specifics of how to age your Caerphilly to perfection.

The Role of Aging

Aging allows Caerphilly to develop its characteristic flavor profile. The fresh curds, initially bland, are transformed by enzymatic breakdown of proteins and fats. This process, primarily carried out by naturally occurring molds and bacteria, creates the characteristic tangy, slightly acidic, and often mushroomy flavors. The longer the cheese ages, the more pronounced these flavors become, alongside changes in texture.

Ideal Aging Environment

Creating the right environment is essential for successful aging. This involves controlling temperature, humidity, and ventilation.

- Temperature: The ideal aging temperature for Caerphilly is between 10-13°C (50-55°F). Colder temperatures will slow down the aging process, while warmer temperatures can lead to undesirable bacterial growth and off-flavors. A consistent temperature is key; fluctuations should be minimized.

- Humidity: Maintaining high humidity, around 85-90%, is critical to prevent the cheese from drying out. Dry air can lead to a hard, cracked rind and a crumbly interior. This humidity level encourages the growth of the desired molds and bacteria on the surface. You can monitor humidity using a hygrometer.

- Ventilation: Good ventilation is also important. It prevents the buildup of undesirable gases and helps control mold growth. Air circulation helps to dry the rind, creating a favorable environment for the Penicillium candidum mold to develop. You can achieve ventilation by using a cheese cave, a dedicated refrigerator, or a well-ventilated room.

Monitoring the Aging Process

Regular monitoring is vital to ensure your Caerphilly develops as intended. This involves observing the cheese visually and, after a few weeks, tasting it.

- Visual Inspection: Initially, the rind will be quite thin and may appear slightly moist. As the cheese ages, a white, bloomy rind will develop. This is the characteristic Penicillium candidum mold. Look for a uniform, healthy white bloom. Discoloration, such as blue or green patches, can indicate unwanted mold growth and should be addressed.

- Tactile Assessment: Gently press the cheese to assess its texture. It should gradually soften from the outside in. Avoid pressing too hard, as this can damage the rind.

- Tasting: Begin tasting the cheese after approximately 2-3 weeks of aging. Taste small pieces regularly to monitor flavor development.

Flavor Changes Over Time

The flavor of Caerphilly evolves over time, as illustrated in the following table. The timeframe provided is an estimate, as aging speed depends on environmental factors.

| Aging Time | Appearance | Texture | Flavor Profile |

|---|---|---|---|

| 2-3 Weeks | Thin, slightly moist rind; white bloom beginning to develop. | Slightly firm, with a creamy interior. | Mild, lactic, slightly acidic, fresh milk notes. |

| 4-6 Weeks | Thickening white rind; more pronounced bloom. | Softer, with a slightly chalky interior. | Tangy, more pronounced acidity, developing mushroomy notes. |

| 8-12 Weeks | Mature white rind; may show some slight yellowing. | Creamy, almost melting near the rind, crumbly in the center. | Complex, pronounced tang, earthy, mushroomy, with a lingering finish. |

| 12+ Weeks | Rind may become slightly more wrinkled. | Very soft and creamy, potentially runny near the rind. | Intense flavors, with a strong tang and complex, savory notes. The cheese may also become more ammoniated. |

Variations and Adaptations

Caerphilly cheese, while traditionally made in a specific way, offers exciting opportunities for experimentation and adaptation. The beauty of home cheesemaking lies in the ability to tailor recipes to personal preferences and available resources. This section explores ways to modify the classic Caerphilly recipe, offering both flavor enhancements and practical adjustments for home cheesemakers.

Flavored Caerphilly Variations

Adding flavors to Caerphilly cheese can create a diverse range of culinary experiences. Incorporating ingredients during the cheesemaking process or after the cheese has aged allows for unique flavor profiles.

- Herb-Infused Caerphilly: Fresh herbs like chives, dill, or parsley can be added to the curd before draining and pressing. This imparts a fresh, aromatic quality to the cheese. The amount of herbs used can be adjusted based on preference, typically starting with a small amount (e.g., 1-2 tablespoons per gallon of milk) and increasing to taste.

- Spice-Infused Caerphilly: Incorporating spices like black pepper, garlic powder, or paprika into the curd adds depth and complexity. Experiment with different spice combinations to find your favorite flavor profile. Start with small amounts (e.g., 1/2 teaspoon per gallon of milk) and adjust to taste.

- Vegetable-Infused Caerphilly: Finely diced vegetables, such as roasted red peppers or sun-dried tomatoes, can be added to the curd. This adds both flavor and texture. Ensure the vegetables are well-drained to prevent excess moisture from affecting the cheese’s consistency.

- Beer-Washed Caerphilly: After the cheese has been formed, the rind can be washed with beer during the aging process. This can add interesting flavors and encourages the growth of certain molds, resulting in a unique rind and flavor profile. The choice of beer will significantly influence the final taste; lighter beers will impart subtler flavors, while darker beers will add more robust notes.

Recipe Adaptations for Different Milk Types

The milk source significantly impacts the final cheese’s characteristics, including flavor, texture, and yield. While cow’s milk is traditional, Caerphilly can be successfully made with other milk types.

Recipe Adaptations for Different Milk Types:

Goat Milk: Goat milk Caerphilly tends to be tangier and slightly drier than cow’s milk Caerphilly.

- Reduce the amount of rennet slightly to prevent over-firming.

- Consider adding a small amount of cream (e.g., 1 cup per gallon of milk) to increase the fat content and improve the texture.

Sheep Milk: Sheep milk Caerphilly will have a richer, more complex flavor.

- Sheep milk has a higher fat content than cow’s milk, so the recipe can be followed as is.

- Monitor the acidity closely, as sheep milk cheese can acidify more quickly.

Buffalo Milk: Buffalo milk is very high in fat, resulting in a creamy cheese.

- Reduce the amount of rennet slightly.

- Be prepared for a higher yield of cheese.

Scaling Down the Recipe

Home cheesemakers often work with smaller quantities of milk than commercial producers. Scaling down the Caerphilly recipe is straightforward. The key is to maintain the correct ratios of ingredients.

- Reduce all ingredient quantities proportionally: If the original recipe calls for 1 gallon of milk, and you want to make cheese with 1 quart of milk, divide all ingredient amounts by 4.

- Adjust pressing times: Smaller cheeses will require shorter pressing times. Monitor the cheese closely and adjust the pressing time based on the observed firmness.

- Maintain temperature control: Accurate temperature control is crucial, regardless of the scale. Use a reliable thermometer and maintain the recommended temperatures throughout the cheesemaking process.

Serving and Pairing Caerphilly Cheese

Now that you’ve put in the effort to craft your own Caerphilly, the fun part begins: enjoying it! This section will guide you through the best ways to serve and appreciate your homemade cheese, from the perfect accompaniments to the ideal beverage pairings. We’ll also explore presentation ideas to make your Caerphilly a star at any gathering.

Serving Caerphilly: Presentation and Accompaniments

Serving Caerphilly is all about highlighting its delicate flavor and texture. A well-chosen presentation can elevate the experience. Consider these serving suggestions and accompaniments to complement the cheese:

- Temperature: Allow the cheese to come to room temperature (about 30-60 minutes) before serving. This allows the flavors to fully develop and the texture to soften slightly.

- Cutting: Caerphilly is often served in wedges or slices. Use a cheese knife or wire cutter to avoid crumbling the cheese. A thin, sharp knife works best.

- Accompaniments: The salty, lactic tang of Caerphilly pairs beautifully with a variety of accompaniments. Consider:

- Crackers and Bread: Choose neutral-flavored crackers or crusty bread to avoid overpowering the cheese.

- Fruits: Fresh, seasonal fruits like apples, pears, grapes, and figs offer a delightful contrast in sweetness and texture.

- Preserves and Chutneys: A dollop of fig jam, quince paste, or a tangy chutney can provide a welcome counterpoint to the saltiness.

- Nuts: Walnuts, almonds, or pecans add a crunchy element and nutty flavor that complements the cheese.

- Honey: A drizzle of honey, particularly a wildflower or acacia honey, can enhance the cheese’s sweetness and complexity.

- Presentation: Arrange your Caerphilly on a cheese board or serving platter. Consider the following:

- Variety: Include a selection of accompaniments to offer a range of flavor profiles.

- Visual Appeal: Arrange the cheese and accompaniments attractively, using color and texture to create visual interest.

- Labels: Label each cheese and accompaniment for your guests.

Pairing Caerphilly with Food and Drink

Finding the perfect pairings for Caerphilly is crucial to enhance the tasting experience. The cheese’s characteristics influence the ideal food and drink matches.

- Food Pairings:

- Apples: The crisp sweetness of apples offers a balanced contrast to the cheese’s saltiness.

- Pears: Similar to apples, pears provide a juicy and subtly sweet counterpoint.

- Crusty Bread: The simple flavors of crusty bread allow the cheese’s taste to shine through.

- Pickles: The acidity and tang of pickles cut through the richness of the cheese.

- Charcuterie: Caerphilly pairs well with cured meats like prosciutto or salami, where the fat content balances the saltiness of the cheese.

- Drink Pairings:

- Cider: The crispness and slight sweetness of a dry cider complement the cheese’s flavor.

- Light-Bodied White Wines: Sauvignon Blanc or Pinot Grigio are excellent choices. Their acidity cuts through the richness of the cheese.

- Dry Rosé: The refreshing qualities of a dry rosé provide a delightful pairing.

- English Ales: A traditional English ale, with its malty notes, can complement the cheese’s flavors.

- Sparkling Wine: Champagne or Prosecco’s effervescence and acidity cleanse the palate.

Illustration: A Caerphilly Cheese Board

Imagine a rustic wooden cheese board, artfully arranged with a selection of culinary delights. At the center, a wedge of creamy, ivory-colored Caerphilly cheese takes pride of place. Its slightly uneven surface hints at its handmade nature. To the left, a cluster of ruby-red grapes spills over the edge of the board, their glistening skins promising a burst of sweetness.

Beside the grapes, thinly sliced green apples provide a crisp, refreshing counterpoint. On the right, a selection of artisan crackers, varying in shape and texture, offers a neutral base for tasting. Scattered around are small piles of toasted walnuts, their earthy aroma mingling with the cheese’s lactic tang. A small dish of golden honey sits near the Caerphilly, inviting a drizzle to enhance the flavors.

The overall impression is one of simple elegance, a celebration of the cheese and its carefully chosen accompaniments. The board is set on a dark, textured tablecloth, providing a contrasting background that makes the colors of the food pop.

Conclusion

In conclusion, mastering How to Make a Traditional Caerphilly Cheese is a journey of discovery and deliciousness. You’ve learned the essential steps, from the careful selection of ingredients to the patient art of aging. Armed with this knowledge, you can now craft your own authentic Caerphilly, sharing its unique flavors and textures with friends and family. Embrace the process, savor the results, and enjoy the timeless tradition of Caerphilly cheese making.