Embark on a journey into the fascinating world of cheesemaking, where the seemingly simple process of transforming milk into cheese is a delicate dance of science and art. At the heart of this transformation lies the crucial step of curd formation, the foundation upon which all cheese varieties are built. Understanding and mastering this process is key to crafting delicious and consistent cheeses, and that’s where the power of calcium chloride comes into play.

This guide, centered on How to Use Calcium Chloride to Improve Your Curd Set, will unravel the mysteries of this often-overlooked ingredient. We’ll explore how calcium chloride works, why it’s essential, and how to use it effectively to achieve a perfect curd set, regardless of the cheese you’re aiming to create. Prepare to discover the secrets behind achieving superior cheese texture, flavor, and overall quality.

Introduction to Calcium Chloride in Cheesemaking

Calcium chloride (CaCl₂) is a common additive in cheesemaking, playing a crucial role in the curd-forming process. It’s particularly beneficial when working with pasteurized milk, as this process can reduce the natural calcium content, which is essential for effective coagulation. This section will delve into the role of calcium chloride, its chemical properties relevant to cheesemaking, and the advantages it offers.

The Role of Calcium Chloride in Curd Formation

Calcium chloride primarily acts as a source of calcium ions (Ca²⁺) in milk. These ions are critical for the enzymatic action of rennet or other coagulants. They facilitate the interaction between casein proteins, which are the primary proteins in milk, causing them to aggregate and form a solid curd. Without sufficient calcium, the curd formation can be slow, weak, or even fail entirely.

Chemical Properties of Calcium Chloride Relevant to Dairy Processing

Calcium chloride is a white, crystalline solid that is highly soluble in water. Its solubility is crucial because it allows for easy and even distribution throughout the milk. The relevant chemical properties include:

- Molecular Formula: CaCl₂. This indicates that each molecule contains one calcium atom and two chlorine atoms.

- Molar Mass: 110.98 g/mol. This is the mass of one mole of calcium chloride.

- Hygroscopic Nature: Calcium chloride readily absorbs moisture from the air. This is important because it can affect its concentration if not stored properly.

- Dissociation in Water: When calcium chloride dissolves in water, it dissociates into calcium ions (Ca²⁺) and chloride ions (Cl⁻). This is represented by the following equation:

CaCl₂(s) → Ca²⁺(aq) + 2Cl⁻(aq)

The calcium ions are the key component that interacts with casein proteins.

Benefits of Using Calcium Chloride in Cheesemaking, Especially for Pasteurized Milk

Using calcium chloride in cheesemaking, especially with pasteurized milk, offers several advantages:

- Improved Curd Formation: It ensures a firm and consistent curd, leading to better cheese texture and yield. Pasteurized milk, due to the heat treatment, can have reduced calcium levels. Adding calcium chloride restores the calcium content, optimizing curd formation.

- Faster Coagulation: It accelerates the coagulation process, reducing the time required for the milk to set. This can be particularly helpful in commercial settings where time is of the essence.

- Increased Cheese Yield: By promoting a stronger curd, calcium chloride can contribute to a higher cheese yield. A well-formed curd traps more milk solids, leading to a more substantial final product.

- Enhanced Cheese Texture: The presence of sufficient calcium ions influences the final texture of the cheese. It contributes to a firmer and more desirable texture, which is particularly important for certain cheese varieties. For example, in cheddar cheese production, a firm curd is essential for the cutting and cheddaring processes.

- Compensation for Milk Variability: The natural calcium content in milk can vary depending on factors like the breed of the cow, the season, and the cow’s diet. Calcium chloride helps to standardize the calcium levels, providing more consistent results, even with varying milk sources.

Understanding Curd Set and Its Challenges

Curd set is a critical stage in cheesemaking, where the liquid milk transforms into a solid mass. This transformation, influenced by various factors, dictates the final texture and quality of the cheese. Understanding this process and the potential pitfalls is essential for consistent and successful cheesemaking.

The Process of Curd Formation

Curd formation is a fascinating biochemical process. It primarily involves the coagulation of milk proteins, specifically casein, to form a solid gel-like structure.The process typically unfolds in the following stages:

- Acidification: Lactic acid bacteria, either naturally present in the milk or added as a starter culture, consume lactose (milk sugar) and produce lactic acid. This lowers the pH of the milk.

- Enzyme Action (Optional): In many cheeses, rennet, an enzyme, is added. Rennet cleaves a specific bond in the casein molecules, causing them to destabilize.

- Coagulation: As the pH drops and/or rennet acts on the casein, the casein micelles (tiny protein structures suspended in the milk) lose their negative charge. This causes them to aggregate, forming a network that traps water and fat molecules. This network is the curd.

- Syneresis: Over time, the curd contracts, expelling whey (the liquid portion of the milk). The extent of syneresis affects the final moisture content of the cheese.

Common Problems Encountered During Curd Set

Several issues can arise during curd set, leading to undesirable cheese characteristics.

- Weak Curd: A weak curd is soft and easily breaks apart. This can lead to excessive moisture retention in the cheese, resulting in a mushy texture. Weak curds can be caused by several factors.

- Low protein content in the milk.

- Insufficient acidity development.

- Weak or inactive rennet.

- High milk fat content, which can interfere with protein coagulation.

- Slow Setting: The milk takes an unusually long time to coagulate. This can increase the risk of unwanted bacterial growth and affect the overall cheese flavor.

- Low starter culture activity.

- Insufficient rennet.

- Milk that is too cold.

- Presence of inhibitors that interfere with the rennet or starter culture.

- Failure to Set: In extreme cases, the milk may not coagulate at all. This can result from:

- Milk that has been excessively heated.

- Presence of antibiotics or other substances that inhibit bacterial or enzyme activity.

- Improper pH levels.

How Milk Quality Affects Curd Formation

The quality of the milk used is paramount to a successful curd set. Milk composition, particularly protein content, plays a significant role.

- Protein Content: Higher protein content generally leads to a firmer curd. Milk from certain breeds of cows, like Jersey cows, often have higher protein and fat content, resulting in richer, more flavorful cheese.

- Fat Content: While fat contributes to the flavor and texture of the cheese, excessive fat can interfere with curd formation, potentially leading to a softer curd.

- Acidity: The natural acidity of the milk, and the rate at which it develops, influences the speed and strength of the curd set. Fresh milk typically has a pH around 6.6 to 6.8.

- Presence of Inhibitors: Antibiotics or other substances present in the milk can inhibit the action of rennet or starter cultures, preventing proper curd formation.

- Milk Storage and Handling: The way milk is stored and handled can impact its quality. For instance, milk that is improperly cooled can encourage bacterial growth, altering its composition and affecting the curd set.

Why Use Calcium Chloride? Addressing Milk Issues

Calcium chloride is a valuable tool in cheesemaking, particularly when dealing with milk that presents challenges to a good curd set. Understanding the specific ways it addresses these issues is key to producing consistent and high-quality cheese. It primarily acts as a supplement to improve milk’s ability to coagulate effectively.

Addressing Milk Issues with Calcium Chloride

Milk composition can vary significantly depending on factors such as the breed of the animal, its diet, and the stage of lactation. These variations can lead to problems during cheesemaking, such as a weak or slow curd set. Calcium chloride helps mitigate these problems.

- Milk from Pasteurization: Pasteurization, while essential for food safety, can reduce the amount of calcium available in the milk, as it alters the natural calcium balance. Calcium chloride helps to restore the calcium levels, promoting a stronger curd.

- Seasonal Variations: Milk composition can change seasonally. During certain times of the year, milk may naturally have lower calcium levels or altered protein structures, leading to curdling problems. Calcium chloride provides a consistent calcium boost.

- Milk from Older Animals: As dairy animals age, the composition of their milk may change, potentially affecting curd formation. Calcium chloride can provide a consistent calcium level to aid in the coagulation process.

Calcium Chloride Compensating for Calcium Deficiencies

Calcium chloride’s primary function is to supplement the calcium content in milk, which can be deficient for several reasons. By adding calcium, cheesemakers can ensure a more predictable and robust curd set.

Calcium deficiency in milk can manifest as:

- A weak curd that easily breaks apart.

- A long time for the milk to coagulate.

- Excessive whey separation during the cheesemaking process.

Calcium chloride directly addresses these issues by providing the necessary calcium ions for the casein proteins in milk to bind together and form a solid curd.

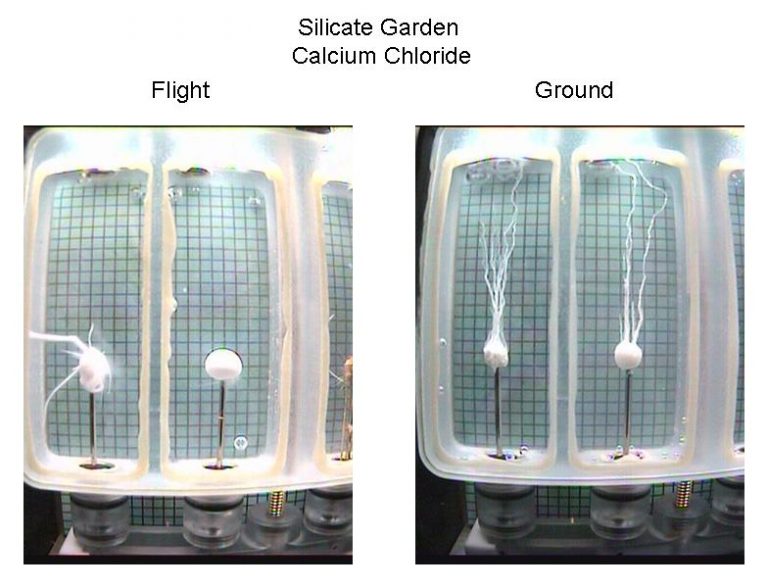

Comparing Curd Set with and Without Calcium Chloride

The difference in curd set between milk treated with calcium chloride and milk without it can be quite noticeable, especially when the milk has inherent challenges. This comparison helps illustrate the impact of calcium chloride.

Imagine two batches of milk from the same source, one with added calcium chloride and one without. Both are treated with the same rennet and at the same temperature.

- Without Calcium Chloride: The milk might take significantly longer to coagulate. The resulting curd may be soft, fragile, and prone to breaking apart easily. During cutting, the curd might crumble instead of forming clean, defined pieces.

- With Calcium Chloride: The milk will typically coagulate more quickly. The curd will be firmer and more elastic, making it easier to cut and handle. The curd will also release less whey during the cutting and draining process.

This comparison shows that calcium chloride enhances the efficiency of the cheesemaking process by providing a more consistent and reliable curd set, which in turn impacts the texture and quality of the final cheese product.

Determining the Right Dosage

Calculating the correct dosage of calcium chloride is crucial for achieving the desired curd set. Overdosing can lead to a tough, rubbery curd, while underdosing might result in a weak, unstable curd. The required amount varies depending on several factors, including the type of milk, its initial calcium content, and the specific cheese being made.

Factors Influencing Dosage

Several factors influence the ideal calcium chloride dosage for cheesemaking. Understanding these elements is essential for making informed decisions and achieving consistent results.

- Milk Type: The type of milk significantly impacts the required dosage. Cow’s milk generally requires less calcium chloride than goat’s milk, which naturally has lower calcium levels. Sheep’s milk, depending on the breed and season, can fall somewhere in between.

- Milk Source and Processing: Raw milk, pasteurized milk, and ultra-pasteurized (UHT) milk all have different calcium profiles. UHT milk, having undergone extreme heat treatment, often requires a higher dosage of calcium chloride because the heating process can denature proteins and reduce the milk’s ability to form a good curd.

- Milk Age: Older milk may have a slightly altered calcium balance. While not a primary factor, milk that has been stored for an extended period might benefit from a slight adjustment in calcium chloride dosage.

- Cheese Type: Different cheese varieties require different curd consistencies. Softer cheeses may require a slightly lower dosage compared to firmer cheeses, as they are less reliant on a very firm curd set.

Calculating Calcium Chloride Concentration

Accurately calculating the concentration of calcium chloride is essential for consistent results. Here’s a step-by-step guide:

- Determine the Milk Volume: Accurately measure the volume of milk you’re using in liters or gallons.

- Check the Calcium Chloride Concentration: Calcium chloride typically comes in a solution of 30% or 33%. Make sure you know the concentration of the solution you are using. This information should be clearly stated on the product label.

- Calculate the Required Dosage: A general starting point is to add calcium chloride at a rate of 1/4 to 1/2 teaspoon (1.25 to 2.5 ml) of a 30% solution per gallon (3.8 liters) of milk, or 1/8 to 1/4 teaspoon (0.6 to 1.25 ml) of a 33% solution per gallon. This is a starting point, and adjustments may be needed.

- Use the Following Formula: This formula helps determine the precise amount to use, taking into account the concentration of your calcium chloride solution and the milk volume:

Dosage (ml) = (Milk Volume (liters)

- Desired Dosage (ml/liter)) / Calcium Chloride Concentration (%)

- 100

- 0.25 ml/liter) / 30%

- 100 = 0.33 ml

- Dilute and Add: Dilute the calculated amount of calcium chloride in a small amount of cool, non-chlorinated water (e.g., 1/4 cup) before adding it to the milk. This helps ensure even distribution. Stir the milk gently for about a minute after adding the calcium chloride.

- Monitor and Adjust: Observe the milk’s behavior after adding the rennet. If the curd sets too quickly and becomes very firm, reduce the dosage next time. If the curd is slow to set or remains weak, slightly increase the dosage.

For example, if you are using 4 liters of milk, and the desired dosage is 0.25 ml/liter, and your calcium chloride solution is 30%:

Dosage (ml) = (4 liters

Dosage Recommendations Table

This table provides general dosage recommendations for different milk types and batch sizes. Remember these are starting points, and you may need to adjust based on the specific milk and desired cheese type.

| Milk Type | Batch Size (Liters) | 30% Calcium Chloride Solution (ml) | 33% Calcium Chloride Solution (ml) |

|---|---|---|---|

| Pasteurized Cow’s Milk | 4 | 0.5 – 1.0 | 0.4 – 0.8 |

| Pasteurized Goat’s Milk | 4 | 1.0 – 1.5 | 0.8 – 1.2 |

| UHT Milk (Cow or Goat) | 4 | 1.5 – 2.5 | 1.2 – 2.0 |

| Raw Milk (Cow or Goat) | 4 | 0.25 – 0.75 | 0.2 – 0.6 |

Preparing Calcium Chloride Solution

Preparing your calcium chloride solution correctly is crucial for successful cheesemaking. A properly made solution ensures accurate dosage and consistent results in your curd set. This section details the recommended methods, handling procedures, and safety precautions for working with calcium chloride solutions.

Recommended Methods for Preparing Calcium Chloride Solution

Accurately preparing the calcium chloride solution is vital for the cheesemaking process. The following methods Artikel how to achieve the desired concentration effectively.

The standard concentration for cheesemaking is typically a 30% solution. This means 30 grams of calcium chloride are dissolved in enough water to make a total volume of 100 milliliters. This concentration provides a good balance of effectiveness and ease of use.

- Weighing Calcium Chloride: Accurately measure the calcium chloride crystals using a digital scale. The scale should be capable of measuring in grams with at least one decimal place of precision (e.g., 0.1g). For a 30% solution, weigh out the required amount of calcium chloride crystals based on the total volume you need. For example, to make 100 ml of a 30% solution, you’d weigh 30 grams of calcium chloride.

- Using Distilled or Filtered Water: Use distilled or filtered water. Tap water can contain minerals and impurities that may interfere with the cheesemaking process. These impurities can affect the calcium chloride’s solubility and the overall quality of the solution.

- Dissolving Calcium Chloride: Slowly add the calcium chloride crystals to the water, stirring constantly. Stir until all the crystals are completely dissolved. Calcium chloride dissolves readily in water, but stirring ensures even distribution and prevents clumping.

- Measuring the Final Volume: Once the calcium chloride is completely dissolved, measure the final volume accurately using a graduated cylinder or a volumetric flask. Remember that dissolving the calcium chloride might slightly decrease the volume of the solution. For instance, if you dissolve 30 grams of calcium chloride in 70 ml of water, the final volume should be close to 100 ml.

- Calculating the Correct Dosage: Before using the solution, double-check your calculations for the appropriate dosage per gallon or liter of milk. This ensures the correct amount of calcium chloride is added to the milk, leading to a good curd set.

Proper Handling and Storage Procedures for Calcium Chloride Solutions

Proper handling and storage are crucial to maintain the solution’s effectiveness and ensure its safe use. Following these procedures will help preserve the solution’s quality and prevent contamination.

- Use Food-Grade Calcium Chloride: Always use food-grade calcium chloride. Industrial-grade calcium chloride may contain impurities that are not suitable for consumption. The food-grade variety is specifically manufactured to meet standards for food applications.

- Labeling the Solution: Clearly label the container with the date of preparation, the concentration of the solution (e.g., 30%), and the contents (Calcium Chloride Solution). This is important for tracking and identifying the solution.

- Storing in an Airtight Container: Store the solution in an airtight, food-grade container. This prevents contamination and evaporation, which can alter the concentration of the solution. Amber or opaque containers are ideal because they protect the solution from light.

- Storage Location: Store the solution in a cool, dark place, away from direct sunlight and extreme temperatures. A pantry or a cupboard is suitable.

- Shelf Life: A properly stored calcium chloride solution can last for several months, or even a year, if stored correctly. However, check the solution for any signs of cloudiness or precipitation before each use, as these could indicate contamination or degradation.

Safety Precautions to be Followed When Working with Calcium Chloride

Safety should always be a priority when working with chemicals, including calcium chloride. The following safety precautions are essential to protect yourself from potential hazards.

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), including:

- Eye Protection: Wear safety goggles or a face shield to protect your eyes from splashes.

- Gloves: Use chemical-resistant gloves (e.g., nitrile or latex) to protect your skin from contact with the solution.

- Apron: Wear a protective apron to prevent spills from reaching your clothing and skin.

- Work in a Well-Ventilated Area: Prepare the solution in a well-ventilated area to prevent the inhalation of any fumes or dust that may be released. Proper ventilation is critical for minimizing exposure to any airborne particles.

- Avoid Contact with Skin and Eyes: Calcium chloride can cause irritation to the skin and eyes. If the solution comes into contact with your skin or eyes, immediately flush the affected area with plenty of water for at least 15 minutes. Seek medical attention if irritation persists.

- Avoid Ingestion: Do not ingest the calcium chloride solution. If ingested, seek medical attention immediately. Calcium chloride can cause gastrointestinal distress.

- Clean Up Spills Promptly: If a spill occurs, clean it up immediately. Use plenty of water to dilute the spill and wipe it up with absorbent materials. Dispose of the absorbent materials properly.

- Keep Out of Reach of Children and Pets: Store calcium chloride and its solutions in a secure location, out of the reach of children and pets, to prevent accidental ingestion or contact.

- Read the Safety Data Sheet (SDS): Before working with calcium chloride, review the Safety Data Sheet (SDS) for detailed information on the chemical’s hazards, handling procedures, and first-aid measures. The SDS provides essential information for safe handling.

Step-by-Step Procedure: Adding Calcium Chloride to Milk

Adding calcium chloride to your milk might seem simple, but following a precise procedure is key to achieving a successful curd set. Proper timing and mixing are crucial for ensuring the calcium chloride is evenly distributed and effective. This section Artikels the step-by-step process, helping you avoid common pitfalls and achieve consistent results in your cheesemaking.

Adding Calcium Chloride to Milk: The Process

The following steps detail the process of adding calcium chloride to your milk. Precision is critical for the best results.

- Preparation of Milk: Begin with your milk, whether pasteurized or raw, ensuring it is at the appropriate temperature for cheesemaking, typically around 86-90°F (30-32°C) for most cheeses. This temperature allows the cultures and rennet to function optimally. Use a thermometer to verify.

- Calculating the Dosage: Based on your milk volume and the concentration of your calcium chloride solution (refer to the previous section on determining the right dosage), calculate the precise amount of calcium chloride solution needed. It is best to use a kitchen scale for accurate measurements.

- Adding the Solution: Gently add the calculated amount of calcium chloride solution to the milk.

- Gentle Mixing: Immediately after adding the calcium chloride, gently stir the milk for approximately 30-60 seconds. This is crucial to ensure the calcium chloride is evenly dispersed throughout the milk. Avoid over-stirring, which can disrupt the milk’s structure.

- Resting Period: Allow the milk to rest undisturbed for a few minutes. This allows the calcium chloride to integrate with the milk proteins.

- Adding Cultures (if applicable): If your cheese recipe calls for adding cultures before the rennet, add them after the calcium chloride has been mixed in and allowed to rest. Follow the manufacturer’s instructions for your specific culture.

- Adding Rennet: Follow your recipe to add the rennet after the calcium chloride and cultures (if applicable).

- Gentle Mixing (again): Gently stir the milk for another 30-60 seconds after adding the rennet to distribute it evenly.

- Incubation: Allow the milk to incubate undisturbed, according to your recipe, until a clean break is achieved.

Common Mistakes to Avoid

Several common mistakes can undermine the effectiveness of calcium chloride addition. Awareness of these errors helps prevent them.

- Incorrect Dosage: Using too much or too little calcium chloride will affect the curd set. Too much can lead to a rubbery curd, while too little may not provide sufficient improvement. Always measure accurately.

- Improper Mixing: Inadequate mixing results in uneven distribution of calcium chloride, leading to inconsistent curd formation. Over-stirring can break down the milk’s structure.

- Adding Calcium Chloride to Hot Milk: Adding calcium chloride to milk that is too hot (above the recommended temperature for your cheese type) can denature the milk proteins, affecting the curd set.

- Adding Calcium Chloride to Cold Milk: Adding calcium chloride to milk that is too cold will slow down the activity of the cultures and rennet.

- Not Allowing the Milk to Rest: Failing to allow the milk to rest after adding calcium chloride and before adding the rennet may not allow sufficient time for the calcium chloride to react with the milk proteins.

- Using Impure Calcium Chloride: Always use food-grade calcium chloride to ensure safety and consistent results.

Practical Examples: Calcium Chloride Application in Different Cheese Types

Calcium chloride is a versatile ingredient in cheesemaking, impacting curd formation and final cheese characteristics across a wide range of styles. Its application varies depending on the desired cheese type, milk quality, and specific challenges encountered during the cheesemaking process. Understanding these nuances is crucial for achieving consistent and desirable results.

Calcium Chloride Application in Various Cheese Types

The use of calcium chloride varies significantly based on the cheese type. Here are some specific examples:

Cheddar: Calcium chloride is often added to cheddar cheese to improve curd firmness, especially when using pasteurized milk. This helps in achieving a clean break and efficient whey expulsion during the cheddaring process. The resulting cheese has a more consistent texture and improved aging characteristics.

Mozzarella: In mozzarella production, calcium chloride enhances curd formation and elasticity, crucial for the characteristic stretch and melt of this cheese.It helps to achieve the desired texture and prevent the cheese from becoming overly soft or breaking down during the stretching phase.

Feta: Calcium chloride can be used to firm up the curd in feta cheese, which often uses pasteurized milk. This helps create a more stable curd that can be cut and salted without excessive breakage.The result is a cheese with a better texture and reduced whey expulsion during brining.

Brie and Camembert: For these soft-ripened cheeses, calcium chloride aids in achieving a firmer curd that holds its shape during the initial stages of ripening. This is particularly important when using milk that might be lower in calcium.The use of calcium chloride can help to control the texture and prevent the cheese from becoming too runny too early in the aging process.

Swiss-Style Cheeses: In the production of Swiss-style cheeses, calcium chloride can contribute to a firmer curd and help facilitate the formation of the characteristic “eyes” or holes.This is especially important when using milk that has been treated in ways that might reduce calcium levels.

Differences in Application for Soft vs. Hard Cheeses

The application of calcium chloride differs significantly between soft and hard cheeses due to their varying processing techniques and desired textures.

- Dosage: Soft cheeses generally require a lower concentration of calcium chloride compared to hard cheeses. The goal in soft cheese production is often to provide enough calcium to achieve a stable curd without making it overly firm, which could result in a less desirable texture. Hard cheeses, on the other hand, often benefit from a higher concentration to promote a firmer curd, enabling efficient whey expulsion and the development of the desired body and texture during aging.

- Timing: The timing of calcium chloride addition is generally consistent across cheese types; it is usually added to the milk before the addition of the culture and rennet. This allows the calcium chloride to be evenly distributed throughout the milk and to interact with the casein proteins to promote curd formation.

- Impact on Texture: In soft cheeses, calcium chloride primarily contributes to a slightly firmer curd that aids in handling and shaping. The final texture is still expected to be soft and creamy. In hard cheeses, calcium chloride is crucial for achieving the firm curd necessary for the cheddaring, pressing, and aging processes, leading to a more dense and structured cheese.

- Impact on Flavor: While calcium chloride itself is flavorless at the concentrations used in cheesemaking, it indirectly influences flavor by affecting the curd structure and whey expulsion. A well-formed curd, aided by calcium chloride, can lead to a more efficient removal of whey, which in turn affects the concentration of flavor compounds in the final cheese.

Calcium Chloride’s Effects on Texture and Flavor Profile

Calcium chloride’s impact extends beyond just curd formation, influencing both the texture and flavor of the final cheese.

- Texture Enhancement:

- In hard cheeses, calcium chloride promotes a firmer, more cohesive curd, which leads to a denser texture. This is crucial for cheeses like cheddar, where the curd undergoes cheddaring and pressing. The firm curd helps the cheese withstand these processes and retain its shape, resulting in a cheese with a characteristic firm body.

- In soft cheeses, the impact on texture is more subtle, helping to achieve a slightly firmer curd that aids in handling and shaping. The resulting texture remains soft and creamy, but with a more controlled structure.

- For example, in mozzarella, calcium chloride contributes to the cheese’s elasticity, enabling it to stretch and melt properly.

- Flavor Profile Influence:

- Calcium chloride indirectly affects flavor by influencing whey expulsion. A well-formed curd allows for efficient whey drainage, which removes excess lactose and other compounds that can contribute to off-flavors.

- The efficient removal of whey can also concentrate the flavor compounds in the cheese, leading to a more pronounced and complex flavor profile.

- The texture itself can also influence the perception of flavor. A firmer cheese may have a more concentrated flavor, while a softer cheese might have a more delicate flavor.

- Examples:

- In cheddar, the firm curd facilitated by calcium chloride contributes to a sharper, more complex flavor as the cheese ages.

- In mozzarella, the improved texture enhances the overall eating experience, allowing for a better melt and stretch, which complements the cheese’s mild flavor.

- In feta, the firmer curd helps to prevent the cheese from becoming overly salty and crumbly during brining, contributing to a balanced flavor profile.

Troubleshooting Curd Set Problems

Even with the use of calcium chloride, achieving the perfect curd set can sometimes be challenging. Several factors can influence the process, and it’s essential to be prepared to troubleshoot potential issues. This section will delve into common problems that might arise and provide practical solutions to ensure a successful curd set.

Curd Too Soft

A curd that is too soft is a common problem, often indicating insufficient protein coagulation. This can lead to cheese that is difficult to handle, drains poorly, and has a weak texture.

- Insufficient Calcium Chloride: Ensure you’ve used the correct dosage of calcium chloride. If you suspect you used too little, consider increasing the amount in future batches, but be cautious and make small adjustments.

- Low Milk Protein Content: Milk with a low protein content will naturally produce a softer curd. Milk from different breeds of cows can vary in protein content. Using milk that is not fresh or has been diluted can also result in a lower protein content.

- Insufficient Rennet: The rennet enzyme is crucial for coagulation. Make sure your rennet is fresh and properly stored. Using too little rennet, or rennet that has lost its potency, will result in a weak curd.

- Incorrect Rennet Temperature: The temperature of the milk when rennet is added is critical. If the milk is too cold, the rennet will not work effectively. Ensure the milk is at the correct temperature specified for your cheese recipe.

- Milk pH Issues: Milk pH plays a significant role in curd formation. Milk that is too alkaline (high pH) may result in a soft curd. Acidifying the milk slightly before adding rennet can help. Using a starter culture can help lower the pH.

Curd Too Hard

A curd that is too hard can result in cheese with a rubbery texture, excessive moisture loss, and a less desirable flavor profile.

- Excess Calcium Chloride: Overuse of calcium chloride is a common cause of a hard curd. Always adhere to the recommended dosage and avoid exceeding it.

- High Milk Protein Content: Milk with a very high protein content can lead to a firmer curd. This is often less of an issue, but it can contribute.

- Excess Rennet: Using too much rennet can also cause the curd to set too firmly. Ensure you are measuring the rennet accurately.

- Over-Acidification: Milk that is too acidic (low pH) can result in a hard curd. Monitor the pH of the milk, especially when using starter cultures.

- High Cooking Temperatures: If you’re cooking the curds, excessive heat can expel too much moisture and toughen the curd. Carefully follow the temperature guidelines for your cheese recipe.

Slow Curd Set

A slow curd set can be frustrating, leading to extended processing times and potentially affecting the final cheese quality.

- Insufficient Calcium Chloride: The most common reason for a slow curd set is insufficient calcium chloride. Double-check the dosage and make sure you are using the correct amount.

- Weak Rennet: Old or improperly stored rennet may lose its potency. Ensure your rennet is fresh and stored correctly, following the manufacturer’s instructions.

- Low Milk Temperature: The milk needs to be at the proper temperature for the rennet to work effectively. Refer to your recipe for the correct temperature range.

- Milk Quality Issues: Milk that is old, has been frozen, or has been treated with antibiotics can sometimes interfere with the rennet’s action. Ensure you are using fresh, high-quality milk.

- Contamination: The presence of inhibitors, such as sanitizers or cleaning agents, in your equipment can inhibit rennet activity. Thoroughly clean and rinse all equipment before use.

Alternative Methods and Considerations

Improving curd set is a multifaceted process, and while calcium chloride is a valuable tool, it’s not the only approach. Understanding alternative methods and the interplay of various factors is crucial for consistent and successful cheesemaking. This section explores other techniques and ingredients that can enhance curd formation, providing a comprehensive understanding of the cheese-making process.

Alternative Ingredients for Curd Set

There are several ingredients that can be used to improve curd set, each with its own mechanism of action and suitability depending on the cheese type. These alternatives often address similar issues as calcium chloride, such as milk that is low in calcium or contains other components that interfere with curd formation.

- Acidification: Adjusting the milk’s pH is a primary method for initiating curd formation. Acidification can be achieved through:

- Direct Acidification: Adding a food-grade acid, such as citric acid, lactic acid, or vinegar, directly to the milk. This is common in making fresh cheeses like paneer or ricotta.

- Indirect Acidification: Using a starter culture containing lactic acid bacteria. These bacteria consume lactose (milk sugar) and produce lactic acid as a byproduct, gradually lowering the pH over time. This is the foundation of most aged cheeses.

The optimal pH for rennet activity and curd formation varies depending on the cheese type. For example, a lower pH is often required for soft cheeses compared to hard cheeses.

- Milk Protein Concentrates (MPCs) and Milk Protein Isolates (MPIs): These are dairy ingredients that are added to increase the protein content of the milk. Increased protein content can lead to a firmer curd. MPCs and MPIs are particularly useful when making cheese from milk with low protein levels. They are often used in commercial cheesemaking to standardize milk composition.

- Calcium Phosphate: While calcium chloride provides soluble calcium, calcium phosphate can be used in some cases. However, calcium phosphate is less soluble than calcium chloride, and its effectiveness depends on the specific form and the milk’s composition.

- Other Minerals: Certain trace minerals can influence curd formation, although their impact is usually less significant than calcium. The specific mineral composition of the milk, affected by the cow’s diet and environment, can influence curd strength and syneresis (whey expulsion).

Comparing Calcium Chloride to Other Methods

Each method for improving curd set has its strengths and weaknesses. The best choice depends on the specific cheese being made, the characteristics of the milk, and the cheesemaker’s preferences.

| Method | Mechanism | Advantages | Disadvantages | Typical Use Cases |

|---|---|---|---|---|

| Calcium Chloride | Increases soluble calcium, aiding in casein micelle interaction. | Effective in milk with low calcium, improves curd firmness, enhances syneresis. | Can lead to a slightly bitter taste if overused, does not address other milk quality issues. | Most hard cheeses, when milk calcium is deficient, or to improve curd texture. |

| Acidification (Direct) | Lowers pH, denaturing proteins and causing them to coagulate. | Simple and quick for fresh cheeses. | May result in a tart flavor, limited applicability to aged cheeses. | Paneer, ricotta, and other fresh, acidic cheeses. |

| Acidification (Indirect) | Lactic acid bacteria produce lactic acid, lowering pH. | Develops complex flavors, crucial for many cheese types. | Requires time, dependent on starter culture activity, pH control is critical. | Cheddar, Gouda, and other aged cheeses. |

| MPCs/MPIs | Increases protein content, strengthening the curd matrix. | Improves curd yield and texture, can be used to standardize milk composition. | May affect flavor, can be expensive. | Commercial cheesemaking, when milk protein content is low. |

Influence of Starter Culture and Rennet

The starter culture and rennet are critical factors in curd formation, and their interaction with calcium chloride and other additives significantly impacts the final cheese.

- Starter Culture: The starter culture provides the lactic acid bacteria that lower the milk’s pH. This acidification is essential for rennet activity and curd formation. The specific type of starter culture influences the flavor, texture, and rate of acidification.

For example, a mesophilic culture is often used for cheddar, while a thermophilic culture is used for mozzarella. The activity of the starter culture directly affects the time required for curd formation.

- Rennet: Rennet contains enzymes, primarily chymosin, that cleave kappa-casein, destabilizing the casein micelles and allowing them to aggregate and form a curd. Rennet concentration and quality, along with the milk’s pH and calcium content, influence the speed and firmness of the curd.

The type of rennet (animal, vegetable, or microbial) and its strength (determined by the manufacturer) are crucial for consistent results.

Rennet is typically measured in units of activity. Follow the manufacturer’s instructions for the correct dosage based on the milk volume and desired curd firmness.

- Interaction: The interplay between the starter culture, rennet, and calcium chloride is complex. The starter culture’s acidification lowers the pH, which affects the rennet’s activity. Calcium chloride provides the necessary calcium ions for the rennet to function optimally.

For example, in making a hard cheese like cheddar, a slower acidification rate is often desired to allow for more even moisture distribution and flavor development.

Calcium chloride can be used to improve the curd set, especially if the milk is low in calcium, while carefully controlling the starter culture’s activity to achieve the desired acidity.

Visual Representation: Enhancing Understanding

Visual aids significantly improve comprehension in cheesemaking. They offer a clear understanding of processes that might be difficult to grasp through text alone. This section provides illustrative examples of key concepts related to calcium chloride use in curd formation.

Curd Formation: With and Without Calcium Chloride

Visualizing the impact of calcium chloride is crucial. The following description details the differences in curd formation with and without its use.Imagine two side-by-side diagrams, each representing a cross-section of milk undergoing the cheesemaking process.* Diagram 1: Without Calcium Chloride: This diagram shows a less organized curd structure. The casein proteins, responsible for curd formation, appear loosely aggregated and unevenly distributed.

The whey, the liquid byproduct, is dispersed throughout the curd in larger pockets. The overall texture is likely to be soft, fragile, and prone to breaking. This scenario is often observed when milk lacks sufficient calcium or when other factors hinder proper curd formation.* Diagram 2: With Calcium Chloride: This diagram displays a more compact and uniform curd structure. The casein proteins are tightly packed and well-connected, forming a cohesive network.

The whey is present in smaller, more evenly distributed pockets. The curd has a firmer, more resilient texture. This illustrates how calcium chloride helps create a stronger curd, making it easier to cut and handle during subsequent cheesemaking steps. The improved structure leads to a better cheese yield and a more desirable final product.

Equipment and Setup for Adding Calcium Chloride

Proper equipment and setup are essential for safe and effective calcium chloride application. This section Artikels the necessary tools and their arrangement.The image depicts a clean and organized cheesemaking station. The central focus is on the milk vat, a stainless steel container filled with milk.* Calcium Chloride Solution: A small, clear glass or plastic container holds the diluted calcium chloride solution.

The solution is clearly labeled with the concentration (e.g., “1% Calcium Chloride Solution”). A measuring device, such as a graduated cylinder or a syringe, is positioned next to the container for precise measurement of the dosage.* Measuring Tools: Next to the calcium chloride solution, there are accurate measuring tools. The image shows a calibrated pipette or syringe.* Stirring Tool: A clean stainless steel or food-grade plastic whisk or spoon rests nearby.

This tool is used to gently stir the milk after the calcium chloride solution is added, ensuring even distribution.* Thermometer: A food-grade thermometer, preferably digital, is placed within easy reach. The thermometer is used to monitor the milk temperature throughout the process, ensuring it is within the correct range for the specific cheese being made.* Safety Precautions: The image highlights safety precautions.

Gloves and safety glasses are recommended.* Cleanliness: The overall impression is one of cleanliness and organization, emphasizing the importance of hygiene in cheesemaking.

Ideal Curd Texture for Cutting

Understanding the ideal curd texture is critical for successful cheesemaking. The following describes the visual characteristics of a well-set curd, ready for cutting.The image showcases a close-up view of the milk in the vat after coagulation. The surface of the milk has transformed into a solid mass, and this is the curd.* Firmness: The curd has a firm, yet slightly yielding texture.

When gently touched with a clean finger, the surface should feel solid but not rubbery. There should be a slight give, indicating that the curd is not overset.* Clean Break: When the surface is gently pushed with a finger or a knife, a clean break should be observed. This indicates that the curd has sufficient strength to hold its structure.

The edges of the cut should be relatively smooth, with minimal whey separation at this stage.* Whey Separation: Small pockets of clear whey should be visible on the surface and within the curd. Excessive whey separation indicates that the curd may have been cut too early or that the setting process was too rapid.* Uniformity: The curd appears relatively uniform in texture, with no large clumps or inconsistencies.

This suggests that the milk coagulated evenly.

Last Point

From understanding the science behind curd formation to mastering the practical application of calcium chloride, this exploration offers a comprehensive guide to enhancing your cheesemaking skills. By understanding the nuances of milk, dosage calculations, and troubleshooting techniques, you are well-equipped to consistently produce high-quality cheese. With the knowledge gained, you’re now empowered to elevate your cheesemaking endeavors, ensuring consistently superior results and delicious cheeses.

So, go forth and create!